A nitrogen-increasing and manganese-increasing method for high-strength steel production

A technology of high-strength steel and manganese nitride cladding, which is applied in the field of iron and steel metallurgy and steelmaking, can solve problems such as insufficient nitrogen addition, and achieve the effects of increased yield, excellent cold bending performance, and improved impact value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

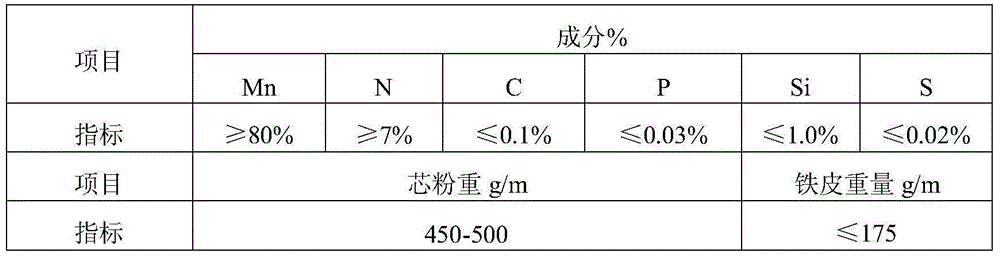

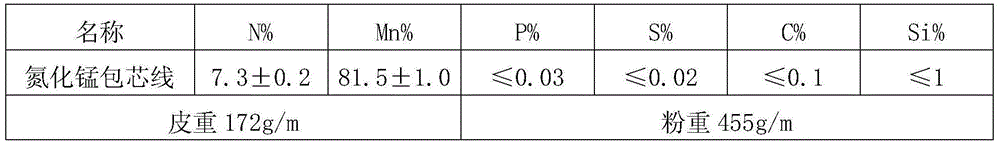

Image

Examples

Embodiment 1

[0035] Example 1: S450J0 steel grade, 120-ton double blowing converter

[0036] S450J0 steel is produced by using molten iron pretreatment→top-bottom double blowing converter smelting→LF furnace refining→continuous casting process, wherein nitrogen and manganese are increased by the method of the present invention, and other operations can be performed according to the prior art. It includes the following steps:

[0037] a. Using pretreated molten iron, various alloys should be baked and dried before use;

[0038] b. Control target of converter end point: [C]≥0.08%, [P]≤0.025%, T≥1650℃; adopt slag blocking for tapping, use silicon manganese, ferrosilicon and vanadium nitrogen for alloying, and melt manganese in molten steel during alloying The content is controlled at the lower limit of the composition (the lower limit of the manganese composition of S450J0 steel is 1.30%), the silicon calcium barium is finally deoxidized, the addition amount is 2.0kg / t steel, and the lime bl...

Embodiment 2

[0043] Example 2: Q550D, 120-ton double blowing converter

[0044] The Q550D steel produced by using molten iron pretreatment→top-bottom double blowing converter smelting→LF furnace refining→continuous casting process, wherein the method of the present invention is used to increase nitrogen and manganese, and other operations can be performed according to the prior art. Proceed as follows:

[0045] a. Using pretreated molten iron, various alloys should be baked and dried before use;

[0046] b. Control target of converter end point: [C]≥0.06%, [P]≤0.020%, T≥1640℃; adopt slag blocking for tapping, use silicon manganese, ferroniobium, and ferrochrome alloying, and finally deoxidize aluminum manganese and ferromanganese, add The amount of steel is 3.5kg / t, and 600kg of white ash blocks are added. During alloying, the manganese content of molten steel is controlled at the lower limit of composition (the lower limit of manganese for Q550D is 1.20%).

[0047] c. After the ladle e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com