Open type three-jaw self-centering chuck

A self-centering chuck and open-type technology, which is applied in the direction of the chuck, can solve the problems of small clamping force and thick product thickness, and achieve the effect of large clamping force, large stroke and zero error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

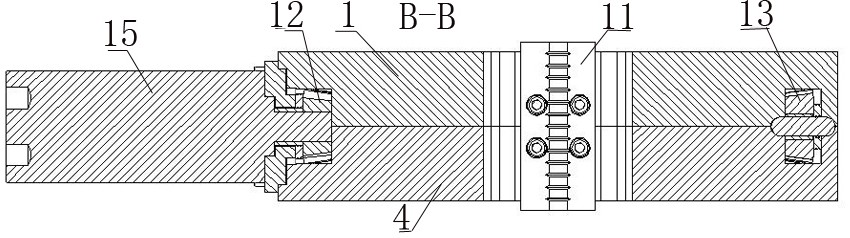

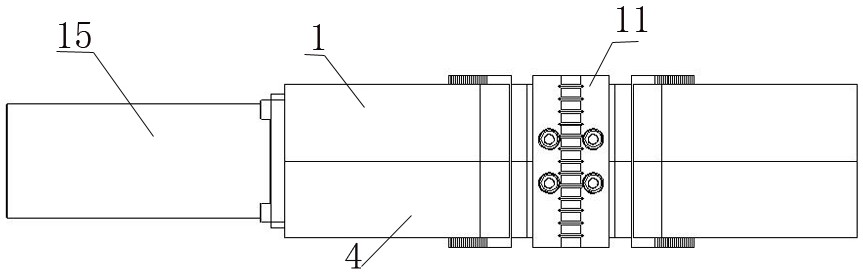

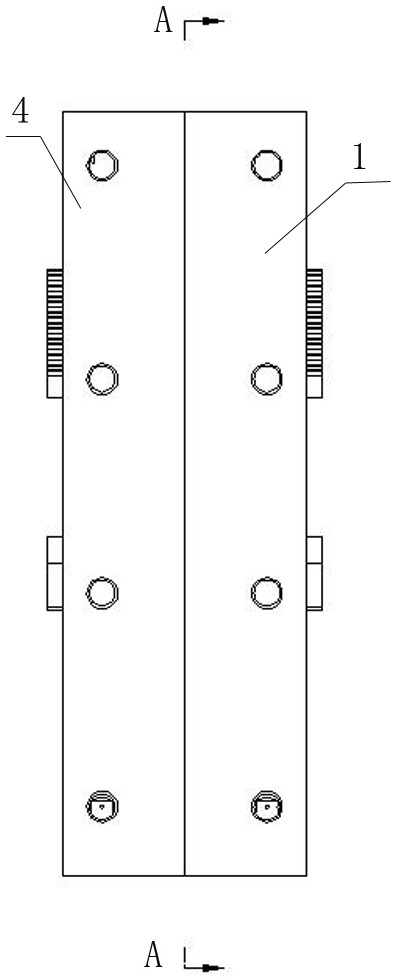

[0036] According to the present invention Figure 1-11 Indicated.

[0037] Embodiments of this product are:

[0038] An open trip self-center chuck, including a chip base 1 and a chuck upper base 4, the chip base 1 and the chuck upper base 4 together in which the intermediate is through hole 2, An annular groove 3 is provided on the disk surface of the chip base 1 and the chip 4 of the chuck, wherein the circular groove 3 and the through hole 2 are circular;

[0039] The first, second, third guide grooves 5, 6, 7, corresponding first, second, third guide grooves 5, 6, 7 are provided in the center direction of 120 ° interval at 120 ° interval. The front end of the first, second, third jaw drive screw assembly 8, 9, 10, first, second, and third jaws drive screw assemblies 8, 9, 10 is provided with a jaw assembly 11. First, second, the third jaw drive screw assembly 8, 9, 10 drive the jaw assembly 11 leads to the first, second, third guide grooves 5, 6, 7 to the center direction, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com