High-precision laser cleaning and cleaning quality online monitoring device and method

A laser cleaning, high-precision technology, applied in measuring devices, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of small environmental impact and high measurement accuracy, and achieve the effect of complete and accurate detection and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

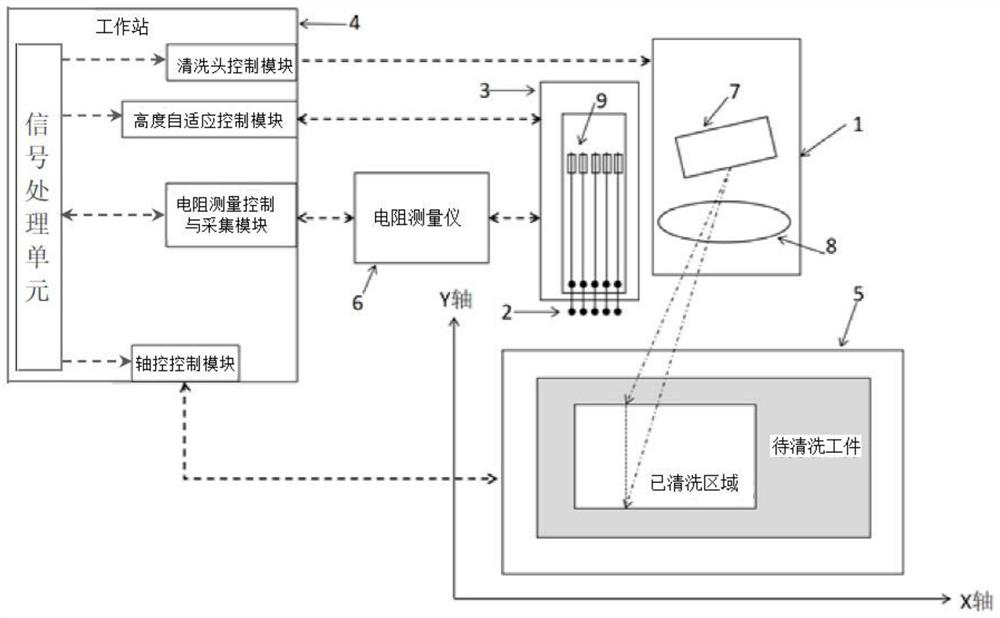

[0044] refer to figure 1 , the present invention provides a high-precision laser cleaning and cleaning quality online monitoring device, which is characterized in that it includes an XY axis platform, a laser cleaning head, a resistance probe array, a resistance measuring instrument, a probe height self-adaptive adjustment unit and a workstation,

[0045] The laser cleaning head includes a laser head, a vibrating mirror, and a field mirror. During laser cleaning, the laser beam is emitted from the laser head, passes through the vibrating mirror and the field mirror in turn, and irradiates the surface of the cleaning workpiece placed on the XY axis platform. The XY-axis platform moves to clean the surface of the workpiece to complete the surface cleaning of the entire workpiece;

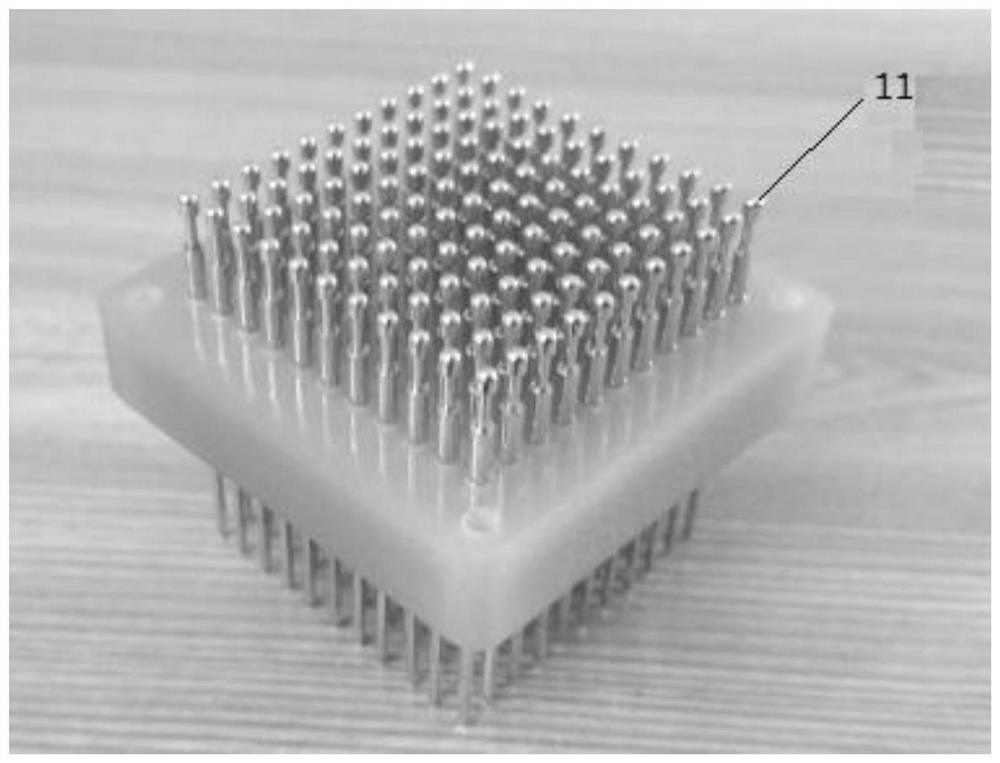

[0046] The resistance probe array includes a probe array of a specific shape formed by a plurality of resistance measuring probes, which is one of square, rectangular or circular probe arrays; the res...

example 2

[0064] The difference between this embodiment and Example 1 is that the resistance measurement accuracy measured by the resistance meter is 0.001 milliohms, which is relatively high, and can greatly reduce the impact of the laser cleaning laser environment such as light and noise on the monitoring system. For different environments More adaptable.

[0065] In this embodiment, a square resistance probe array of 5 cm*5 cm is selected.

[0066] The rest of the content is the same as Example 1.

example 3

[0068] The difference between this embodiment and Example 1 is that the workstation uses the axis control control module and the probe height self-adaptive adjustment control module to collect and clean the workpiece surface position information (coordinates) and the corresponding probe height distribution values in real time. The height distribution value is filtered by a first-order filter to reduce measurement errors.

[0069] In this embodiment, a square resistance probe array of 10 cm*10 cm is selected. The resistance measurement accuracy measured by the resistance meter is specifically selected as 0.001 milliohms.

[0070] The rest of the content is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com