A kind of die steel processing and smelting method

A smelting method and die steel technology, applied in the field of smelting, can solve the problems of insufficient durability, heat resistance and wear resistance, and deformation during use, so as to improve the overall mechanical properties, reduce thermal cracks, and have strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

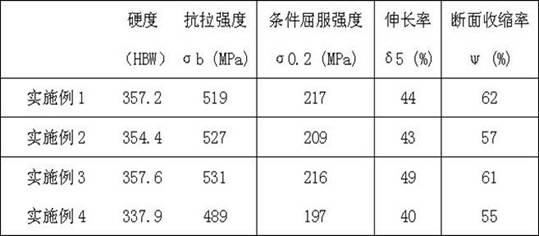

Examples

Embodiment 1

[0027] A method for processing and smelting die steel, comprising the following steps:

[0028] Step 1, collecting scrap steel for centralized cleaning and processing for standby;

[0029] Step 2, adding steel scrap into the intermediate frequency furnace, raising the temperature for smelting, and controlling the temperature of the furnace to 1500°C;

[0030] Step 3: After controlling the intermediate frequency furnace to keep the temperature for smelting for 3 hours, add slag to adjust the chemical composition of molten steel. The composition and weight percentage of molten steel are: C: 0.36%, W: 0.8%, Mo: 0.5%, Cr: 4.5 %, V: 0.6%, Mn: 0.3%, Si: 0.85%, P: 0.02% and S: 0.01%, the rest is Fe and unavoidable impurities, then inject a sufficient amount of oxygen into the intermediate frequency furnace, and add the oxidant , make the molten steel undergo oxidation reaction, remove gas, non-metallic impurities and various impurities in the molten steel, and use the temperature re...

Embodiment 2

[0038] A method for processing and smelting die steel, comprising the following steps:

[0039] Step 1, collecting scrap steel for centralized cleaning and processing for standby;

[0040] Step 2, adding steel scrap into the intermediate frequency furnace, raising the temperature for smelting, and controlling the temperature of the furnace to 1600°C;

[0041]Step 3: After controlling the intermediate frequency furnace to keep the temperature for smelting for 5 hours, add slag to adjust the chemical composition of molten steel. The composition and weight percentage of molten steel are: C: 0.43%, W: 1.0%, Mo: 0.7%, Cr: 5.5 %, V: 0.8%, Mn: 0.5%, Si: 1.20%, P: 0.03% and S: 0.015%, the rest is Fe and unavoidable impurities, then inject a sufficient amount of oxygen into the intermediate frequency furnace, and add the oxidant , make the molten steel undergo oxidation reaction, remove gas, non-metallic impurities and various impurities in the molten steel, and use the temperature re...

Embodiment 3

[0049] A method for processing and smelting die steel, comprising the following steps:

[0050] Step 1, collecting scrap steel for centralized cleaning and processing for standby;

[0051] Step 2, adding steel scrap into the intermediate frequency furnace, raising the temperature for smelting, and controlling the temperature of the furnace to 1550°C;

[0052] Step 3: After controlling the intermediate frequency furnace to keep the temperature for 4 hours, add slag to adjust the chemical composition of molten steel. The composition and weight percentage of molten steel are: C: 0.39%, W: 0.9%, Mo: 0.6%, Cr: 5 %, V: 0.7%, Mn: 0.4%, Si: 1.0%, P: 0.025% and S: 0.013%, the rest is Fe and unavoidable impurities, then inject a sufficient amount of oxygen into the intermediate frequency furnace, and add oxidant , make the molten steel undergo oxidation reaction, remove gas, non-metallic impurities and various impurities in the molten steel, and use the temperature released during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com