Food package sealing performance detection device

A technology for tightness detection and food packaging, which is used in fluid tightness testing, measuring devices, and liquid tightness measurement using liquid/vacuum degree. The effect of sex inspection and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

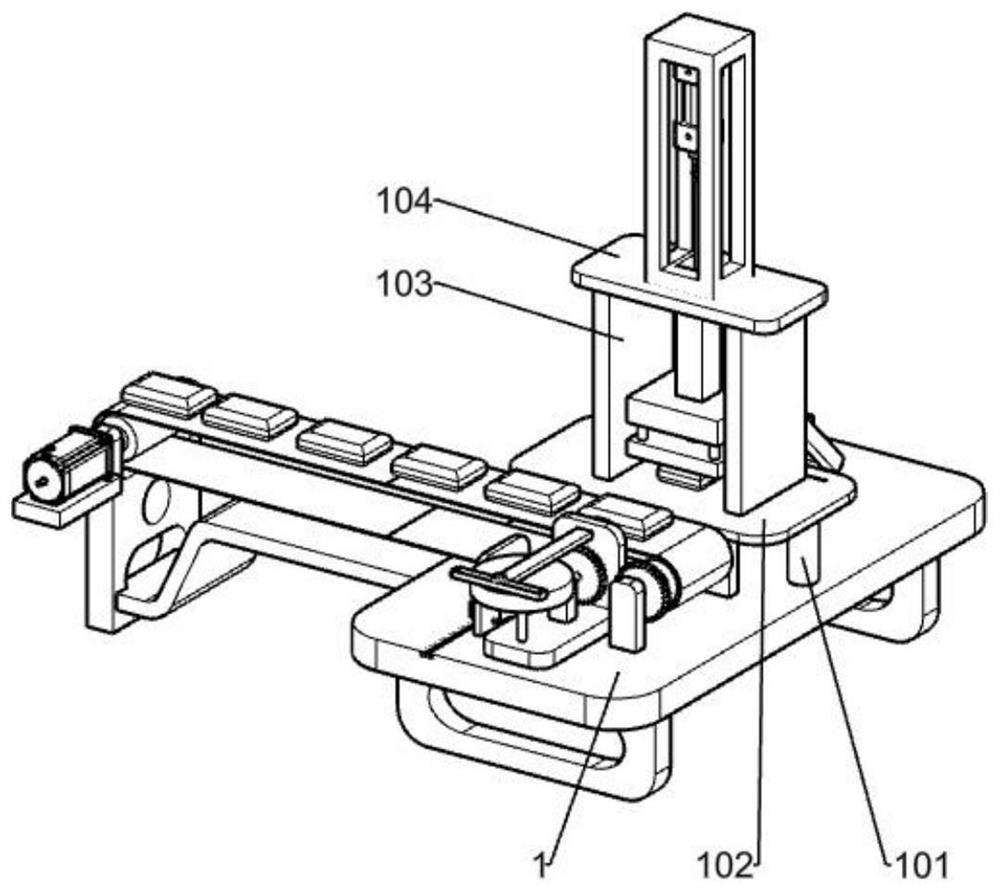

[0027]Food packaging sealing detection device, such asFigure 1-7 As shown, there is a base 1, a first strut 101, a sheet 102, a first vertical bracket 103, a top bracket 104, a pressure assembly 2, and a push mechanism 4, and a base 1 fixing two first pillars 101, The plate 102 is fixed to the first pillar 101, and two first vertical brackets 103 are fixed to the sealing plate 102, and the first vertical bracket 103 is provided with a upper bracket 104, and the pressure assembly 2 is fixed to the upper bracket 104, and The board 102 is at the pressure assembly 2, and the introduction mechanism 4 is fixed to the base 1; when operating, the introduction mechanism 4 pushes the pumping packaging food that needs to be detected to the reticle 102, and the article is between the two first vertical brackets 103. The pressure assembly 2 performs pressure detection on the food that needs to be detected, in which the closedness of the inflatable package is realized.

Embodiment 2

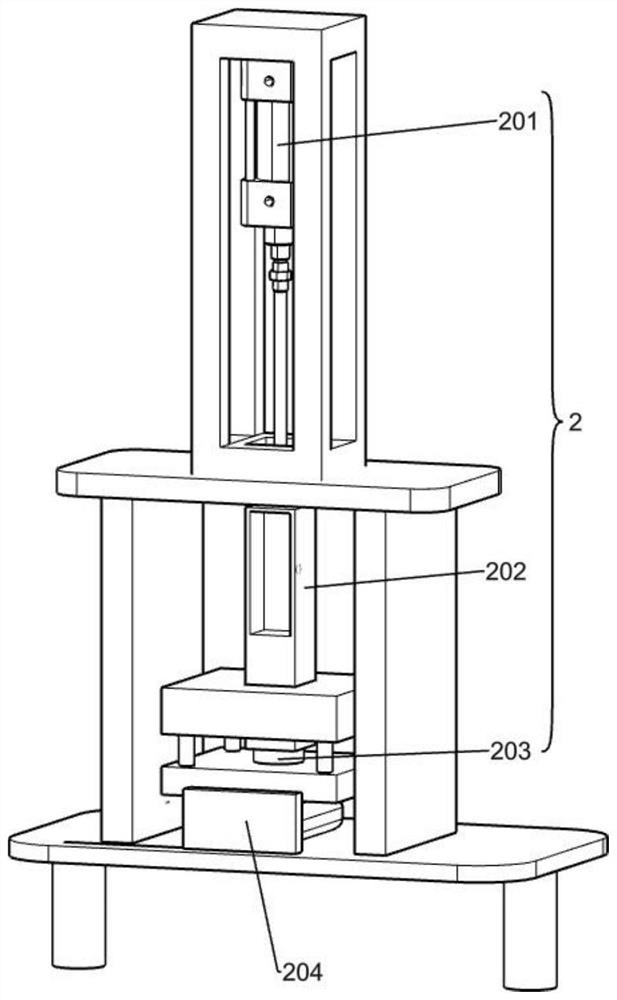

[0029]On the basis of Example 1, such asfigure 2 As shown, the pressure assembly 2 includes a cylinder 201, a second strut 202, and a pressure detector 203, and the cylinder 201 is fixed to the upper bracket 104, and the retractable rod of the cylinder 201 passes through the bottom plate of the upper bracket 104, and the second pillar 202. The upper end is fixed, and the lower end of the second pillar 202 is fixed to the pressure detector 203; manually open the cylinder 201, the telescopic rod of the cylinder 201 projects, drive the second strut 202 and the pressure detector 203 to move down, when the pressure detector 203 When the sample is contacted, the pressure detector 203 detects the sample.

Embodiment 3

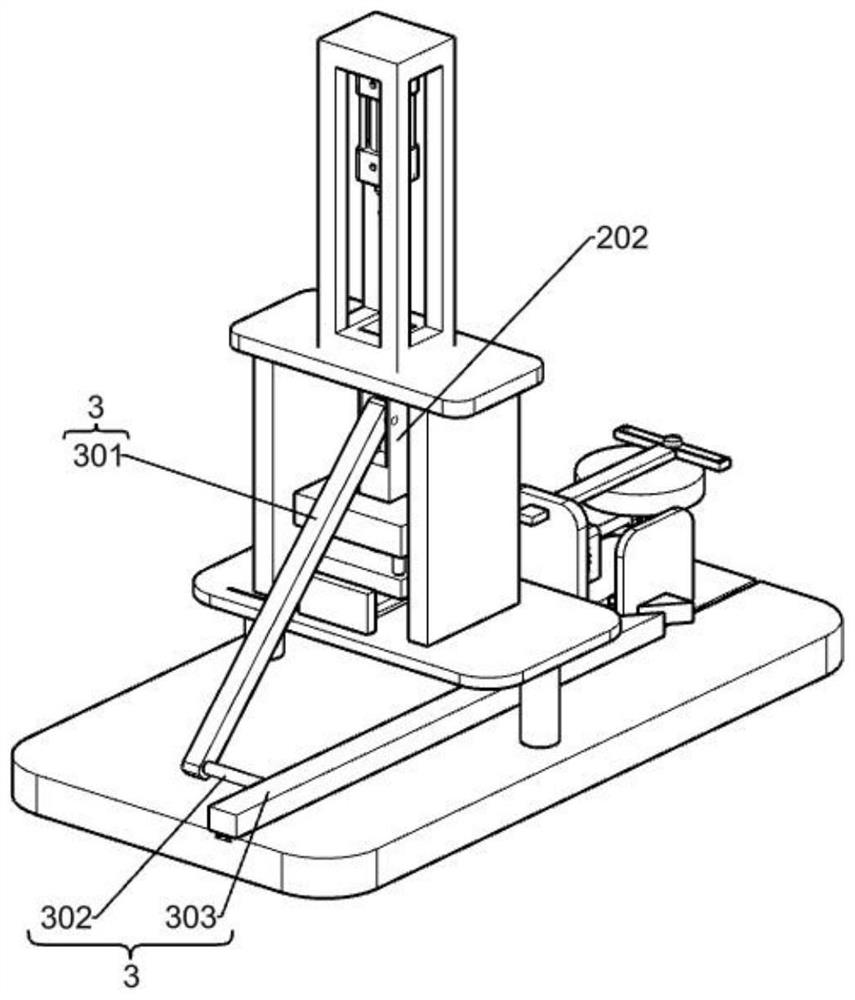

[0031]On the basis of Example 2, such asFigure 3-7As shown, the moving mechanism 3 includes a connecting rod 301, a first rotating shaft 302, a slider 303, a push block 304, a second vertical bracket 305, a tension spring 306, and a pull plate 307, and the upper end of the connecting rod 30 and the second pillar 202 hinged. The lower end of the connecting rod 301 is hinged from the first rotating shaft 302, and the first rotating shaft 302 is fixed to the rear end of the slider 303, the sliding rod 303 is slidably connected to the retaining plate 102, and the second vertical bracket 305 is fixed to the base 1, push the block. 304 sliding in the second vertical bracket 305, the tensile spring 306 has two, the pull plate 307 is fixed to the push block 304, and both ends of the tensile spring 306 are fixed to the second vertical bracket 305 and the pull plate 307. The front end of the slider 303 is inclined, the left end of the push block 304 is inclined, and the slider 303 is inoperat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap