Jaw crusher for garbage disposal and using method

A jaw crusher and garbage treatment technology, applied in grain treatment, chemical instruments and methods, magnetic separation, etc., can solve the problems of crusher impact, iron choking, shortened service life, etc., and achieve the effect of enhanced iron removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

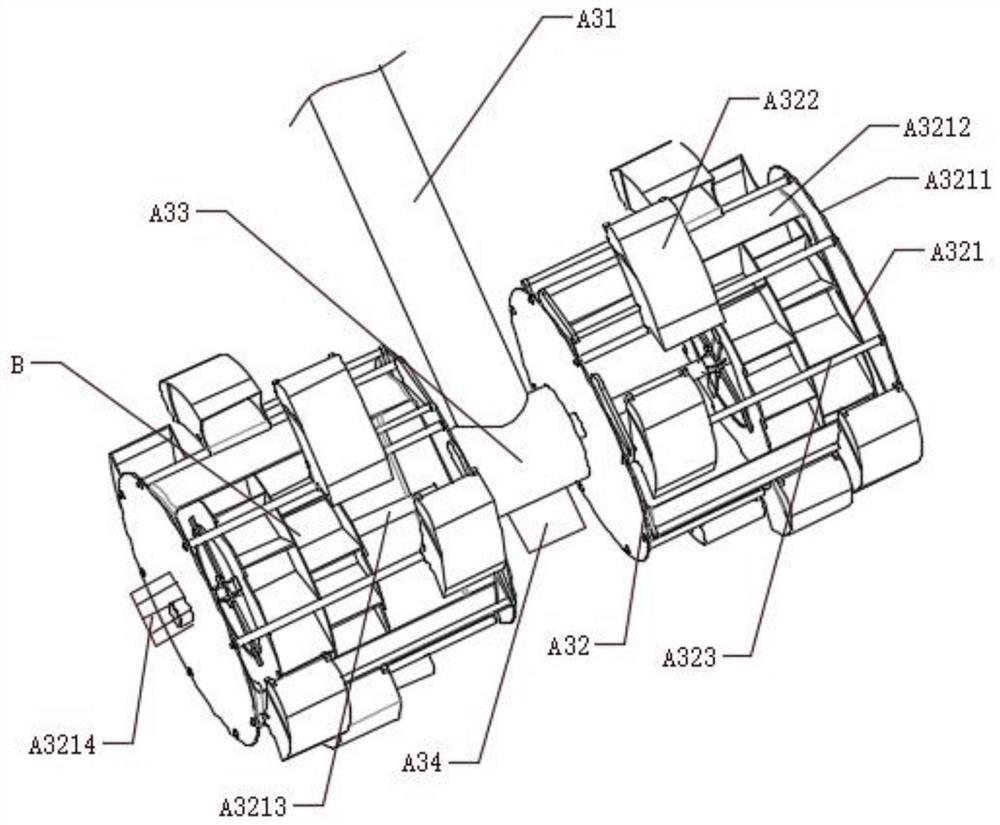

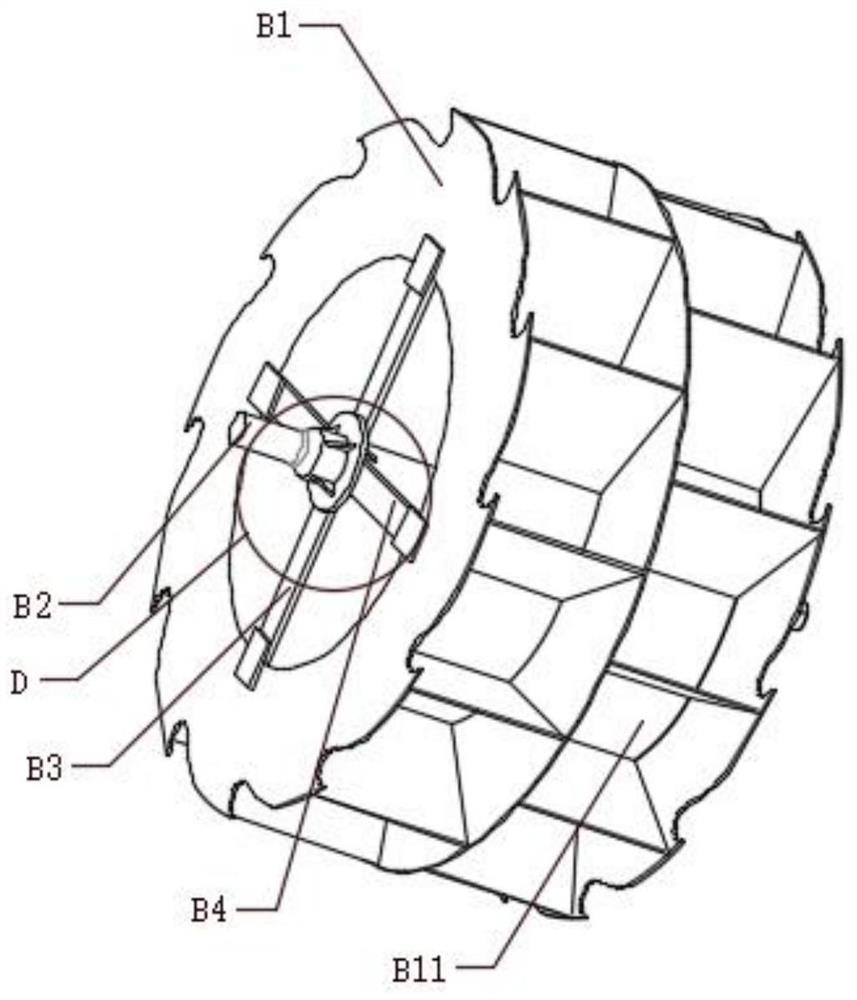

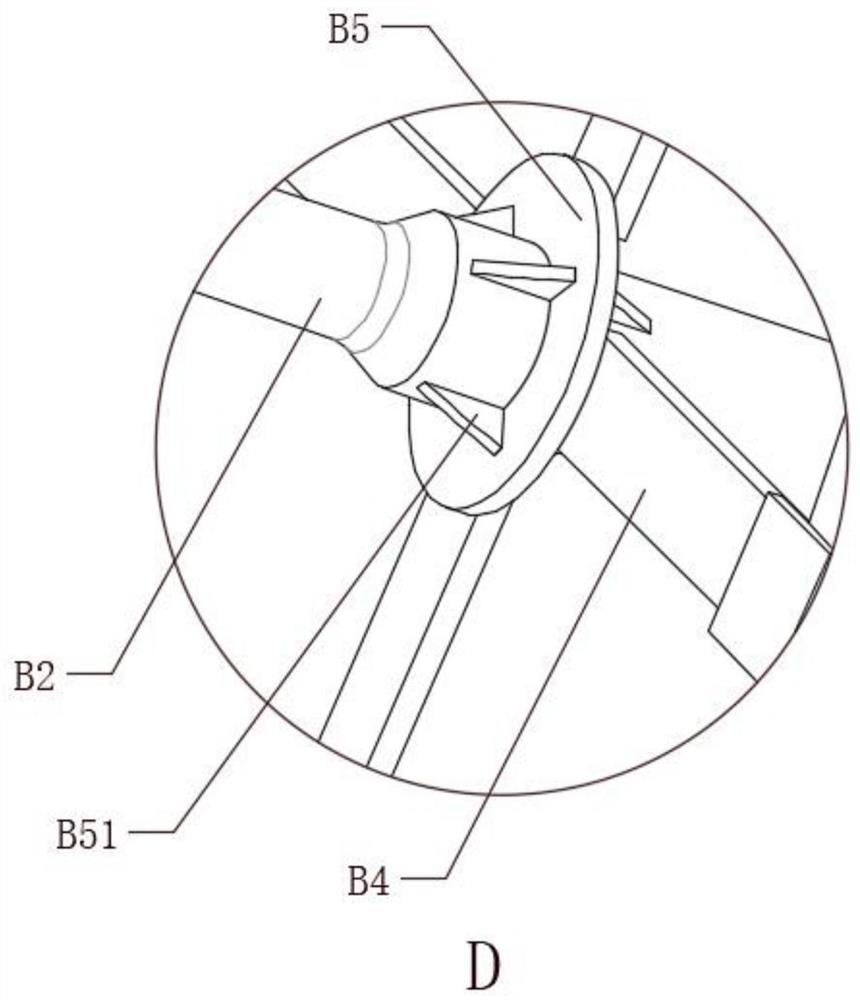

[0052] Such as Figure 1-10 As shown, a jaw crusher for garbage disposal of the present invention includes a jaw crusher body 1, an iron removal device A, and the iron removal device A is placed on the upper part of the jaw crusher body 1, and the iron removal device A The bottom is connected to the upper end of the feed port 10 of the jaw crusher body 1. The iron removal device A includes a rocker arm A1, a lifting mechanism A2 and an iron-absorbing unit A3. The upper end of the rocking arm A1 is connected to the outside of the lifting mechanism A2. Unit A3 is connected to the bottom end of the rocker arm A1, and the iron-absorbing unit A3 is placed in the V-shaped cavity formed between the fixed jaw plate and the movable jaw plate. The iron-absorbing unit A3 includes a hollow connecting arm A31 and two absorbing jaws. The iron part A32, the two iron-absorbing parts A32 are symmetrically connected to both sides of the bottom of the connecting arm A31, the top of the connecting ...

Embodiment 2

[0064] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a jaw crusher for garbage disposal of the present invention includes a jaw crusher body 1, an iron removal device A, and the iron removal device A is placed on the upper part of the jaw crusher body 1, and the iron removal device A The bottom is connected to the upper end of the feed port 10 of the jaw crusher body 1. The iron removal device A includes a rocker arm A1, a lifting mechanism A2 and an iron-absorbing unit A3. The upper end of the rocking arm A1 is connected to the outside of the lifting mechanism A2. Unit A3 is connected to the bottom end of the rocker arm A1, and the iron-absorbing unit A3 is placed in the V-shaped cavity formed between the fixed jaw plate and the movable jaw plate. The iron-absorbing unit A3 includes a hollow connecting arm A31 and two absorbing jaws. The iron part A32, the two iron-absorbing parts A32 are symmetrically connected to both si...

Embodiment 3

[0078] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a jaw crusher for garbage disposal of the present invention includes a jaw crusher body 1, an iron removal device A, and the iron removal device A is placed on the upper part of the jaw crusher body 1, and the iron removal device A The bottom is connected to the upper end of the feed port 10 of the jaw crusher body 1. The iron removal device A includes a rocker arm A1, a lifting mechanism A2 and an iron-absorbing unit A3. The upper end of the rocking arm A1 is connected to the outside of the lifting mechanism A2. Unit A3 is connected to the bottom end of the rocker arm A1, and the iron-absorbing unit A3 is placed in the V-shaped cavity formed between the fixed jaw plate and the movable jaw plate. The iron-absorbing unit A3 includes a hollow connecting arm A31 and two absorbing jaws. The iron part A32, the two iron-absorbing parts A32 are symmetrically connected to both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com