Control system for oil product viscosity detection equipment

A control system and detection equipment technology, applied in the field of control systems, can solve the problems of oil heating and heat preservation, complex detection procedures, and bulky equipment, and achieve the effects of complete and accurate detection, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in combination with specific embodiments.

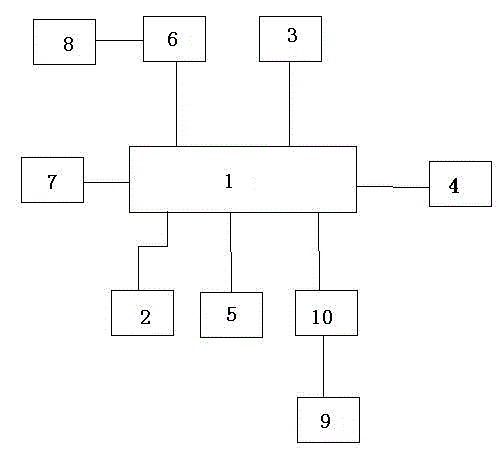

[0009] see figure 1 , a control system for oil viscosity detection equipment, the control system includes a central controller 1, a power supply 2, a heating system 3, a magnetic stirring system 4, a cleaning system 5, a driver 6, a locking system 7, a lifting system 8, Sensor 9 and CAN bus module 10, described central controller 1 is respectively connected with heating system 3, magnetic stirring system 4, latch system 7, cleaning system 5, CAN bus module 10, driver 6 and power supply 2, and described sensor 9 It is connected with the CAN bus module 10, and the lifting system 8 is connected with the driver 6.

[0010] The working principle of the present invention is: the central controller 1 starts the heating system 3 and starts the lifting system 8 at the same time. After the lifting device works, the sensor is invaded into the sample to start detection. During th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com