Precision filter for chemical production and processing

A precision filter and chemical production technology, applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of low filtration efficiency, high cost, complex structure, etc., and achieve simple structure and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

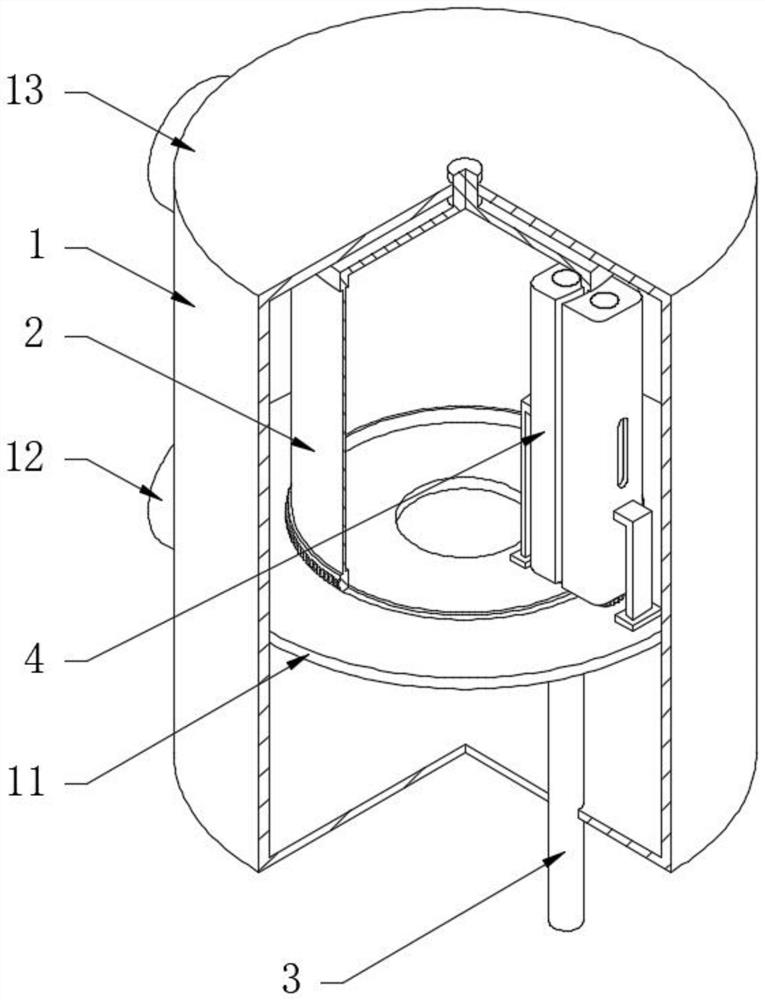

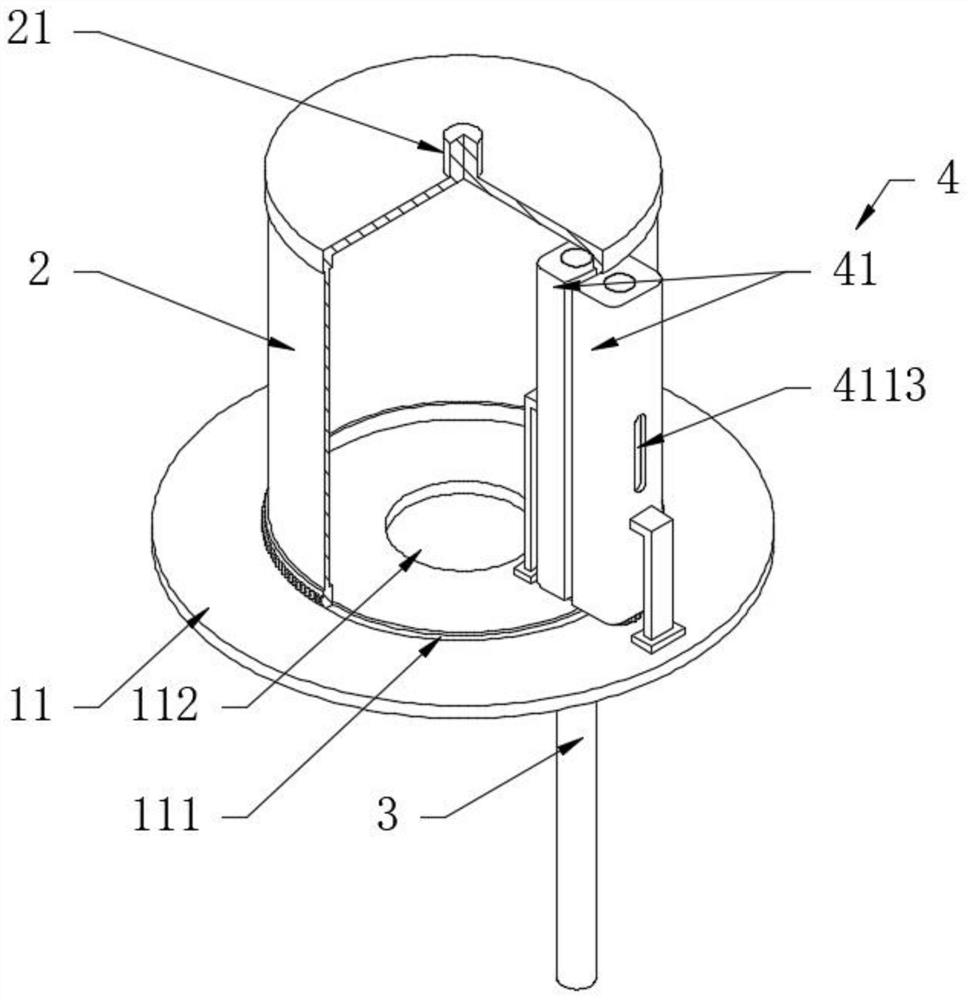

[0031] see Figure 1-6 , a precision filter for chemical production and processing, including an outer cylinder 1, a filter cartridge 2 and a sewage pipe 3, the filter cartridge 2 is arranged in the outer cylinder 1, the top of the filter cartridge 2 is a blind end and the bottom is an open end, the filter cartridge The top of the filter cartridge 2 is fixedly provided with a drive shaft 21 that is rotatably connected to the top of the outer cylinder 1, and the outer cylinder 1 is fixedly provided with a partition plate 11 that is rotatably matched with the bottom of the filter cartridge 2, and the partition plate 11 divides the inner cavity of the outer cylinder 1 into a raw liquid chamber And the clean chamber, specifically, the upper end surface of the partition plate 11 is provided with an annular groove 111 that is rotatably connected to the bottom of the filter cartridge 2, and the outside of the outer cylinder 1 is fixedly provided with a feed pipe 12 and a discharge pip...

Embodiment 2

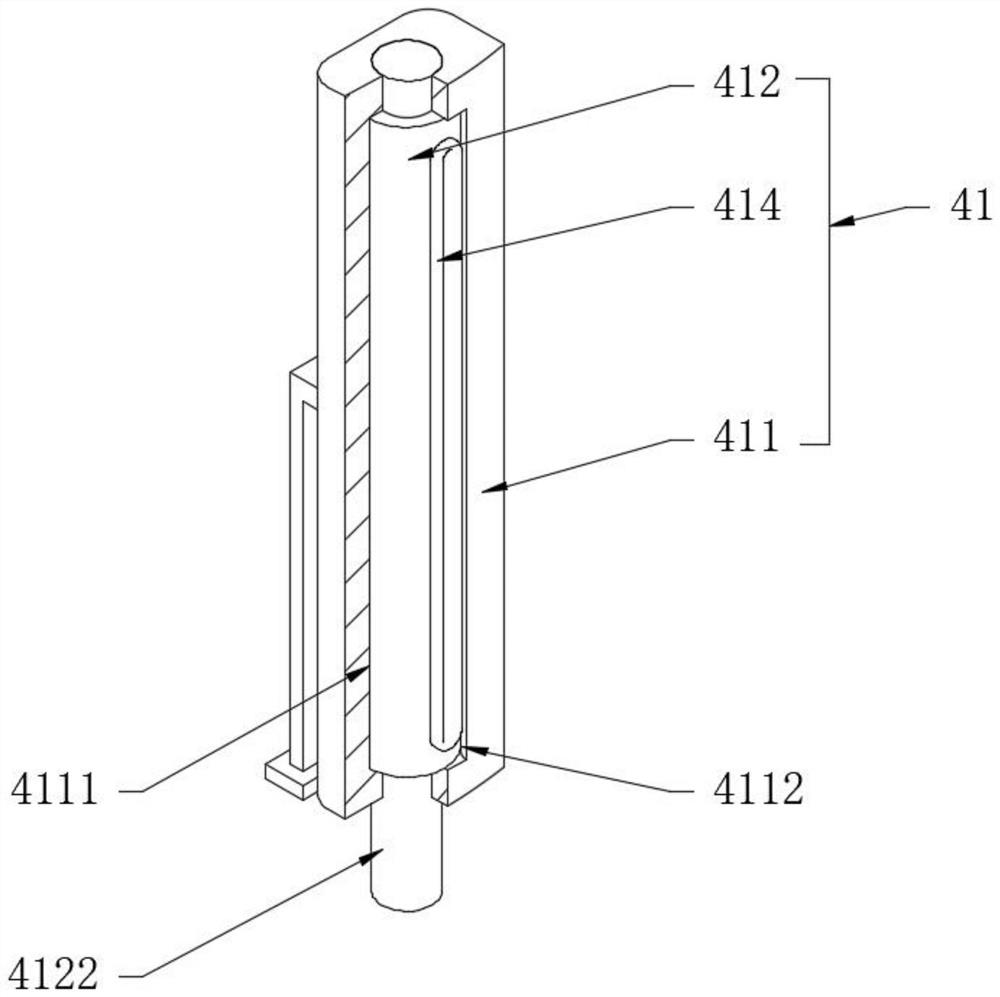

[0033] see Figure 5The difference from Embodiment 1 is that the sewage guiding combination 41 also includes a gear one 415 and a gear two 416. The gear one 415 is located under the partition plate 11 and is respectively fixedly sleeved on two transmission shafts 4122. The two gears one 415 Engagement, the second gear 416 is located above the partition plate 11 and is fixedly sleeved on the transmission shaft 4122 located outside the filter cartridge 2. The second gear 416 meshes with the outer wall of the filter cartridge 2 and is close to the bottom, so that the filter cartridge 2 rotates It can drive the second gear 416 to rotate, and the second gear 416 drives the other transmission shaft 4122 to rotate through the transition connection of the two first gears 415 to realize the synchronous operation of the two rotary columns 412. The structure is simple and the cost is low.

Embodiment 3

[0035] see figure 2 and Figure 5 The difference from Example 1 is that the other side of the fixed cuboid 411 outside the filter cartridge 2 is provided with a feed hole 4113, and the bottom of the corresponding transmission shaft 4122 at the bottom of the fixed cuboid 411 is screwed with a plug 5, and the feed hole 4113 is located in the clean chamber, and the plug 5 seals the transmission shaft 4122, thus no need to connect the external air supply pipeline. Due to the certain pressure in the clean chamber, a small amount of clean liquid is in the two waist-shaped holes inside and outside the filter cartridge 2 When 4121 is connected, it passes through the filter cartridge 2 through the feed hole 4113, then enters the waist-shaped hole 4121 located in the filter cartridge 2, and then is discharged through the sewage pipe 3. During this process, the impurities and dirt on the inner wall of the filter cartridge 2 are removed. Clean liquid reverse osmosis mixes and separates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com