Method for eliminating ridge buckle of strip steel at finishing machine in production of thin and ultra-thin strip steel

A technology of skin pass and thin gauge, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as judgment deviation, strip accident, disrupted production rhythm, etc., to eliminate the problem of stiffening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

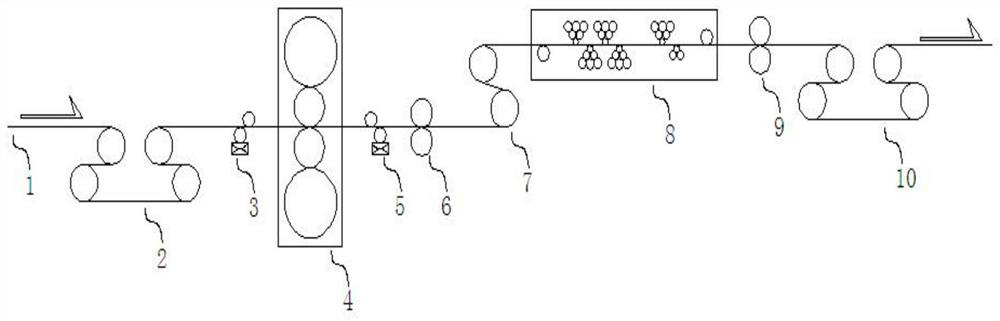

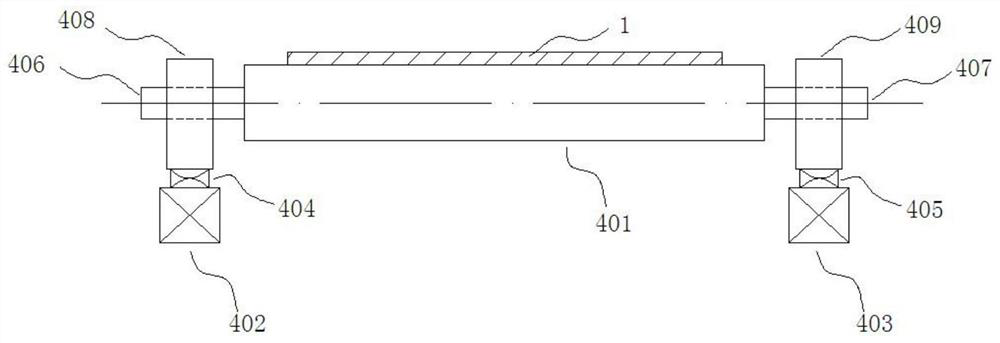

[0032] see figure 1As shown in the schematic diagram of the layout of the skin pass machine and the tension leveler of the production line, the tension of the skin pass machine 4 in the layout is composed of the No. 4 tension roller 2 and the No. The tension roller 7 is composed of the No. 6 tension roller 10. The strip steel 1 passes through the No. 4 tension roller 2, the skin pass machine entrance tension meter 3, the skin pass machine 4, the skin pass machine exit tension meter 5, and the skin pass machine exit. Dry roll 6, No. 5 tension roll 7, tension leveler 8, tension leveler exit squeeze dry roll 9, No. 6 tension roll 6 and then run backwards, forming the rolling force and elongation of the skin pass mill tension leveler process control equipment; the main testing equipment for the tension of the skin pass machine 4 is the skin pass machine inlet tension meter 3 and the skin pass machine exit tension meter 5, these arrangements are the equipment that the general produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com