Water transportation channel safety management device

A technology of safety management and waterway, which is applied in the direction of ship safety, transportation and packaging, and the use of hydrofoils to reduce ship movement on the surrounding water surface. It can solve the problems of easy left and right tilting of the hull and capsize, so as to provide integrity and improve balance. The effect of increasing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

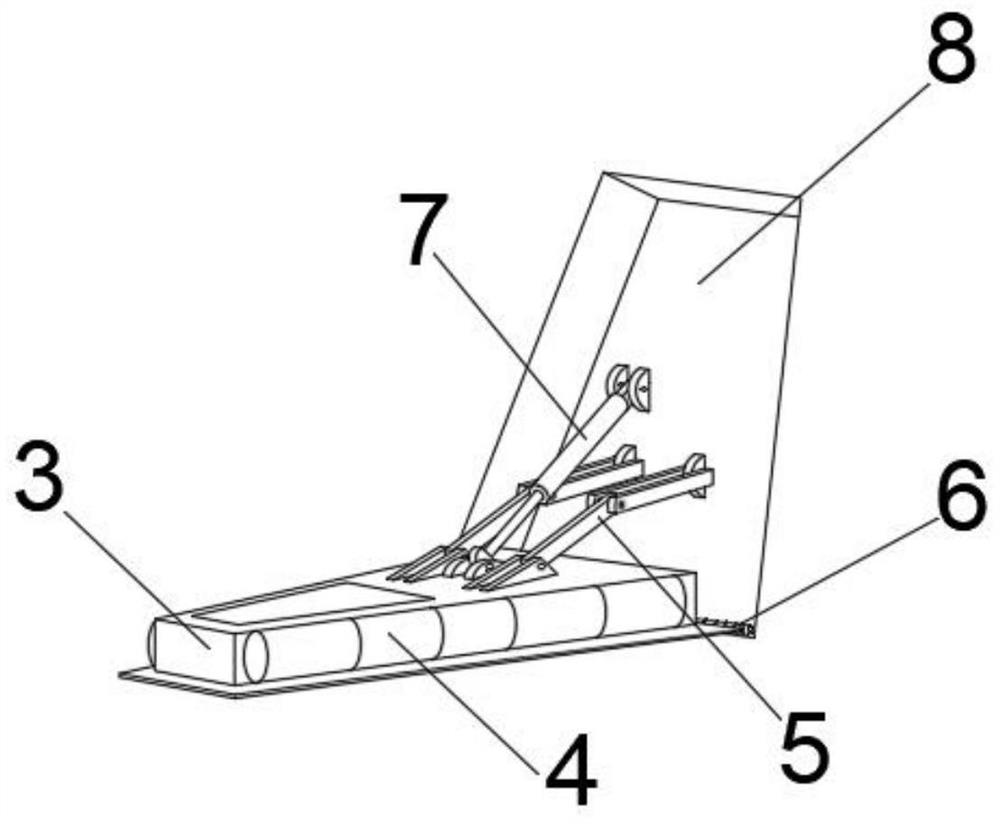

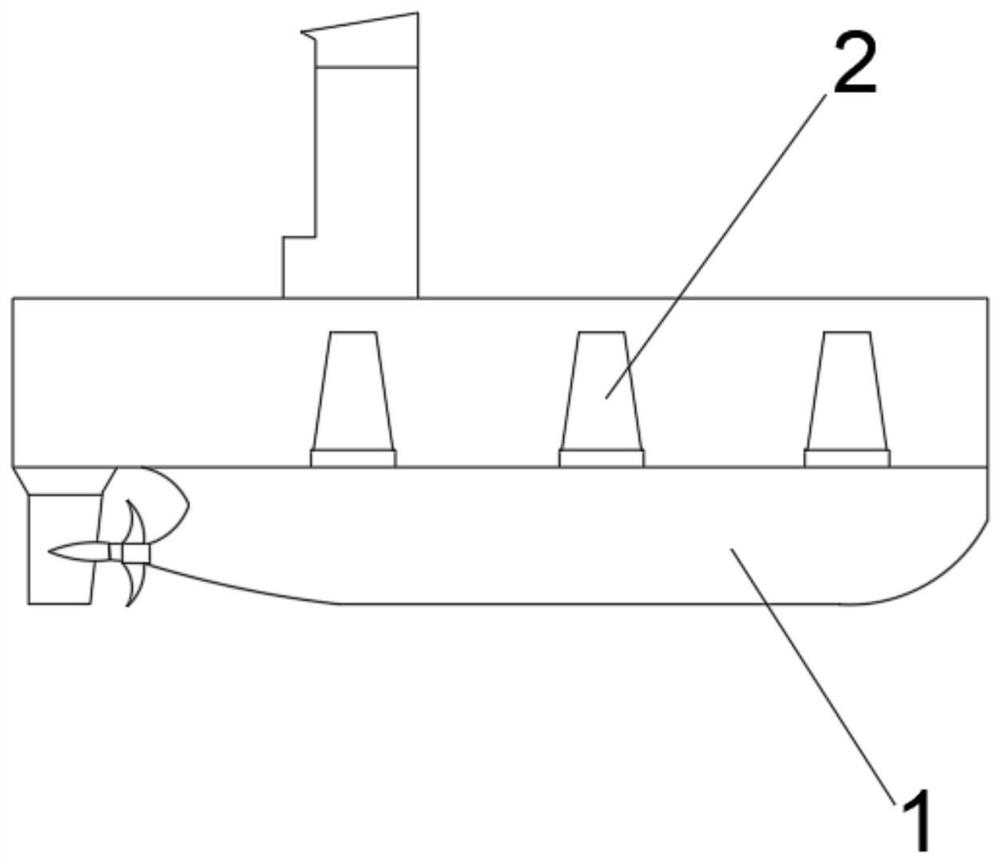

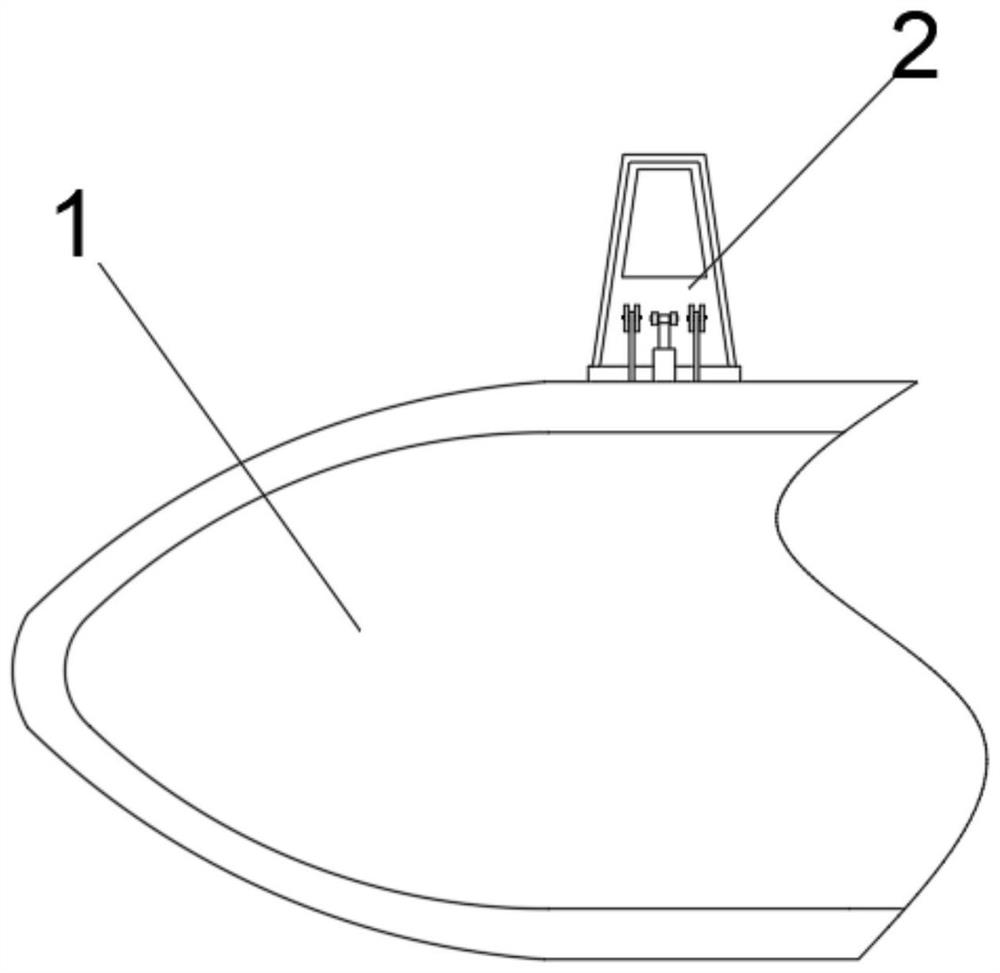

[0034] Such as Figure 1 to Figure 8 As shown, a waterway safety management device includes a hull 1, a plurality of grooves 8 are provided on both sides of the hull 1, and a protection device 2 is movable in the groove 8, and the protection device 2 includes a The groove 8 is connected to the rotating plate 3 by the rotating shaft 6, the driving device 7 and the rotating mechanism 5 that are fixedly connected to the rotating plate 3 and the inner wall of the groove 8 at both ends, and are arranged on the rotating plate 3. The expansion mechanism 4 and the deformation mechanism arranged inside the rotating plate 3 to control the expansion and contraction of the expansion mechanism 4; Block 71 and second fixed block 76, the rotary block 72 that is rotatably connected with the first fixed block 71 and the hydraulic cylinder 74 that is respectively connected with the rotary block 72 and the second fixed block 76, the output of the hydraulic cylinder 74 The shaft 73 is fixedly co...

Embodiment 2

[0038] Such as Figure 1 to Figure 6 , Figure 9 and Figure 10As shown, a waterway safety management device includes a hull 1, a plurality of grooves 8 are provided on both sides of the hull 1, and a protection device 2 is movable in the groove 8, and the protection device 2 includes a The groove 8 is connected to the rotating plate 3 by the rotating shaft 6, the driving device 7 and the rotating mechanism 5 that are fixedly connected to the rotating plate 3 and the inner wall of the groove 8 at both ends, and are arranged on the rotating plate 3. The expansion mechanism 4 and the deformation mechanism arranged inside the rotating plate 3 to control the expansion and contraction of the expansion mechanism 4; Block 71 and second fixed block 76, the rotary block 72 that is rotatably connected with the first fixed block 71 and the hydraulic cylinder 74 that is respectively connected with the rotary block 72 and the second fixed block 76, the output of the hydraulic cylinder 74...

Embodiment 3

[0042] Such as Figure 1 to Figure 6 , Figure 11 and Figure 12 As shown, a waterway safety management device includes a hull 1, a plurality of grooves 8 are provided on both sides of the hull 1, and a protection device 2 is movable in the groove 8, and the protection device 2 includes a The groove 8 is connected to the rotating plate 3 by the rotating shaft 6, the driving device 7 and the rotating mechanism 5 that are fixedly connected to the rotating plate 3 and the inner wall of the groove 8 at both ends, and are arranged on the rotating plate 3. The expansion mechanism 4 and the deformation mechanism arranged inside the rotating plate 3 to control the expansion and contraction of the expansion mechanism 4; Block 71 and second fixed block 76, the rotary block 72 that is rotatably connected with the first fixed block 71 and the hydraulic cylinder 74 that is respectively connected with the rotary block 72 and the second fixed block 76, the output of the hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com