Storage structure of reconstituted tobacco of heating cigarette and online rolling system and method

A technology of reconstituted tobacco leaves and storage structure, which is applied in the field of heated cigarettes, can solve the problems of unavoidable moisture absorption and resurgence of reconstituted tobacco leaves, low production efficiency of cigarettes, and decreased tensile strength, so as to solve mutual sticking and expansion strength decline, and improve follow-up Handling performance, the effect of alleviating moisture absorption and regaining moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is a specific embodiment of the present invention, and the technical solutions of the present invention are further described with reference to the accompanying drawings, but the present invention is not limited to these embodiments.

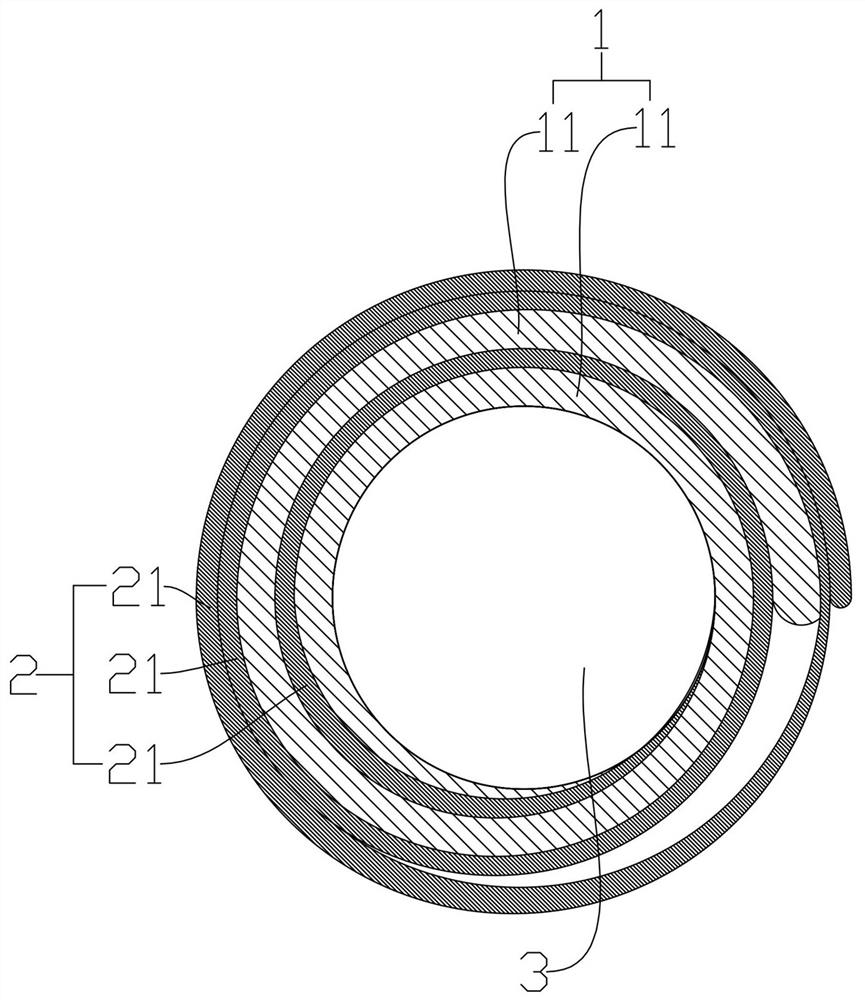

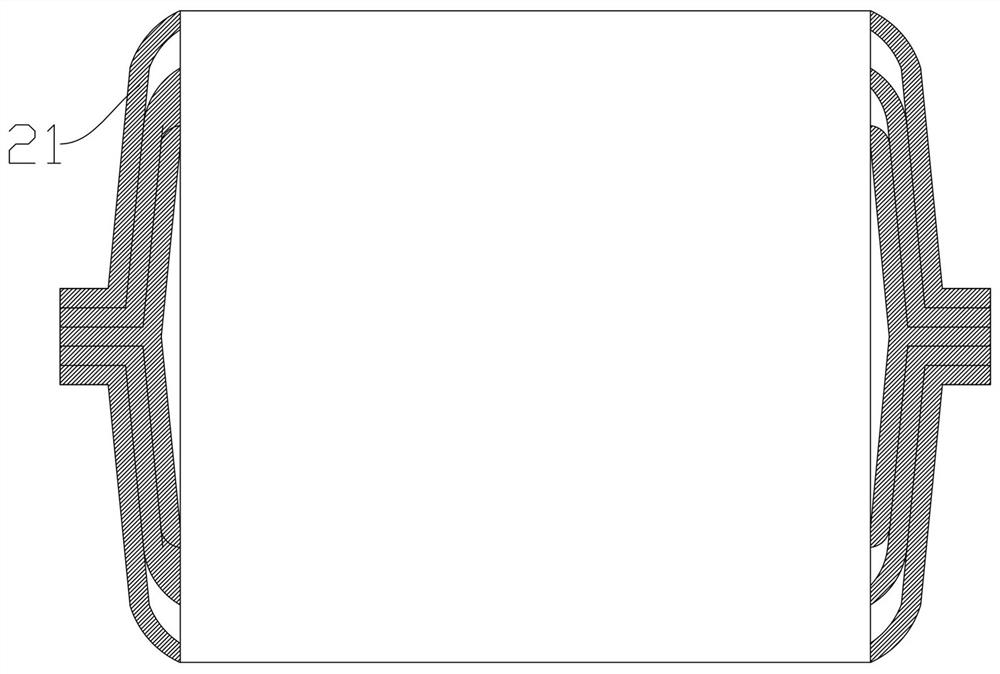

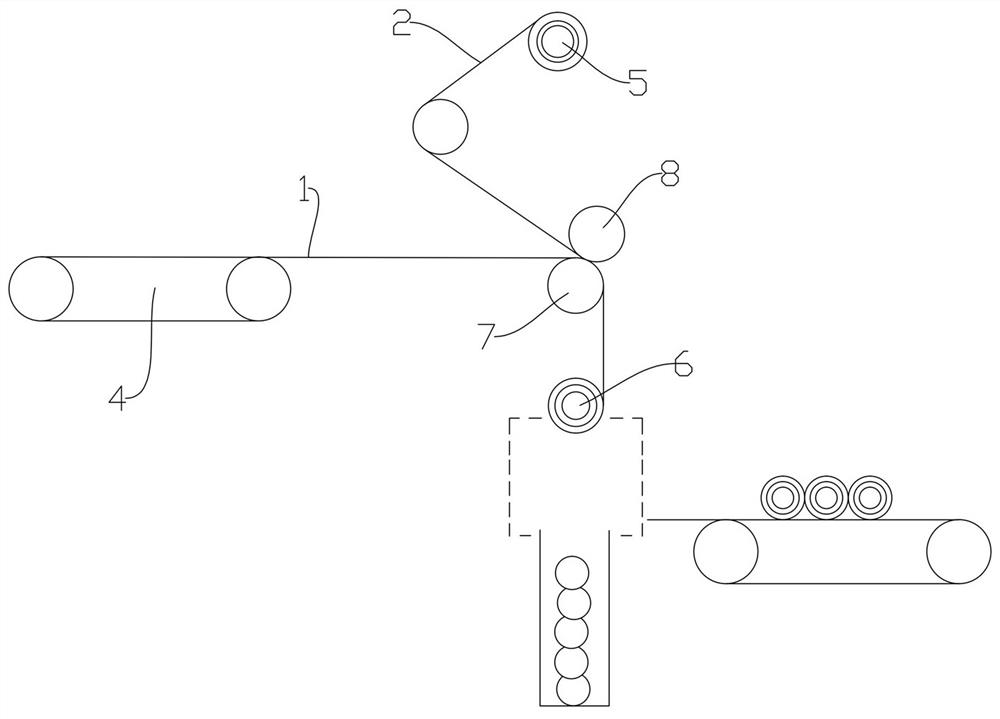

[0036] A heating cigarette re-cigarette leaves storage structure, such as figure 1 As shown, the retrosoma 1 and the isolation membrane 2 include a membrane 2, which can be selected from the PE film or / and a PVDC film. When stored, the re-tobacco 1 is fixed, and the other end is constantly winding around the fixed end, and the paper roll structure is formed, which can reduce the position occupied by the reactive tobacco 1 storage, which is also easy to transport. Such a paper roll structure includes a plurality of radiuss, which are sequentially increased, each of which is not a complete circle, and adjacent single-roll 11 is continuous. The isolation membrane 2 includes a plurality of monoena rings 21. Thus, a single membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com