Pushing plate assembly with auxiliary film assembly function

A push plate and function technology, which is applied in the field of push plate components with auxiliary film function, can solve the problems that the door cannot be completely closed and the positive pressure environment of the machine is destroyed, so as to prevent the generation of static electricity, reduce the generation rate, and avoid accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

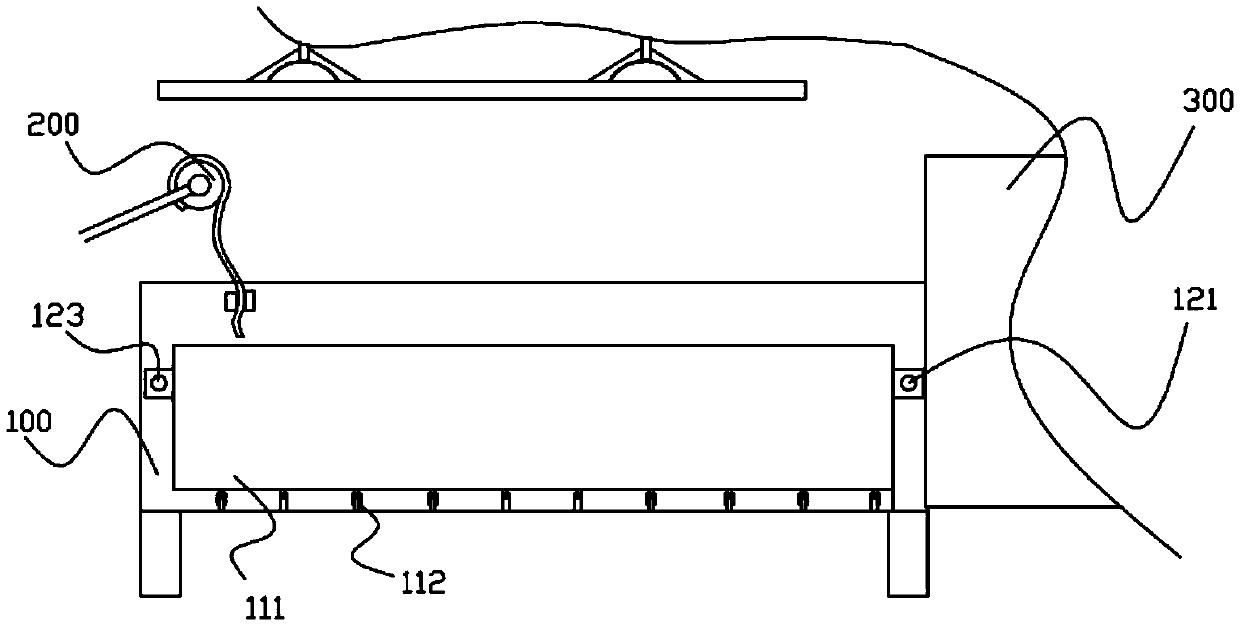

[0044] In order to solve the problem of BL self-assembly, the prism sheet must be torn off inside the machine 400 due to its easy contamination, and the film accumulates in the film receiving area, blocking the vent hole at the bottom of the machine 400, thereby disturbing the top-down airflow of the lens unit , forming a turbulent flow, causing the foreign matter on the film to disturb in the air and fall to the lens after the film is torn off, so that the assembled BL has white spots, black spots, white stripes (pollution or scratches), or water dancing and other defective products, and the defects caused by prism sheets are extremely difficult to repair, and can only be repaired by replacing new prism sheets, and the maintenance cost is high, and the demand for human resources is large. Therefore, this embodiment provides a solution to BL from the source. In the automatic assembly line, the film frame 100 with bad problems caused by the introduction of foreign matter in the ...

Embodiment 2

[0069] This embodiment provides a push pedal assembly with the function of auxiliary film installation. The difference between the push pedal assembly of this embodiment and the above-mentioned embodiment 1 is that it also includes an auxiliary push assembly:

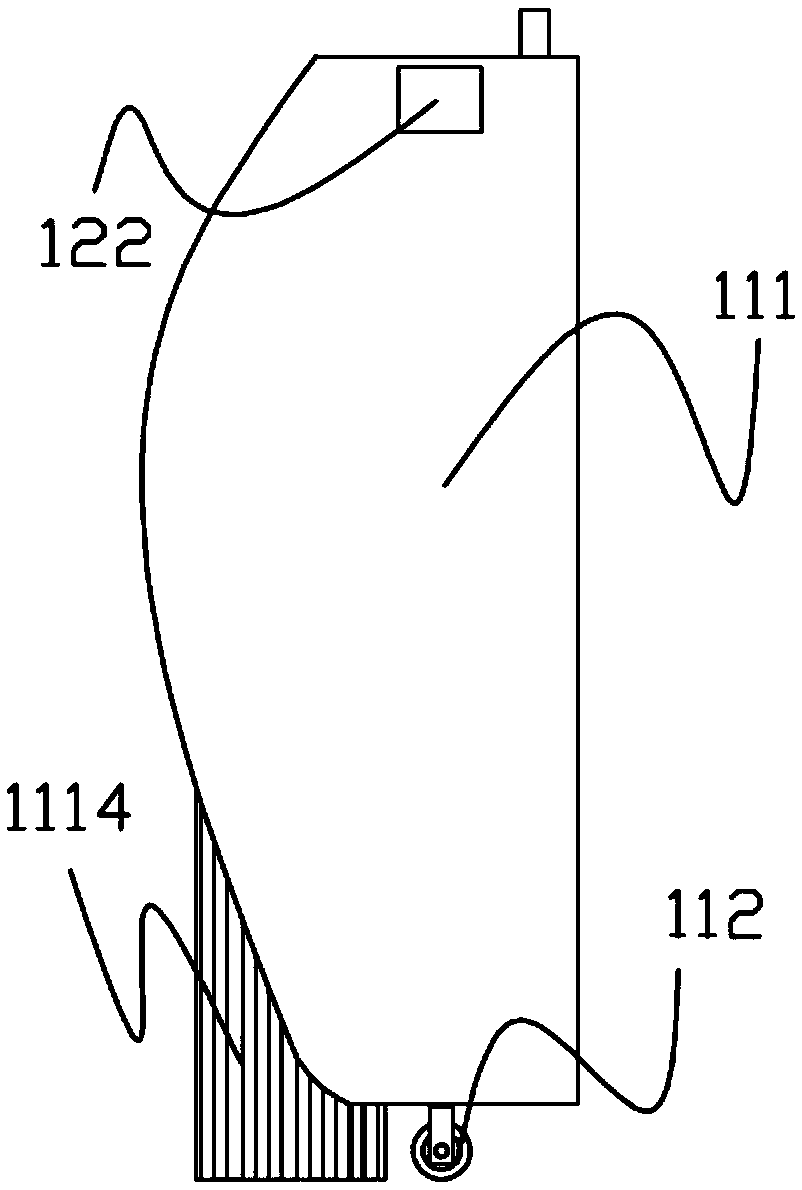

[0070] In order to enable the push plate to push the lens film in the film stacking frame into the garbage bag as much as possible, an auxiliary pushing mechanism 130 is also provided on the pushing film plate 111. The auxiliary pushing mechanism 130 includes an auxiliary pushing plate 131, a shearing structure 132, a guide Seat 133 and transmission part 134, the horizontal installation groove 135 that runs through arc surface 1112 is provided on the pushing film plate 111, is provided with driving motor, the driving gear that is fixed on the output shaft of driving motor in the horizontal installation groove 135; 132 is used to drive the auxiliary push plate 131 to extend or retract.

[0071] The guide seat 133 is fixe...

Embodiment 3

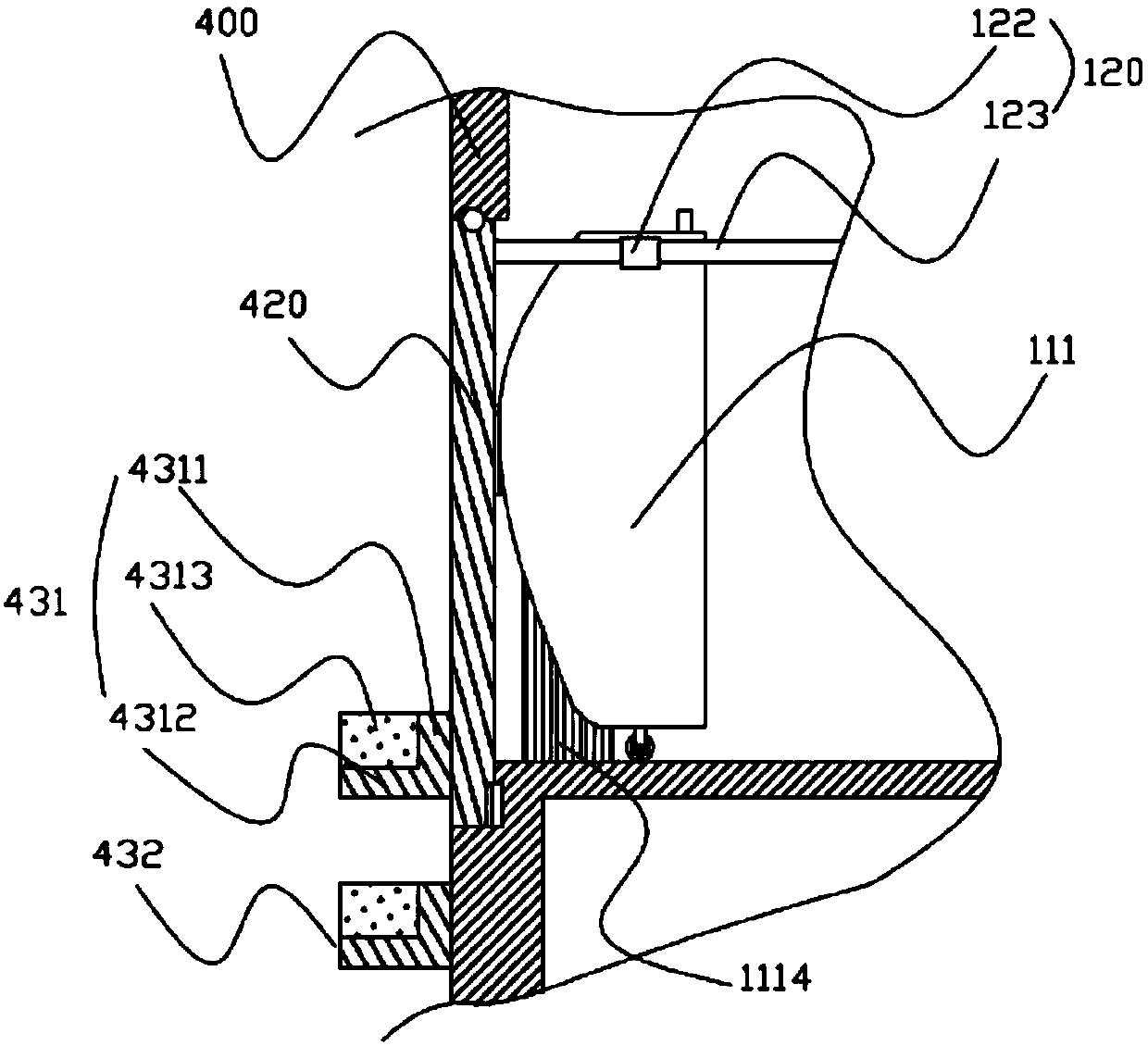

[0078] This embodiment also discloses a control system for an automatic film harvesting mechanism, including:

[0079]The pressure sensor 422 is fixed on the inside of the dodge door 420, and is used to detect the pressure information between the push plate and the dodge door 420, and feed back the detected pressure information to the controller;

[0080] a controller, set in the control area of the machine 400, for receiving and processing pressure information;

[0081] The servo motor is connected to the signal output end of the controller through the motor driver, and is used to control the working state of the push film plate 111 through the controller;

[0082] The electromagnetic lock 421 is arranged at the bottom of the film outlet 410 and is connected to the signal output end of the controller for opening and closing the movable door 420 according to the pressure information received by the controller;

[0083] The controller is PLC control system;

[0084] The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com