Electromagnetic transmission mechanism of electronic jacquard machine

An electromechanical and electronic jacquard technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of mechanical wear of parts, low transmission efficiency, and difficult maintenance of parts, so as to increase coil current and reduce transmission level , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

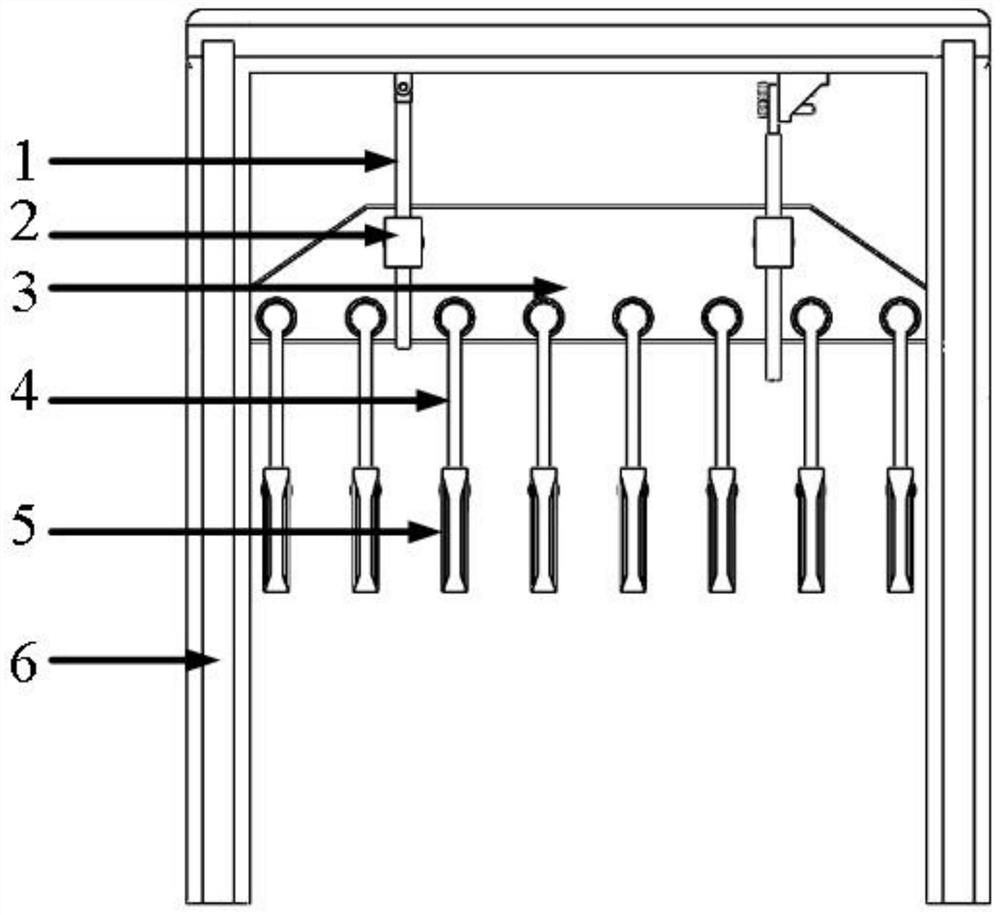

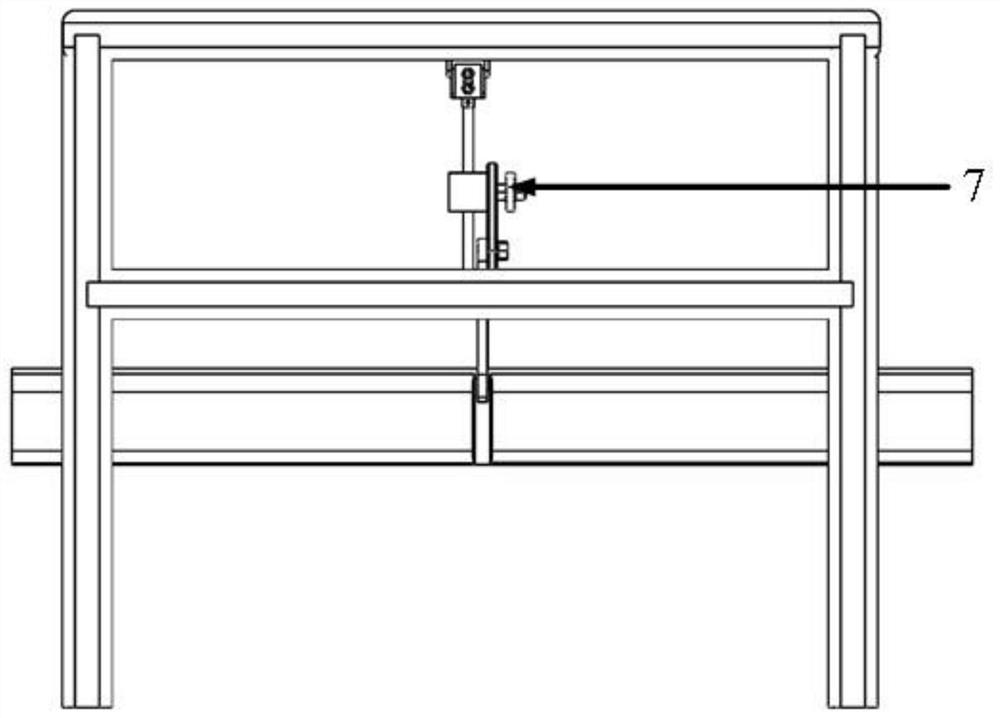

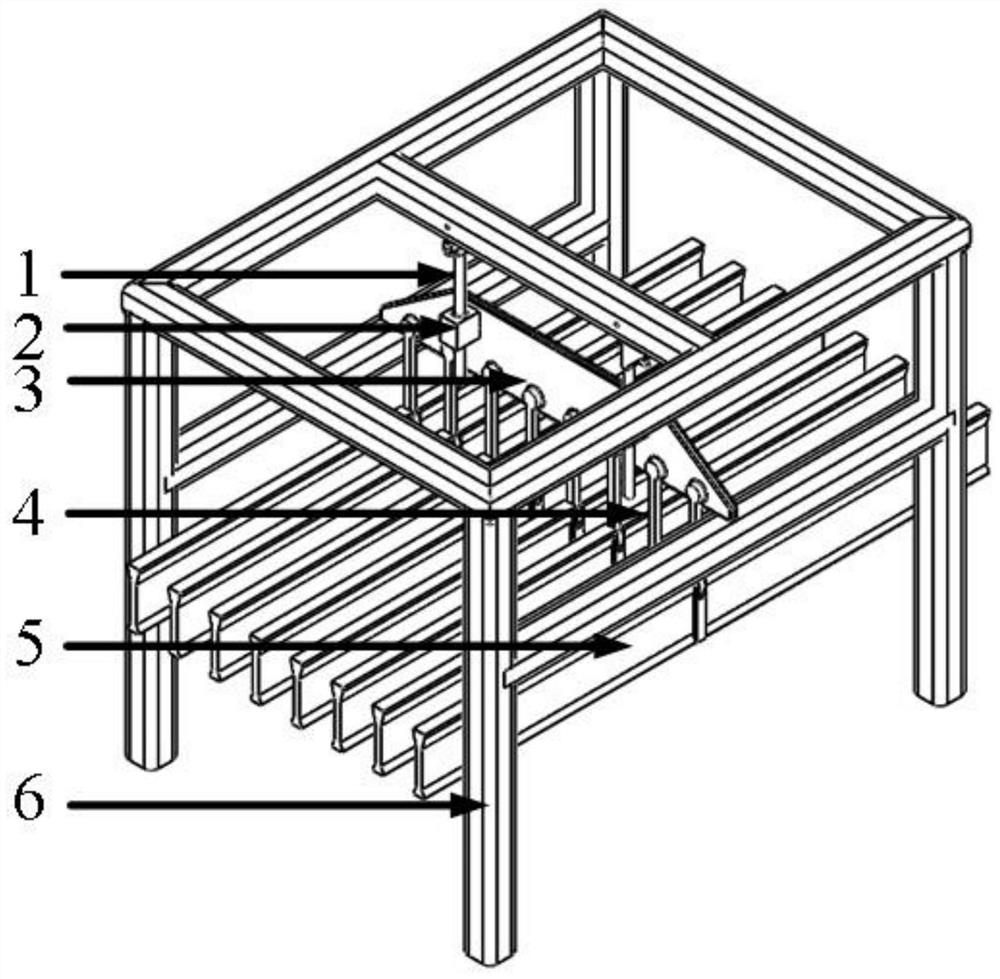

[0049] Such as Figure 1-Figure 3 As shown, the present invention provides an electromagnetic transmission mechanism of an electronic jacquard machine driven by a cylindrical linear motor, which includes: a permanent magnet stator 1; a coil mover assembly 2, including a connecting piece and a mover coil; a broach holder Plate 3; small tie rod part 4; pulling blade 5; frame 6; anti-wear roller 7.

[0050] Such as Figure 6 As shown, the upper end of the permanent magnet stator 1 on the left and the frame 6 form a rotating pair, so that the left permanent magnet stator 1 can swing left and right around a fixed point; the upper end of the permanent magnet stator 1 on the right is fixed on the frame 6 .

[0051] A certain thrust force along the direction of the permanent magnet stator 1 is provided for the coil mover assembly 2 by feeding the changed three-phase alternating current to the coil mover assembly 2 .

[0052] The connecting piece on the coil mover assembly 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com