Drilling equipment with steering function

A kind of drilling equipment and functional technology, applied in the field of drilling equipment with steering function, can solve the problems of reducing the scope of application and not having steering function, and achieve good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

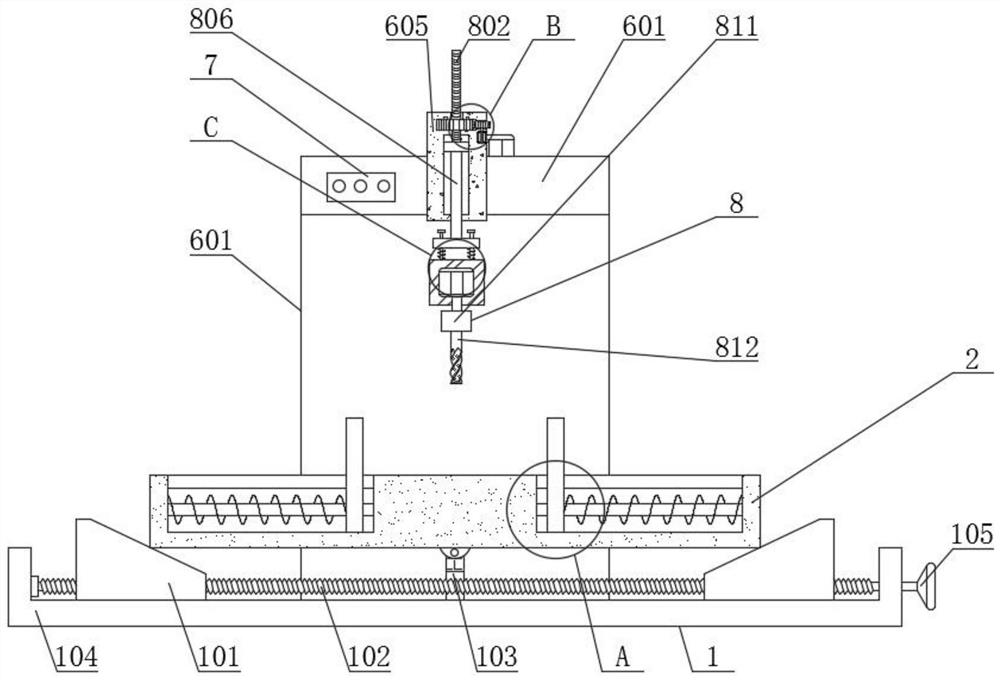

[0029] see Figure 1-7 , the present invention provides a technical solution:

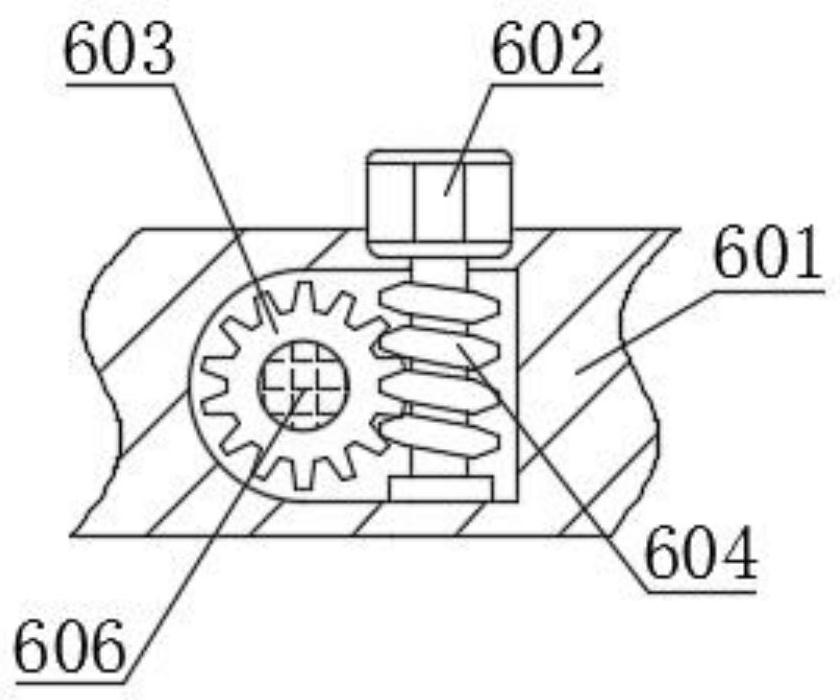

[0030] A drilling device with a steering function, comprising a support base 2, a splint 3 slidingly connected to the inside of the support base 2, a second limit rod 4 fixedly connected to the inside of the support base 2, and a first spring provided outside the second limit rod 4 5. The controller 7 and the drill-pipe steering mechanism 6, the drill-pipe steering mechanism 6 includes a side plate 601, the top inside of the side plate 601 is fixedly connected with a first motor 602, the end of the main shaft of the first motor 602 is fixedly connected with a worm 604, the worm The bottom of 604 is rotationally connected with the inner side of the bottom of side plate 601, and the inner side of the top of side plate 601 is rotationally connected with rotating shaft 606, and the outer side of rotating shaft 606 is fixedly connected with worm wheel 603, and the outer side of worm wheel 603 meshes wit...

Embodiment 2

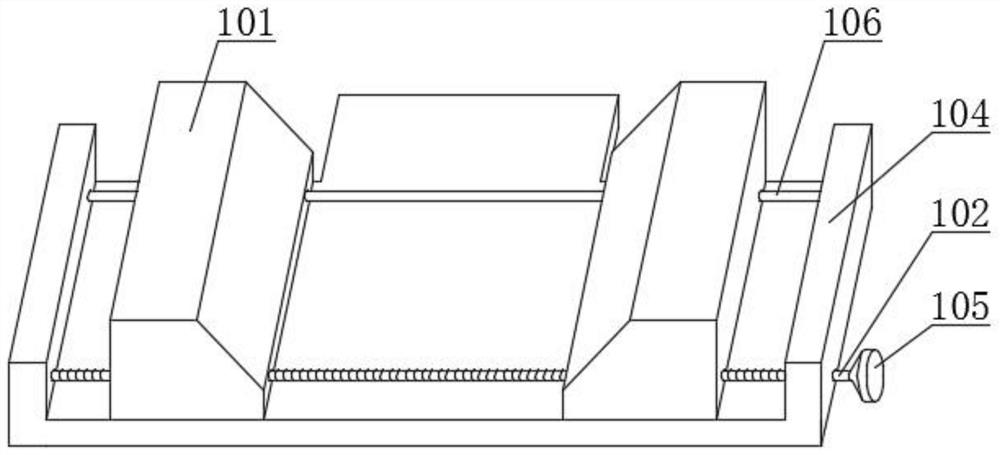

[0034] Embodiment 2: In this embodiment, the same places as in Embodiment 1 will not be repeated. The difference is that the present invention can also realize the steering of the drilling direction through the support steering mechanism 1, thereby being applicable to different drilling requirements. When working, the staff can first place the drilling object in the middle of the splint 3 on both sides of the support base 2, and the splint 3 will fix the drilling object under the action of the first spring 5. When turning, the staff turns the runner 105 , the runner 105 drives the first screw 102 to rotate, and during the rotation of the first screw 102, the first screw 102 will drive the wedge block 101 to move leftward or rightward, and the first stop rod 106 provided acts as a countermeasure against The movement direction of the wedge block 101 acts as a limiter. When the wedge blocks on both sides move to the left or right, the support seat 2 will be forced to tilt to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com