A preparation method of Cadi nodular cast iron resistant to minus 40°C low temperature impact

A ductile iron, low-temperature impact technology, applied in the direction of improving process efficiency, can solve the problem of low impact power value, and achieve the effects of increasing the pressure in the bag, sufficient spheroidization, and increasing the nucleation ability of graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

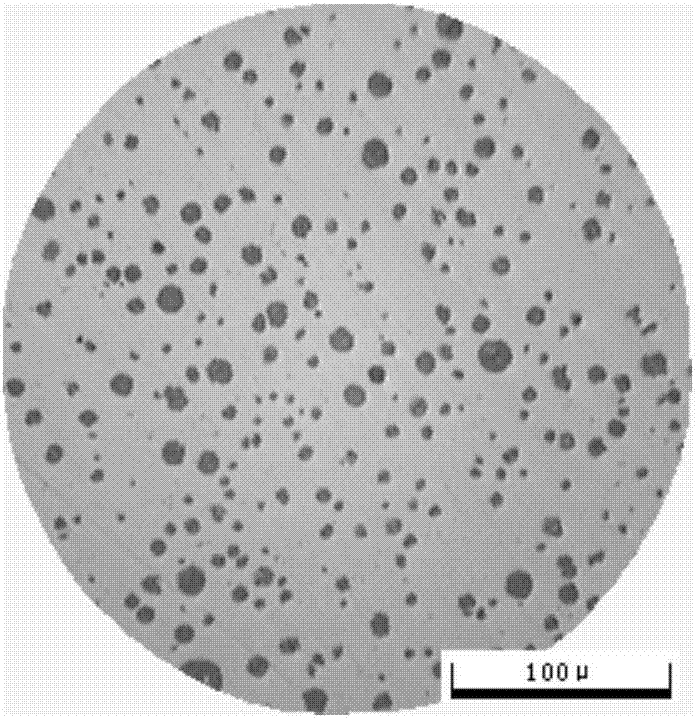

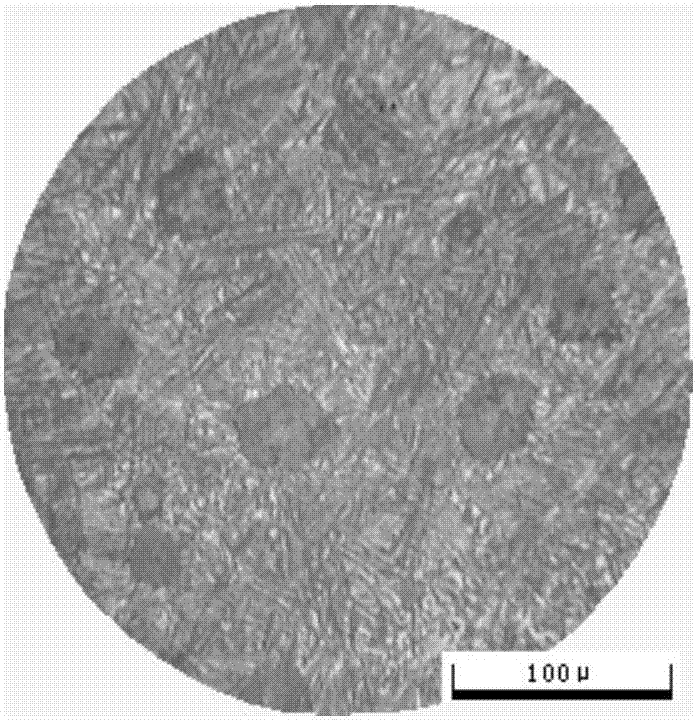

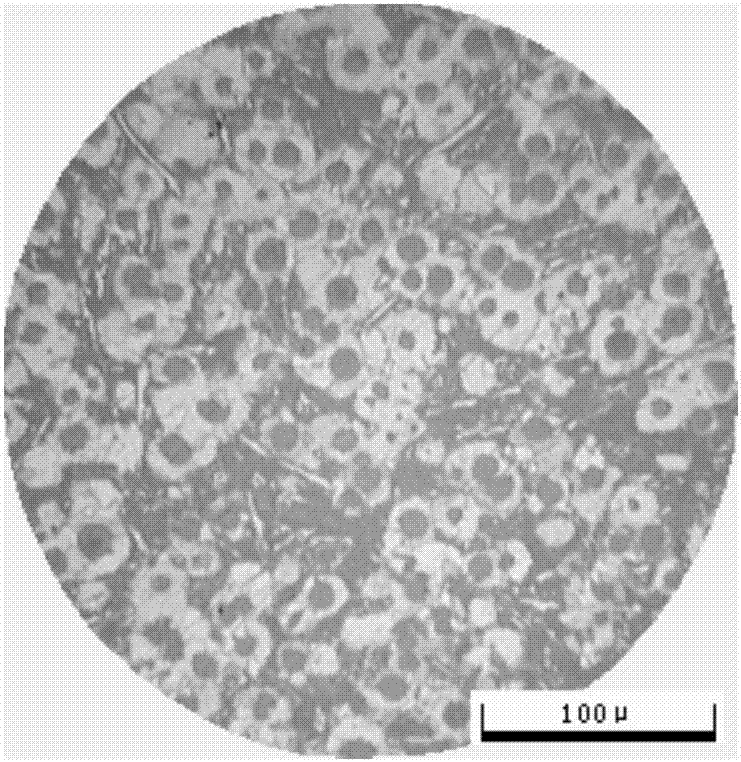

Image

Examples

specific Embodiment approach 1

[0026] Specific implementation method 1: This embodiment is a low-temperature impact-resistant CADI ductile iron at minus 40°C. The carbon mass fraction in the minus-40°C low-temperature impact CADI ductile iron is 3.5% to 3.7%, and the silicon mass fraction is 2.70% to 2.90%. , the mass fraction of manganese is less than 0.20%, the mass fraction of chromium is 0.6% to 0.7%, the mass fraction of phosphorus is less than 0.035%, and the mass fraction of copper is 0.8% to 1.0%. The unnotched impact value at -40°C is 25J to 30J.

specific Embodiment approach 2

[0027] Specific implementation mode 2: This implementation mode is a preparation method of CADI ductile iron with low temperature impact resistance at minus 40°C, which is specifically completed according to the following steps:

[0028] 1. Prepare raw materials: Weigh 70 parts of nodular pig iron Q10, 10 parts of low-manganese scrap steel, 20 parts of recycled materials, 0.9-1.0 parts of ferrochrome, 0.8-1.0 parts of copper plate, 1.3-1.36 parts of nodularizer, 0.19-0.23 parts of ultra-fine SiC powder, 0.35-0.40 parts of desulfurizer, 0.9-1.0 parts of ferrosilicon inoculant, 1.0 part of low-manganese crushed steel and 0.08-0.12 parts of silicon-barium inoculant;

[0029] 2. Melting: Add 70 parts of nodular pig iron Q10, 10 parts of low-manganese scrap steel and 20 parts of returned materials weighed in step 1 into the melting furnace, and raise the temperature to 1510 ° C ~ 1530 ° C, and melt at a temperature of 1510 ° C ~ 1530 ° C until it is completely melted, then add 0.9 ...

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the particle size of the ultrafine SiC powder described in step one is less than 40nm, and the mass fraction of SiC in the ultrafine SiC powder is 99.0 %. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com