Pre-subpackaging injector

A syringe and pre-packaging technology, which is applied in the directions of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of not being able to identify whether the syringe has been used by a straight tube, affecting work efficiency, and troublesome injection operations, and achieving simple structure and improved performance. The effect of safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

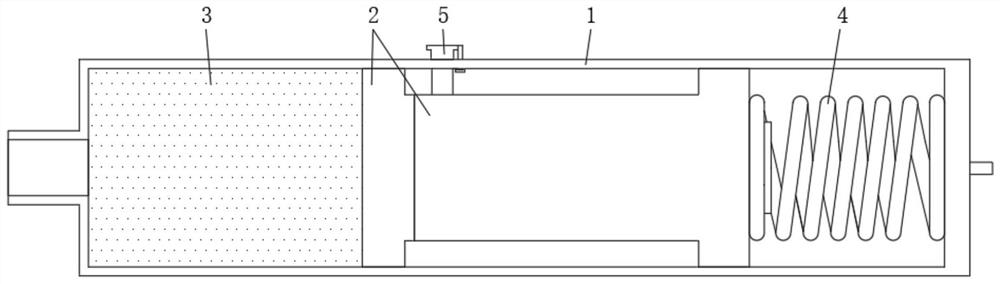

[0031] as attached figure 1 As shown, a pre-packed syringe provided for an embodiment of the present invention includes a syringe 1 and a piston 2, and the pre-packed syringe also includes:

[0032] An elastic member 4 for pushing the piston 2 to move in the syringe 1, so that the liquid medicine 3 in the syringe 1 is injected; and

[0033] When the elastic member 4 is compressed, the position-limiting assembly 5 that limits the position of the piston 2 .

[0034] Specifically, the syringe 1 is a syringe 1 with a closed bottom, the elastic member 4 is located between the piston 2 and the bottom of the syringe 1 , and the dispensing liquid 3 is located between the piston 2 and the injection end of the syringe 1 . The principle of use of the pre-packed syringe of this embodiment is as follows: by adjusting the limit assembly 5, the piston 2 is in a movable state from the limit of the limit assembly 5. At this time, the compressed elastic member 4 rebounds and pushes the piston....

Embodiment 2

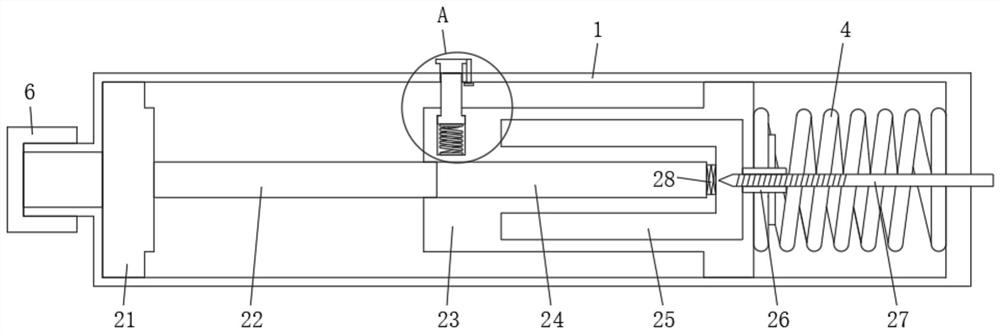

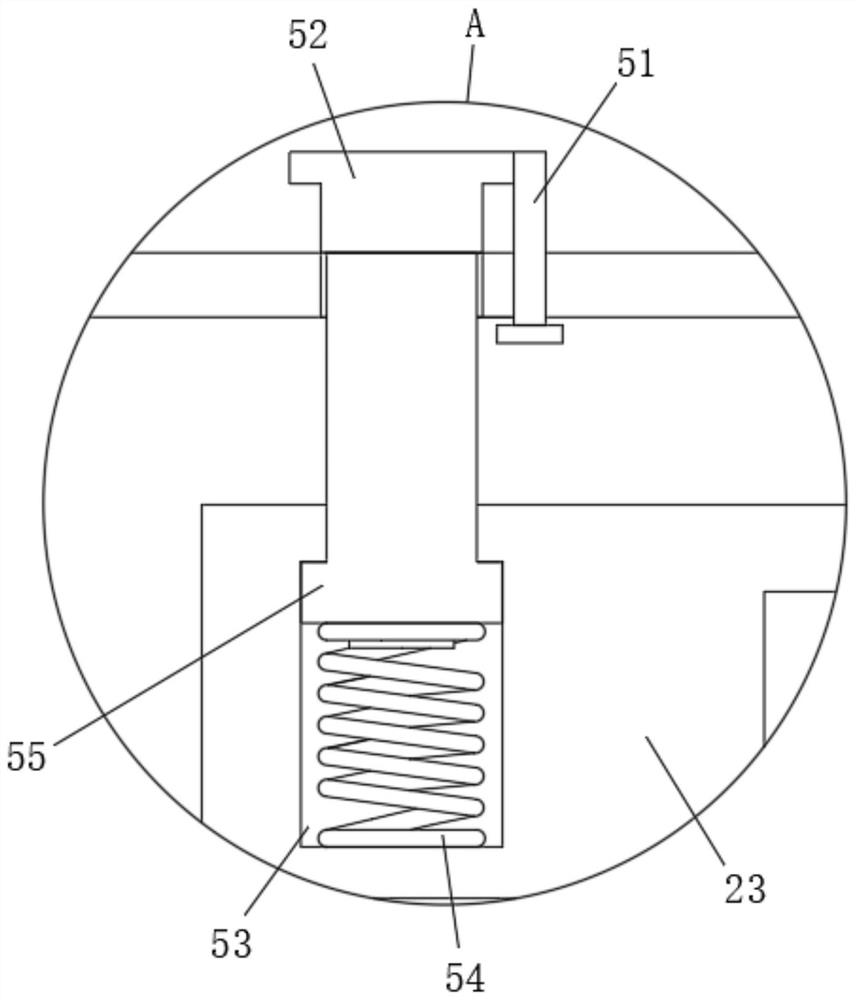

[0046] as attached figure 2 As shown, a pre-packed syringe provided by an embodiment of the present invention, on the basis of the pre-packed syringe in Example 1, the pre-packed syringe also has the following technical characteristics:

[0047] The piston 2 includes:

[0048] The first piston block 21; the first piston block 23 is provided with a piston rod 22;

[0049] The second piston block 23; the second piston block 23 is provided with a piston groove 24 matching the piston rod 22; the second piston block 23 is provided with a negative pressure chamber 25;

[0050] The prepacked syringe also includes a conduction assembly for conducting the negative pressure chamber 25 with the piston groove 25 .

[0051] Specifically, the pre-packed syringe technology provided in Example 1 realizes the automatic injection of the subpackaged medicinal solution 3, while the deposit of the subpackaged medicinal solution 3 needs to be completed with corresponding professional equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com