Automatic scaffold board production line

An automatic production line and scaffolding technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low production efficiency, complex structure, and liquid leakage, and achieve reasonable equipment arrangement, high production efficiency, and low cost of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

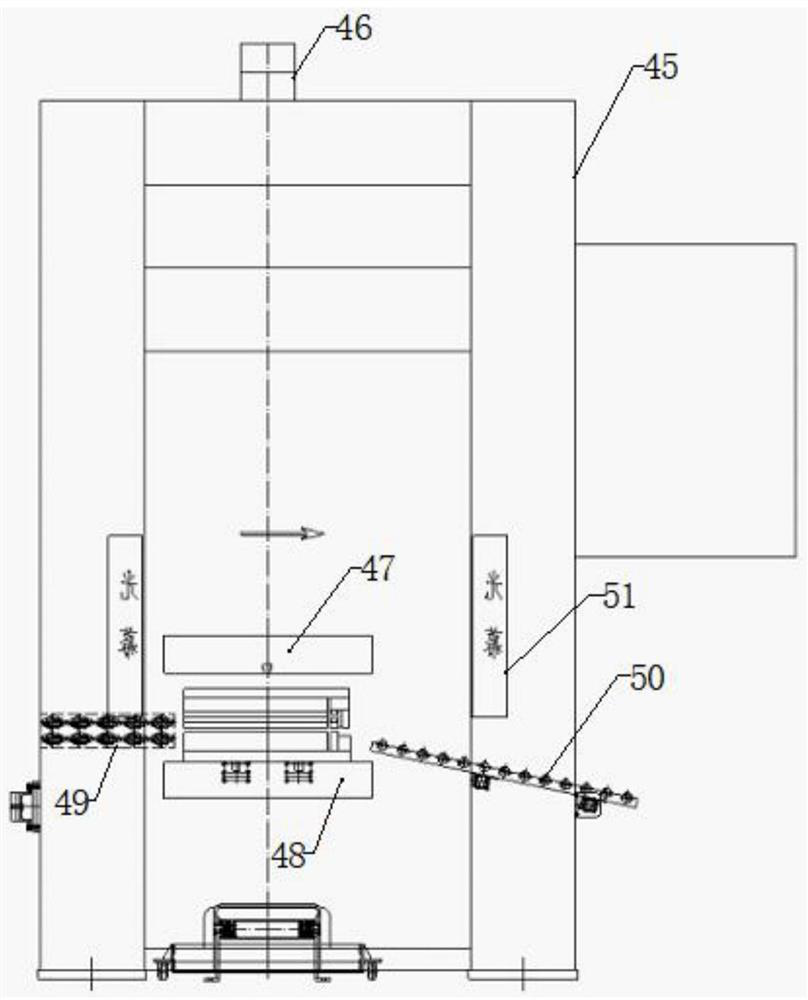

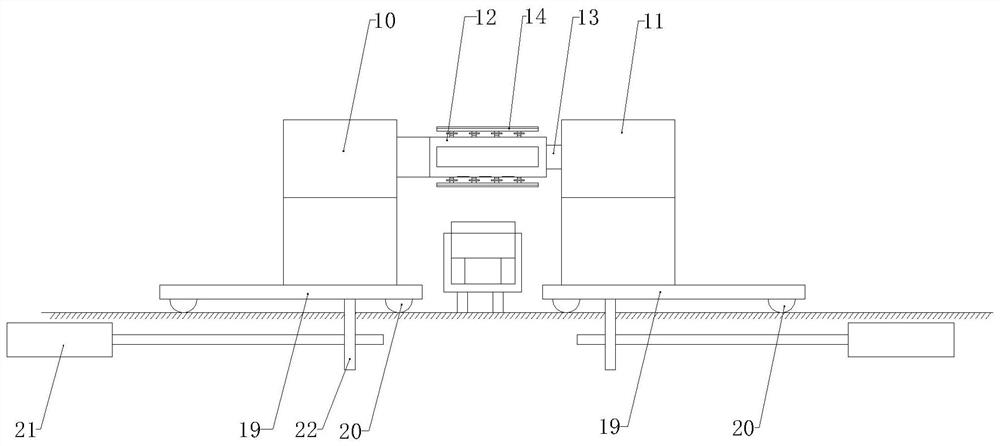

[0025] see Figure 1 to Figure 11 , an automatic production line for scaffolding in a preferred embodiment of the present invention, including an uncoiler 1, a leveling servo feeder 2, a punching machine 3, a roll forming machine 4, an online seam welding machine 5, a straightening machine 6, and a cutting machine 7 and conveying roller table 9, the input end of the leveling servo machine is located downstream of the output end of the uncoiler, the input end of the punching machine is located downstream of the output end of the leveling servo machine, and the input end of the roll forming machine is located downstream of the output end of the punching machine , the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com