Preparation method for xylooligosaccharide powder rich in dietary fibers

A technology of xylo-oligosaccharide and dietary fiber, which is applied in the field of preparation of xylo-oligosaccharide powder, can solve problems such as limited use of people, affecting quality, and unsatisfactory preparation of xylo-oligosaccharide powder, so as to improve health and recycle High utilization efficiency, effect of improving intestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

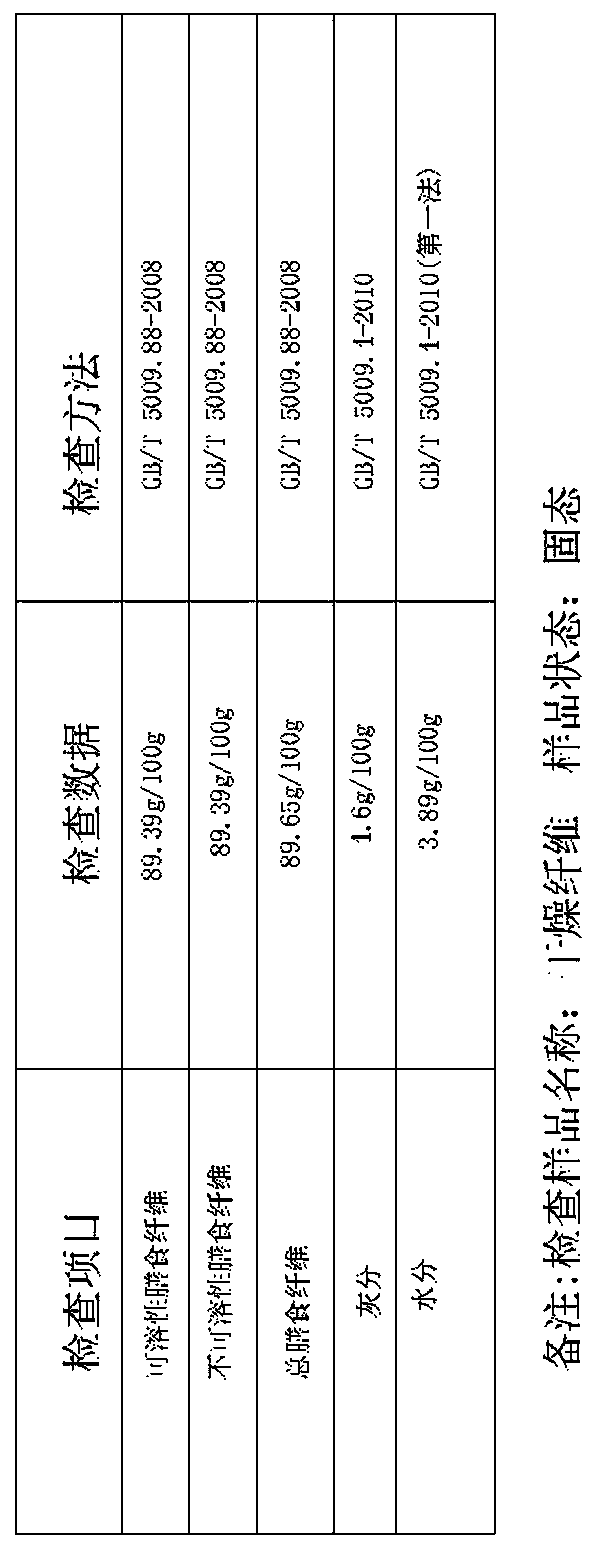

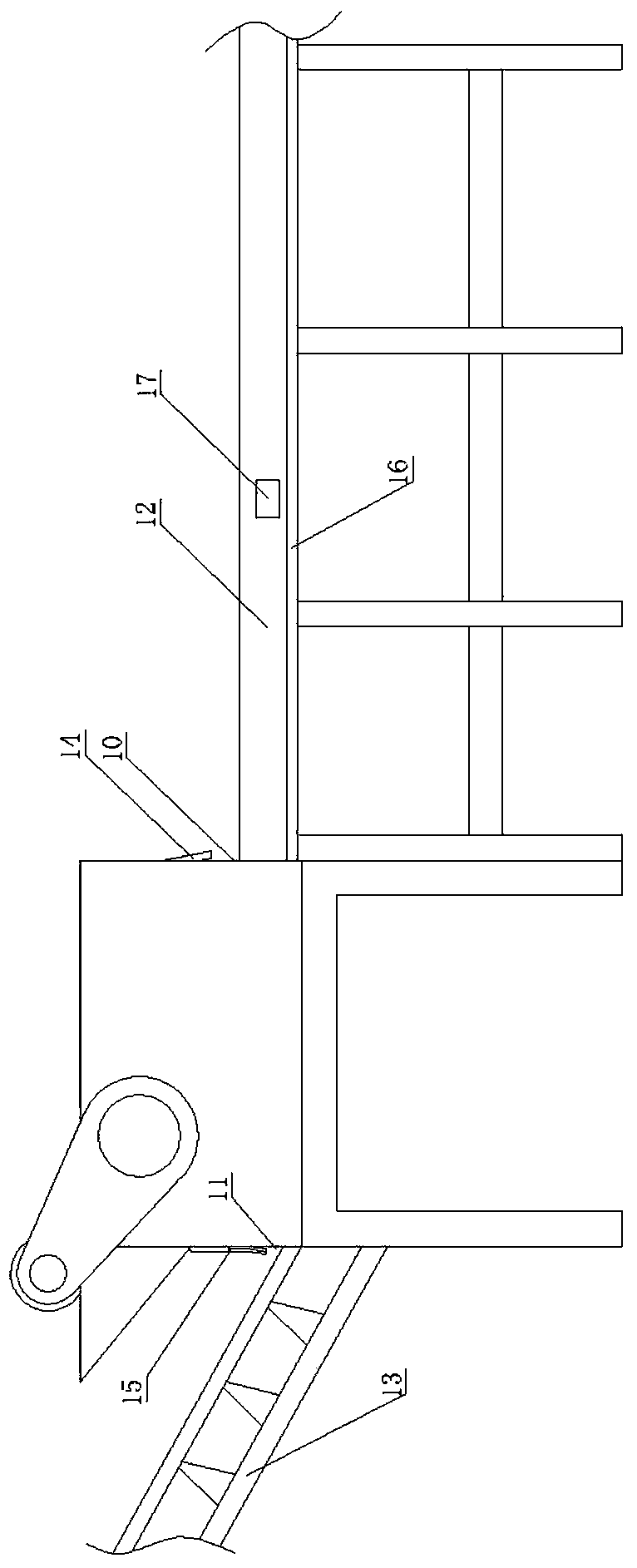

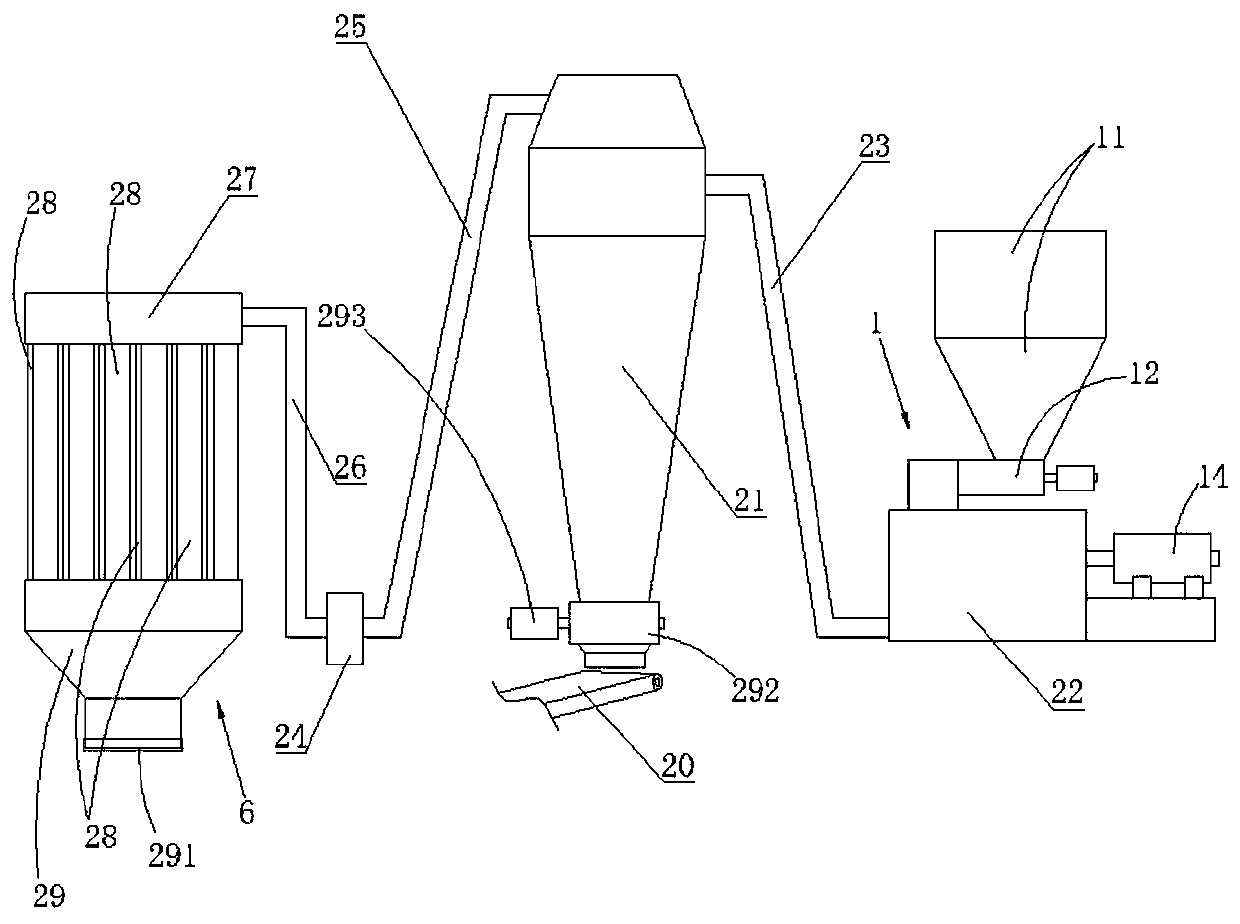

[0025] A preparation method rich in dietary fiber xylo-oligosaccharide powder, it comprises the following steps:

[0026] a) Bamboo raw materials are pretreated, cooked, pulp washed, enzymatically hydrolyzed for the first time, and separated and cleaned to obtain sugar liquid and fiber slag. The method of enzymatic hydrolysis for the first time is: , adding an appropriate amount of water to the extract after pulp washing, and then adding acid, so that the pH value of the first mixed solution is controlled at 3; second, the temperature is raised, so that the temperature of the first mixed solution is controlled at 30 ° C; third, Add enzymes, add an appropriate amount of amylase or xylanase to the first mixed solution, and the content of the amylase or xylanase is controlled at 0.2%; fourth, constant temperature, so that the first mixed solution is in a constant temperature environment, and its control The time is 3 hours; fifth, the temperature is raised so that the temperature...

specific Embodiment 2

[0038] A preparation method rich in dietary fiber xylo-oligosaccharide powder, it comprises the following steps:

[0039] a) Bamboo raw materials are pretreated, cooked, pulp washed, enzymatically hydrolyzed for the first time, and separated and cleaned to obtain sugar liquid and fiber slag. The method of enzymatic hydrolysis for the first time is: , add an appropriate amount of water to the extract after pulp washing, and then add acid, so that the pH value of the first mixed solution is controlled at 5; second, heat up, so that the temperature of the first mixed solution is controlled at 55 ° C; third, Add enzymes, add an appropriate amount of amylase or xylanase to the first mixed solution, and the content of the amylase or xylanase is controlled at 3%; fourth, constant temperature, so that the first mixed solution is in a constant temperature environment, and its control The time is 10 hours; fifthly, temperature rise treatment, so that the temperature of the first mixed s...

specific Embodiment 3

[0044] A preparation method rich in dietary fiber xylo-oligosaccharide powder, it comprises the following steps:

[0045] a) Bamboo raw materials are pretreated, cooked, pulp washed, enzymatically hydrolyzed for the first time, and separated and cleaned to obtain sugar liquid and fiber slag. The method of enzymatic hydrolysis for the first time is: , adding an appropriate amount of water to the extract after pulp washing, and then adding acid, so that the pH value of the first mixed solution is controlled at 7; second, the temperature is raised, so that the temperature of the first mixed solution is controlled at 80 ° C; third, Add enzyme, add an appropriate amount of amylase or xylanase to the first mixed solution, and the content of the amylase or xylanase is controlled at 5%; fourth, constant temperature, so that the first mixed solution is in a constant temperature environment, and its control The time is 20 hours; fifth, the temperature is raised so that the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com