Engine waste heat power recovery system and method

A recovery system and recovery method technology, applied in the field of engines, can solve problems such as not being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

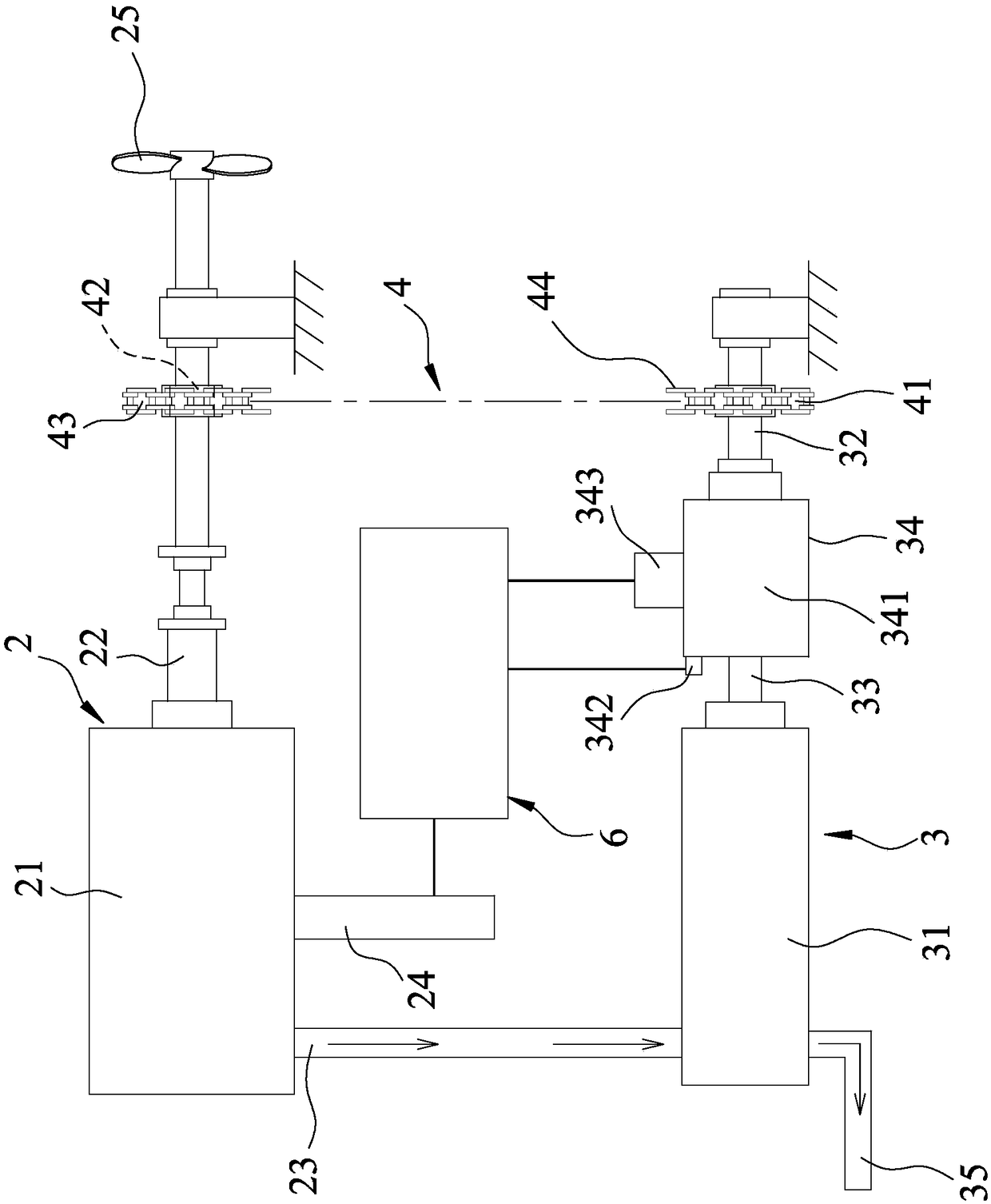

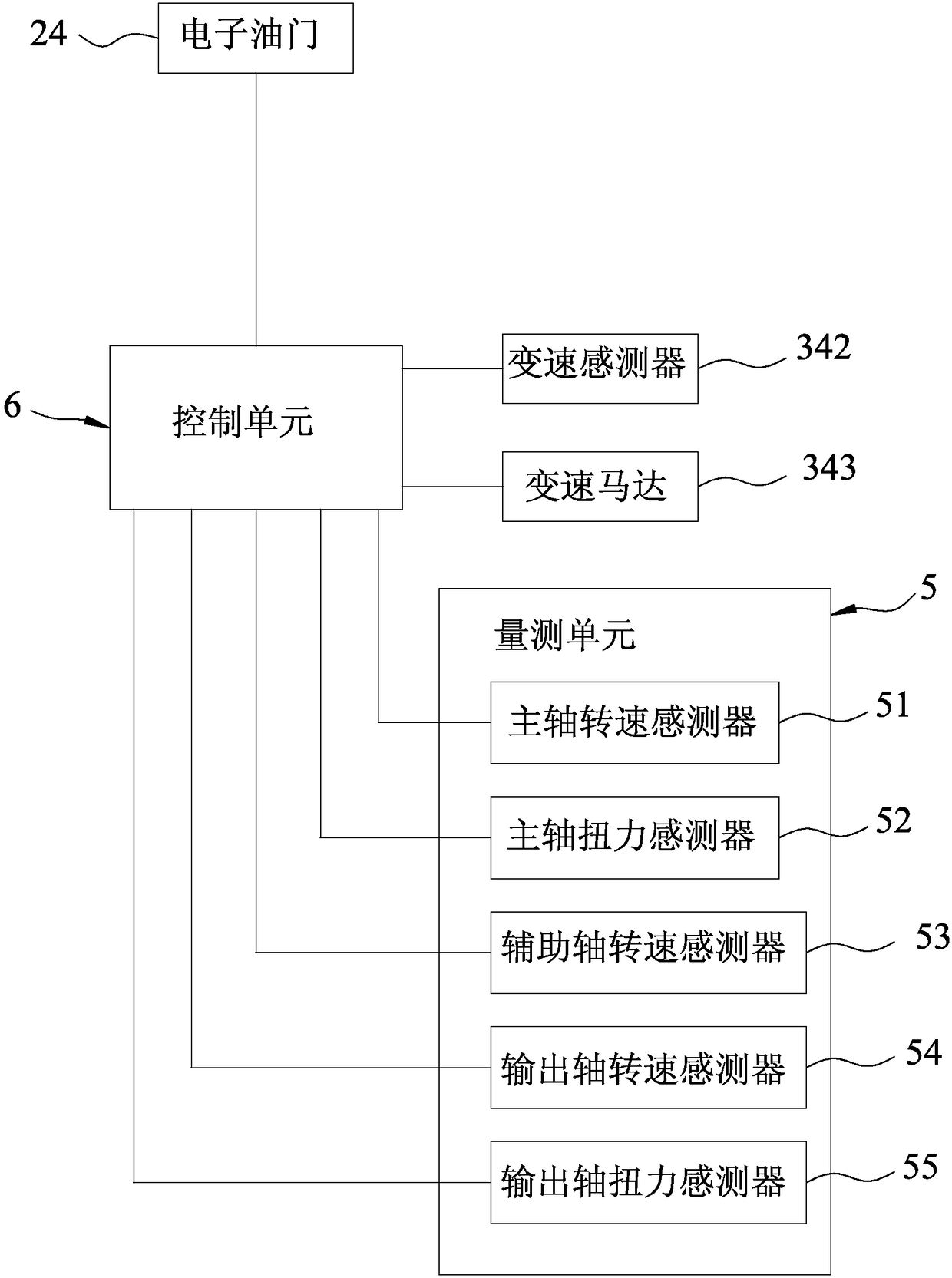

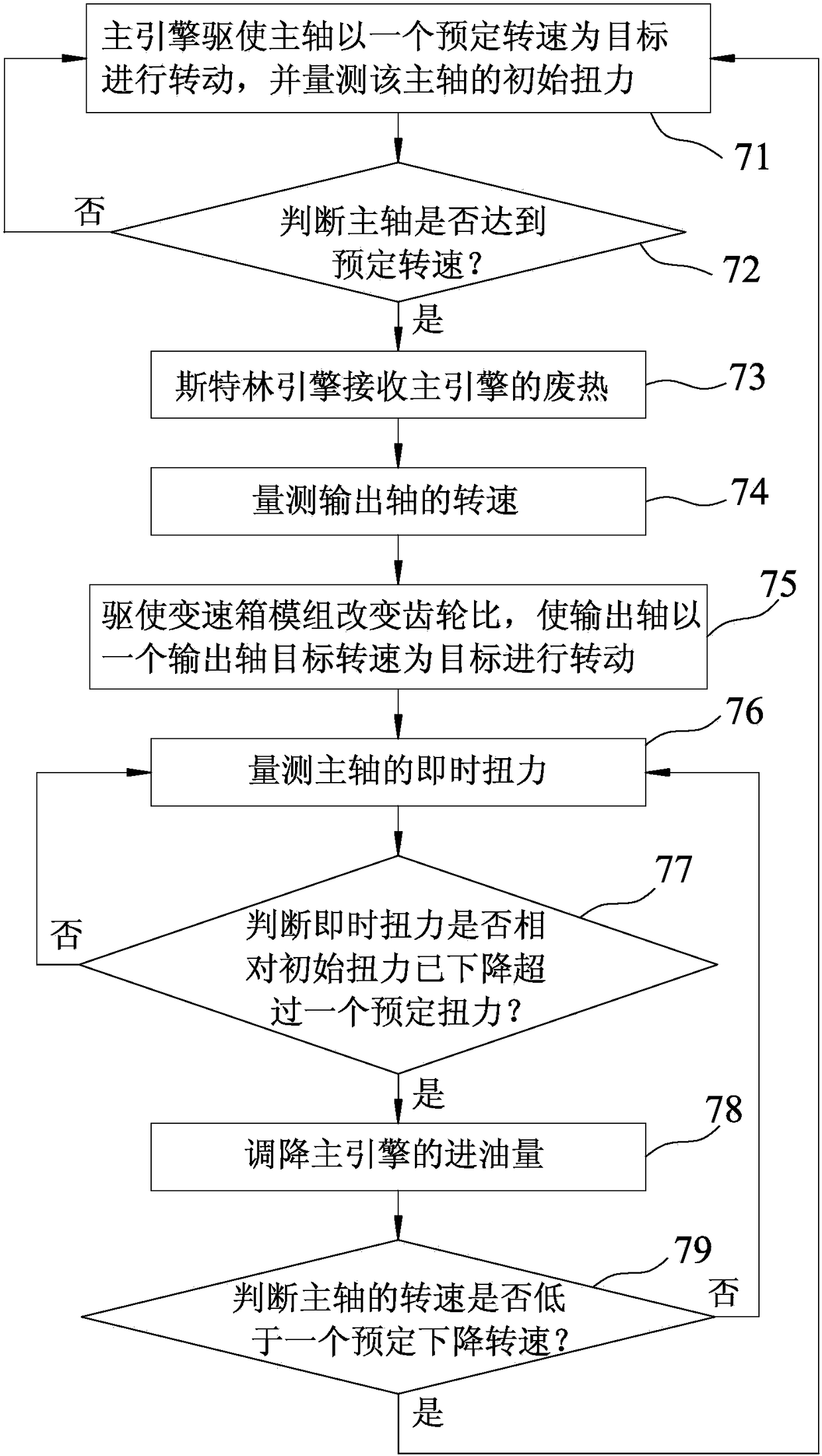

[0021] refer to figure 1 , 2 , 3, an embodiment of the engine waste heat power recovery system and method of the present invention, the engine waste heat power recovery system includes a main power unit 2, an auxiliary power unit 3, a transmission unit 4, a measurement unit 5, and a control Unit 6.

[0022] The main power unit 2 includes a main engine 21, a main shaft 22 connected and driven to rotate by the main engine 21, a heat pipe 23 connected to the main engine 21, and a control unit 6 connected to the main engine 21 and electrically connected To adjust the electronic throttle 24 of the fuel intake of the main engine 21 .

[0023] The auxiliary power unit 3 includes a Stirling engine 31 connected to the heat pipe 23, an output shaft 32 that is rotated in conjunction with the Stirling engine 31, and an auxiliary shaft that is connected and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com