Smart plug remover

A blockage remover, intelligent technology, applied in the direction of electrode cleaning, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problem of automatic detection and removal of nozzle blockage, inability to clean blockage conveniently and quickly, and inability to detect blockage in real time and other issues, to achieve the effect of zero error detection, convenient procurement, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

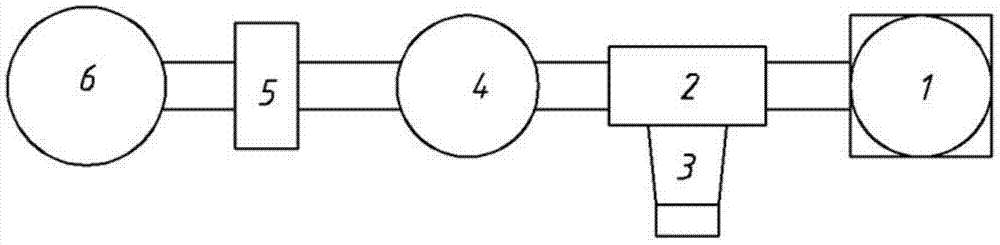

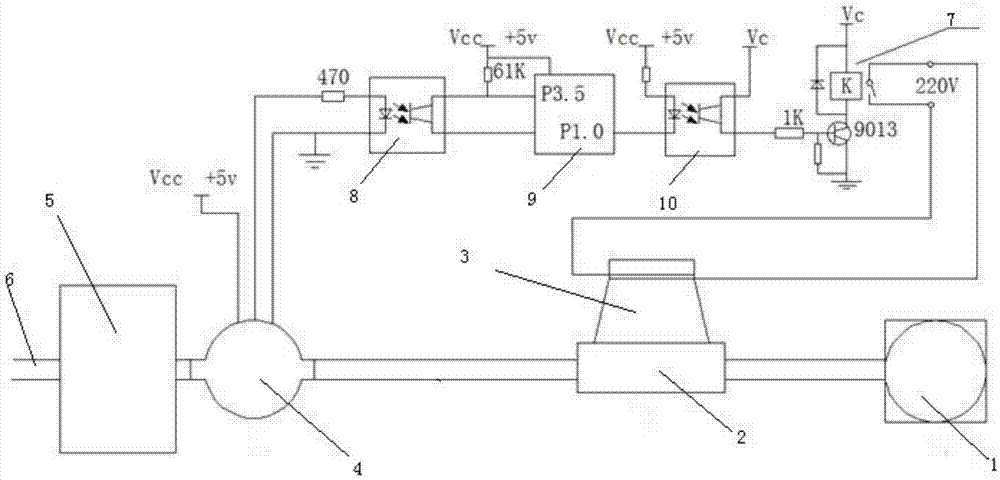

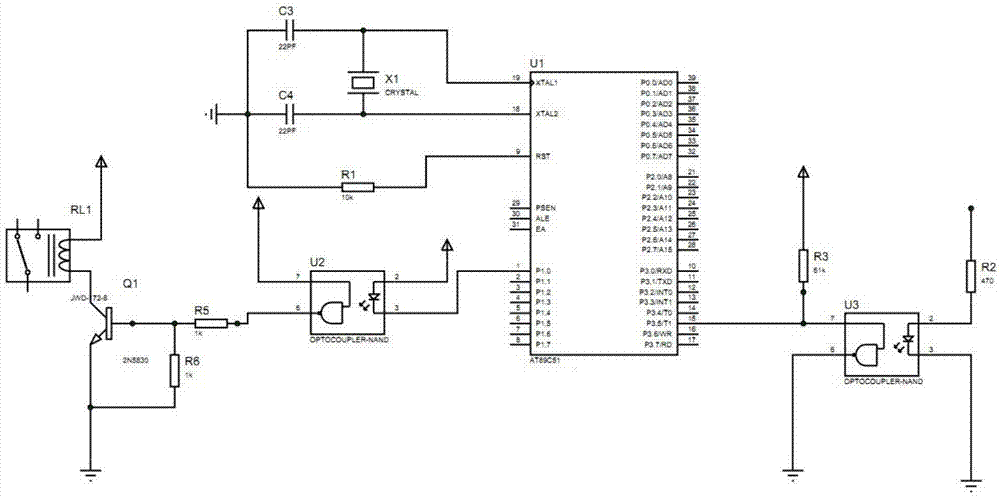

[0016] The present invention provides an intelligent blockage remover. For the structural and principle block diagram, please refer to figure 1 . For a structural diagram of an embodiment of the present invention, see figure 2 . The device comprises a settling box 5, a three-way interface 2, a Hall flowmeter 4, a first photoelectric coupling circuit 8, a second photoelectric coupling circuit 10, a single-chip microcomputer 9, a relay 7 and an ultrasonic vibrator 3; One interface is connected to the inlet of the spray nozzle 1 of the wet electrostatic precipitator, the second interface of the three-way interface 2 is connected to the Hall flowmeter 4, and the third interface of the three-way interface 2 is connected to the ultrasonic vibrator 3; After the Hall flowmeter 4 is installed in the outlet pipe of the settling tank 5, the Hall flowmeter 4 is connected with the input port of the single-chip microcomputer 9 through the first photoelectric coupling circuit 8, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com