Hydraulic system and sealed discharging control method for kitchen garbage truck

A technology for hydraulic systems and garbage trucks, which can be used in fluid pressure actuation system testing, garbage receptacles, fluid pressure actuation devices, etc., and can solve problems such as troublesome operation, increased operator work, and garbage leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

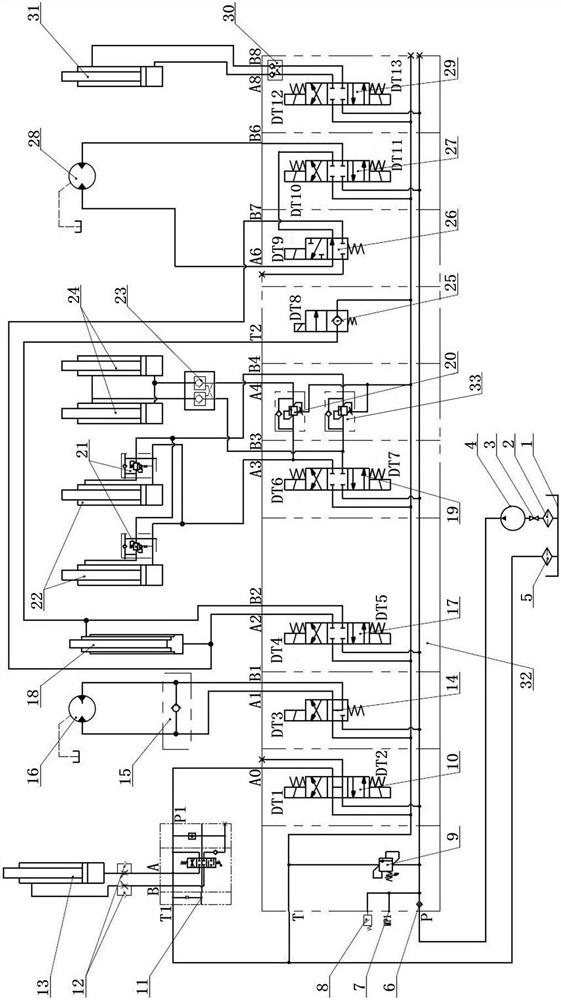

[0033] The embodiment of the hydraulic system of the kitchen garbage truck in the present invention is as figure 1 As shown, it includes a hydraulic pump 4, a control valve group 32 composed of multiple control elements, and executive elements correspondingly connected to each control element, wherein the hydraulic pump 4 is powered by a gearbox power take-off or a motor, and sucks oil from the oil tank 1 , through the oil suction filter 2 and the shut-off valve 3 to the oil inlet of the hydraulic pump 4, and then from the oil outlet of the hydraulic pump 4 to provide pressure oil to the control valve group 32 through the outer oil inlet pipeline, the control valve group 32 is provided with an inner inlet The oil pipeline, the outer oil inlet pipeline and the inner oil inlet pipeline are connected.

[0034] The actuators in this embodiment include: a lifting cylinder 13 for connecting with the trash can lifting mechanism, a water pump motor 16 for connecting with the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com