Patents

Literature

30results about How to "Make sure to open" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

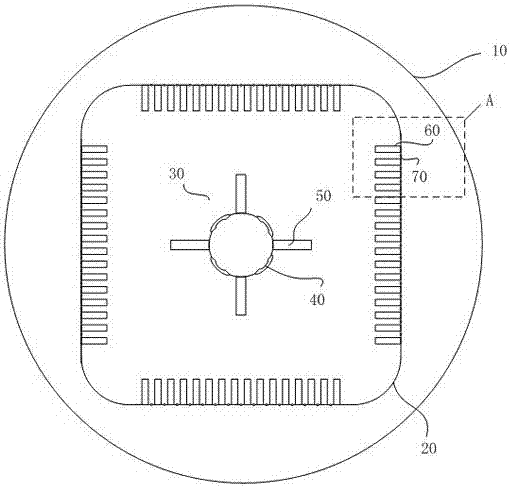

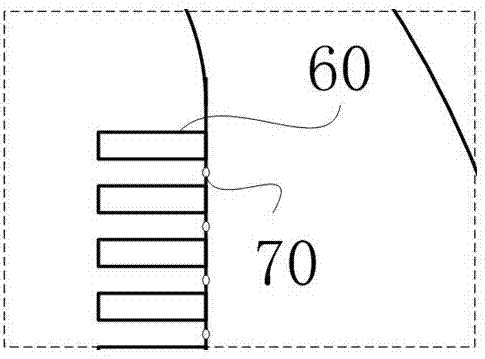

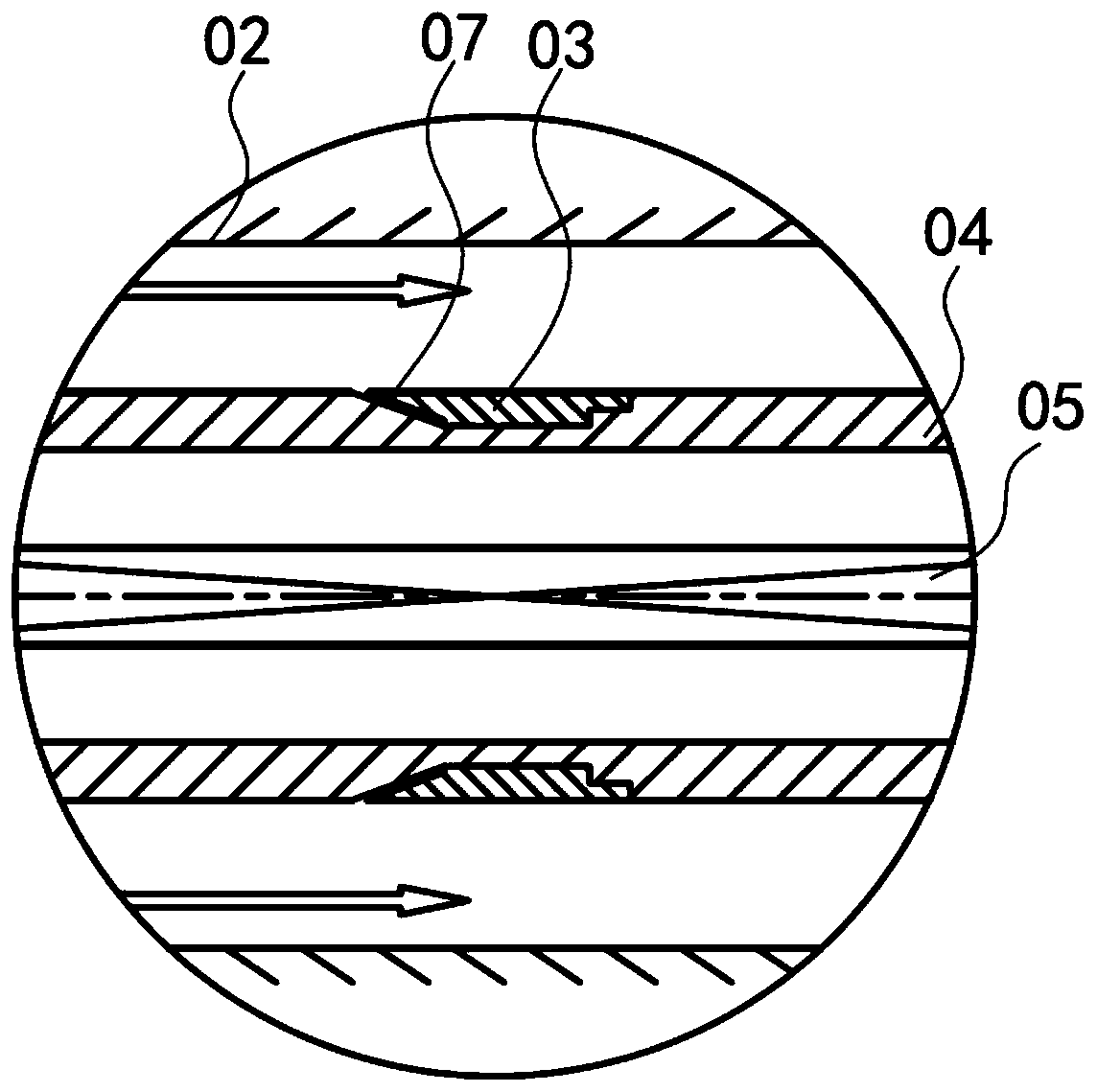

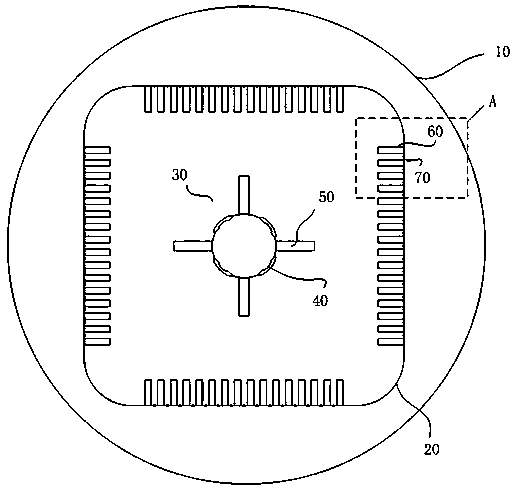

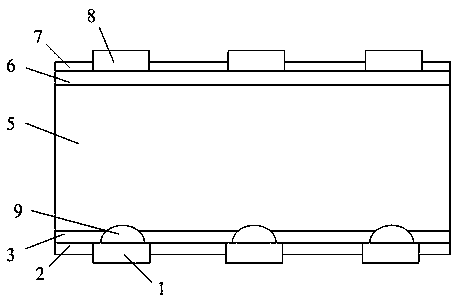

Tube type PERC single-sided solar cell, preparation method thereof and special equipment thereof

ActiveCN107256894AReduce the ratio of scratchesReduce impact forceFinal product manufactureSemiconductor/solid-state device manufacturingScratchingSilica membrane

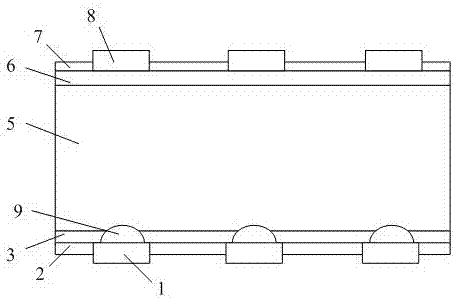

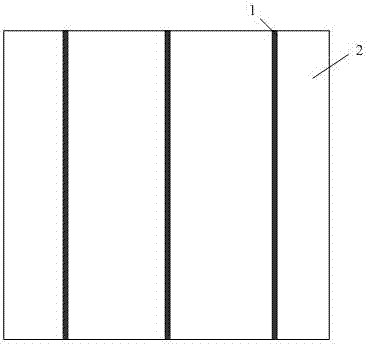

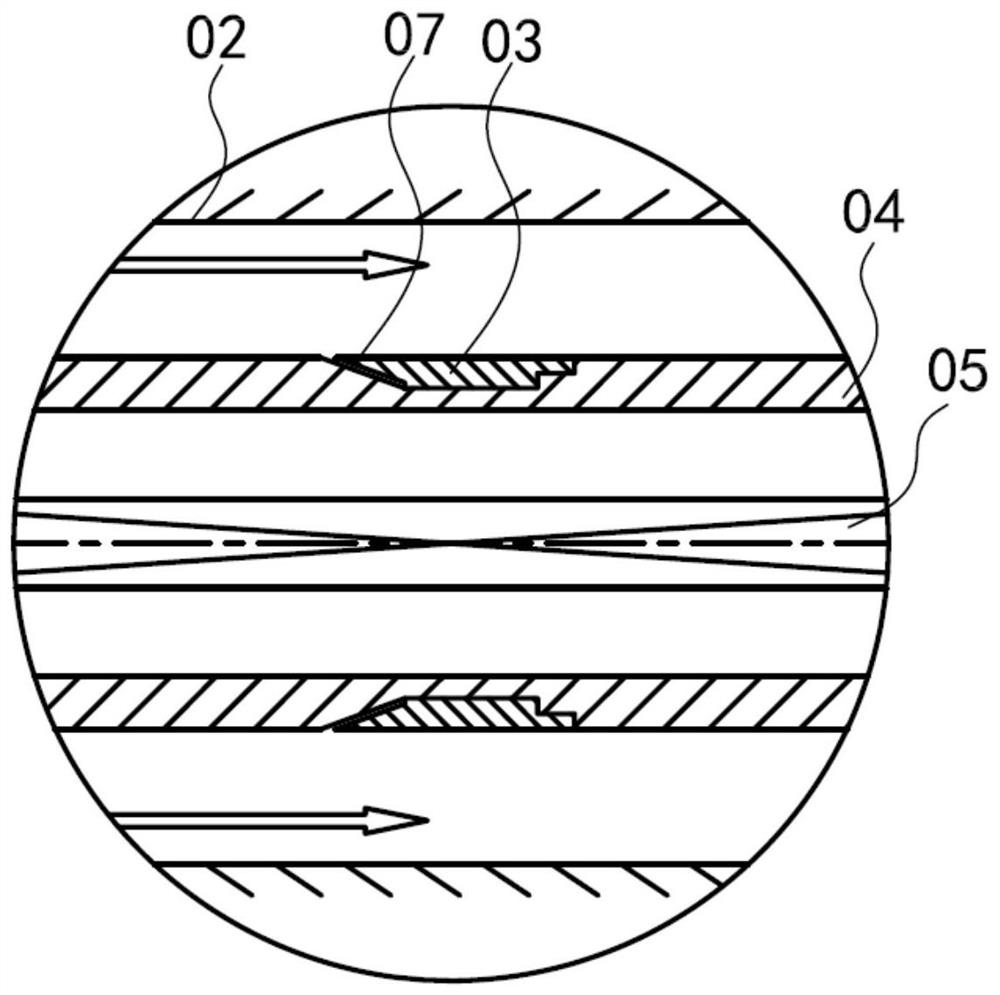

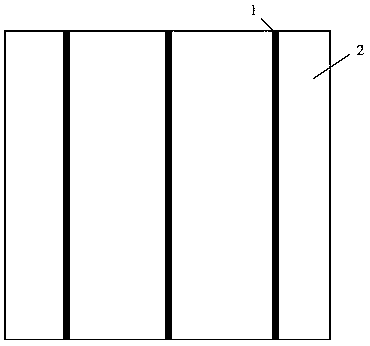

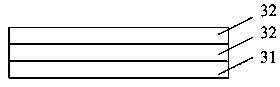

The invention discloses a tube type PERC single-sided solar cell, which comprises a main silver back gate, an all-aluminum back electric field, a back-side composite film, a P-type silicon, an N-type emitting electrode, a front-side passivation film and a positive silver electrode. The back-side composite film is composed of one or more selected from an aluminum oxide film, a silicon dioxide film, a silicon oxynitride film and a silicon nitride film and is deposited at the back of a silicon chip by adopting tube type PECVD equipment. The tube type PECVD equipment comprises four gas pipelines of silane, ammonia, trimethyl aluminum and laughing gas. The appliance of the tube type PECVD equipment, used for loading and unloading silicon chips, is a graphite boat. The depth of a sticking point groove of the graphite boat is 0. 5-1 mm. The invention also discloses a preparation method and special equipment of the tube type PERC single-sided solar cell. According to the invention, the photoelectric conversion efficiency is high. Meanwhile, the appearance yield and the EL yield are high. The problems of scratching, winding and plating can be solved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH +1

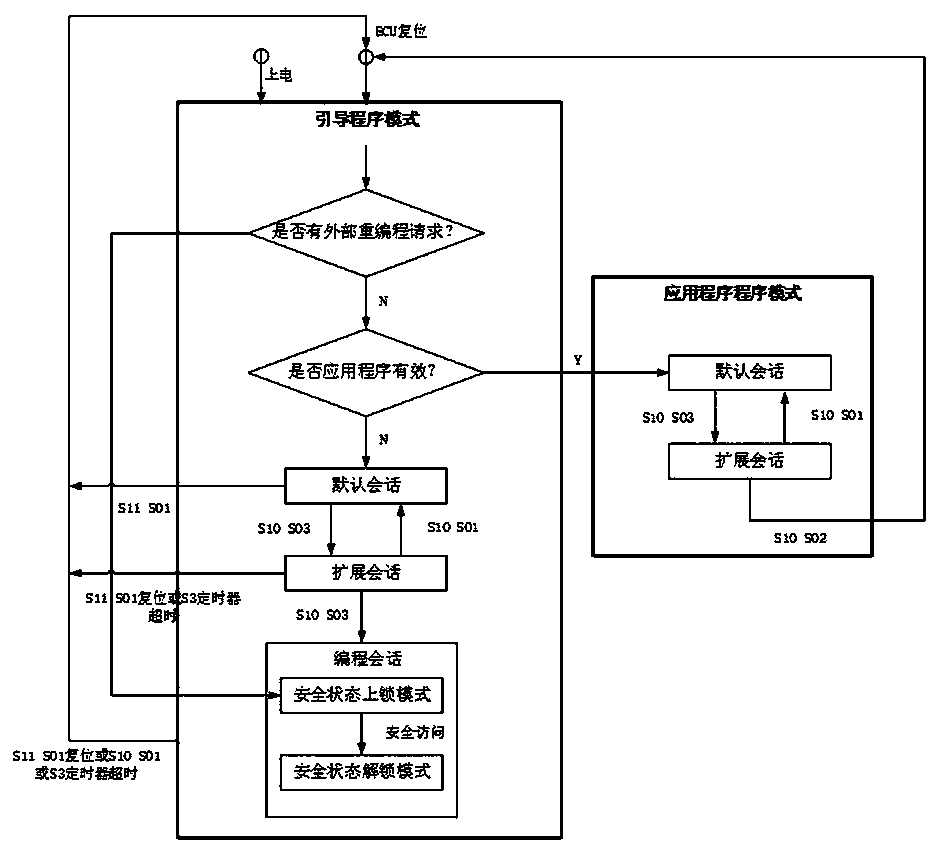

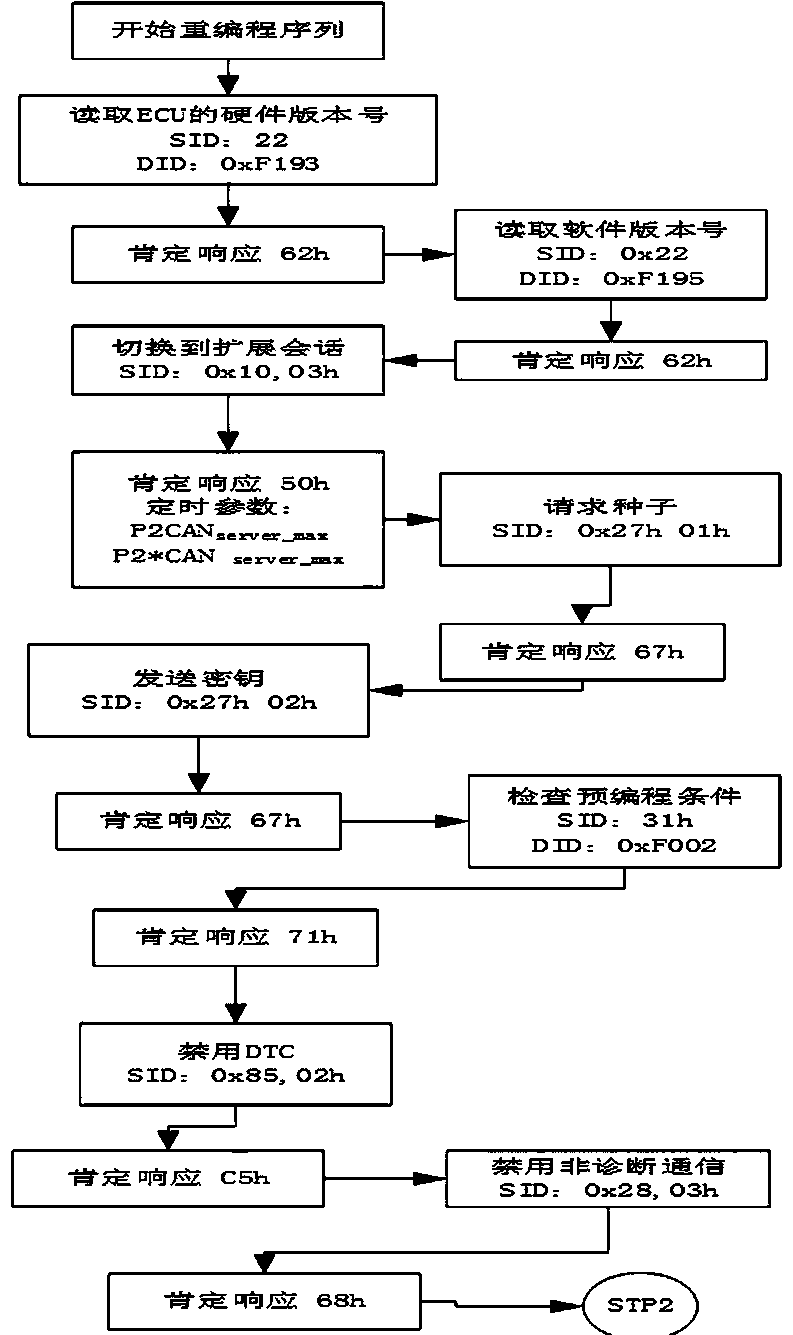

Method for realizing remote upgrading of vehicle ECU based on UDS communication protocol

PendingCN111327689AMake sure to openAvoid functioProgramme controlComputer controlIn vehicleData management

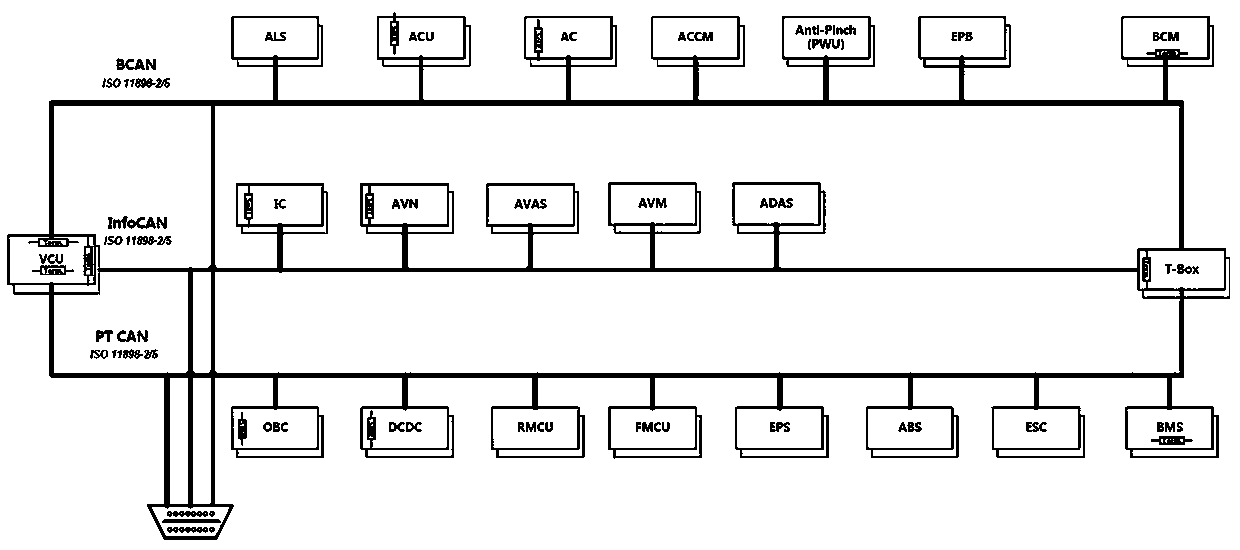

The invention relates to vehicle ECU remote upgrading equipment and a vehicle ECU remote upgrading method, and provides a method for realizing vehicle ECU remote upgrading based on a UDS communicationprotocol in allusion to the current situation that different vehicle factories need to independently develop respective vehicle ECU remote upgrading systems. The method is based on CAN communicationdata of a vehicle. A vehicle UDS diagnosis protocol and a remote monitoring platform scheme are compiled; remote data upgrading of the vehicle ECU is achieved through the hardware vehicle-mounted terminal 4G module, manual offline upgrading of the ECU is not needed any more, the upgrading time of the vehicle ECU can be set at the background, and the ECU is upgraded automatically through remote networking after the set time is up. An ECU delivery recovery mechanism is specified in the UDS protocol, and the situations of ECU crash damage, data loss and the like caused by networking failure in the upgrading process are avoided. By establishing the cloud platform, the vehicle-mounted hardware and the data management algorithm and combining the UDS diagnosis protocol for encryption security access, ECU upgrading is safer and more convenient.

Owner:DAYUN AUTOMOBILE CO LTD

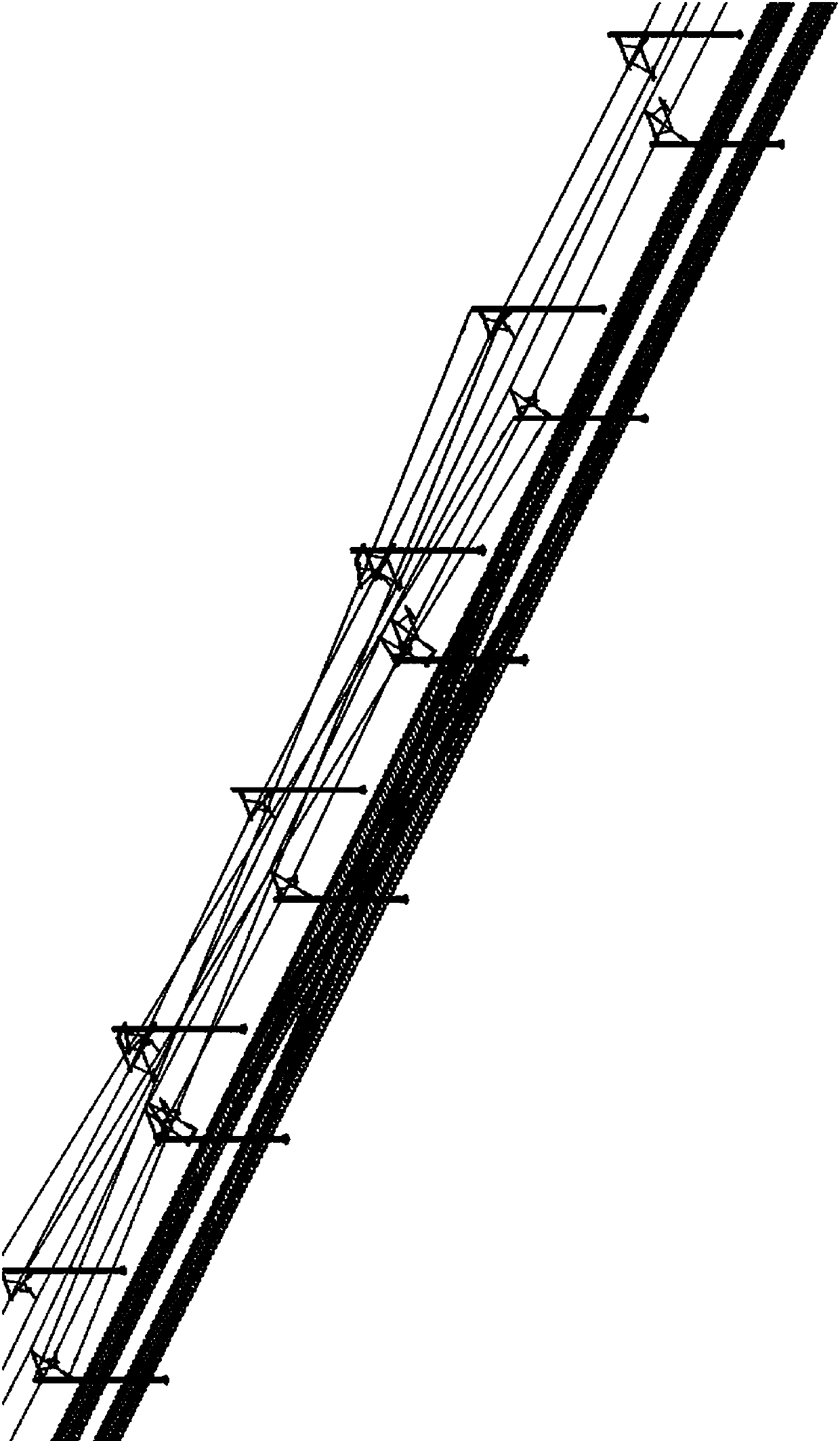

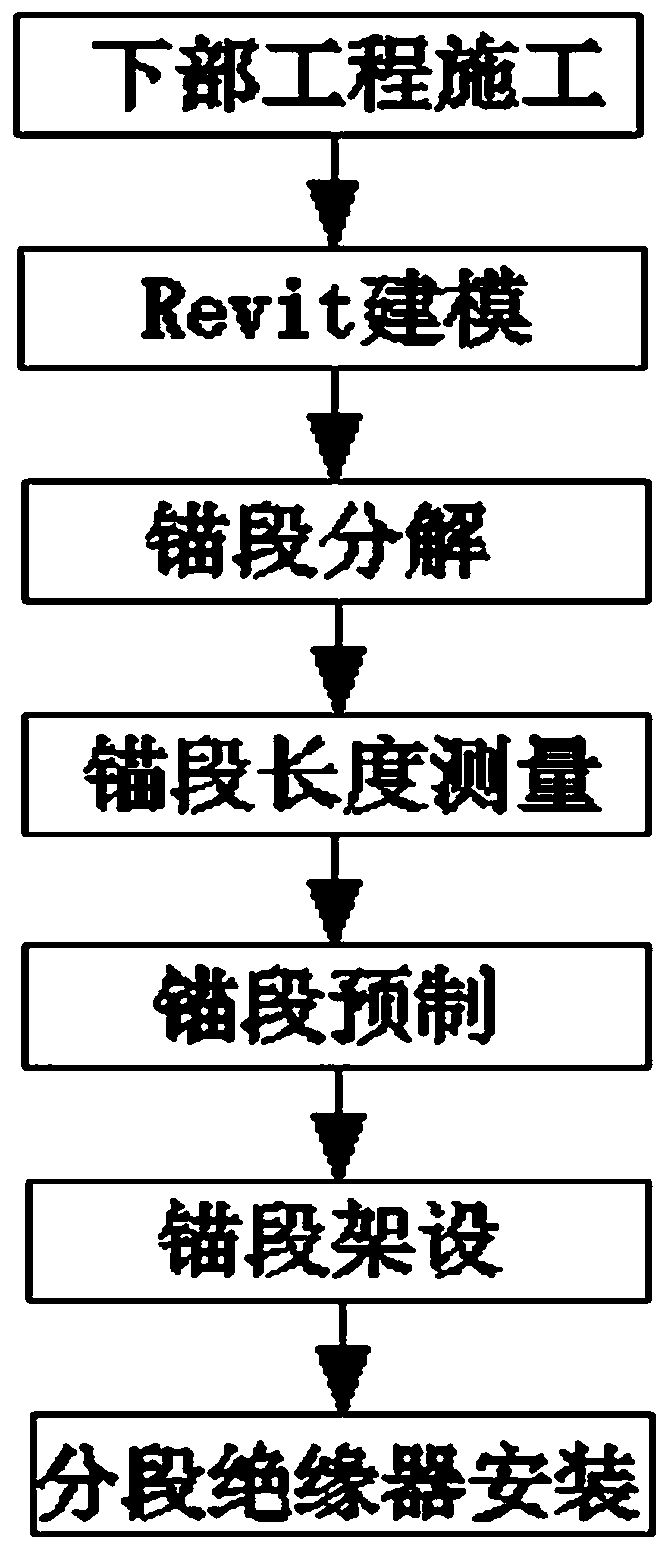

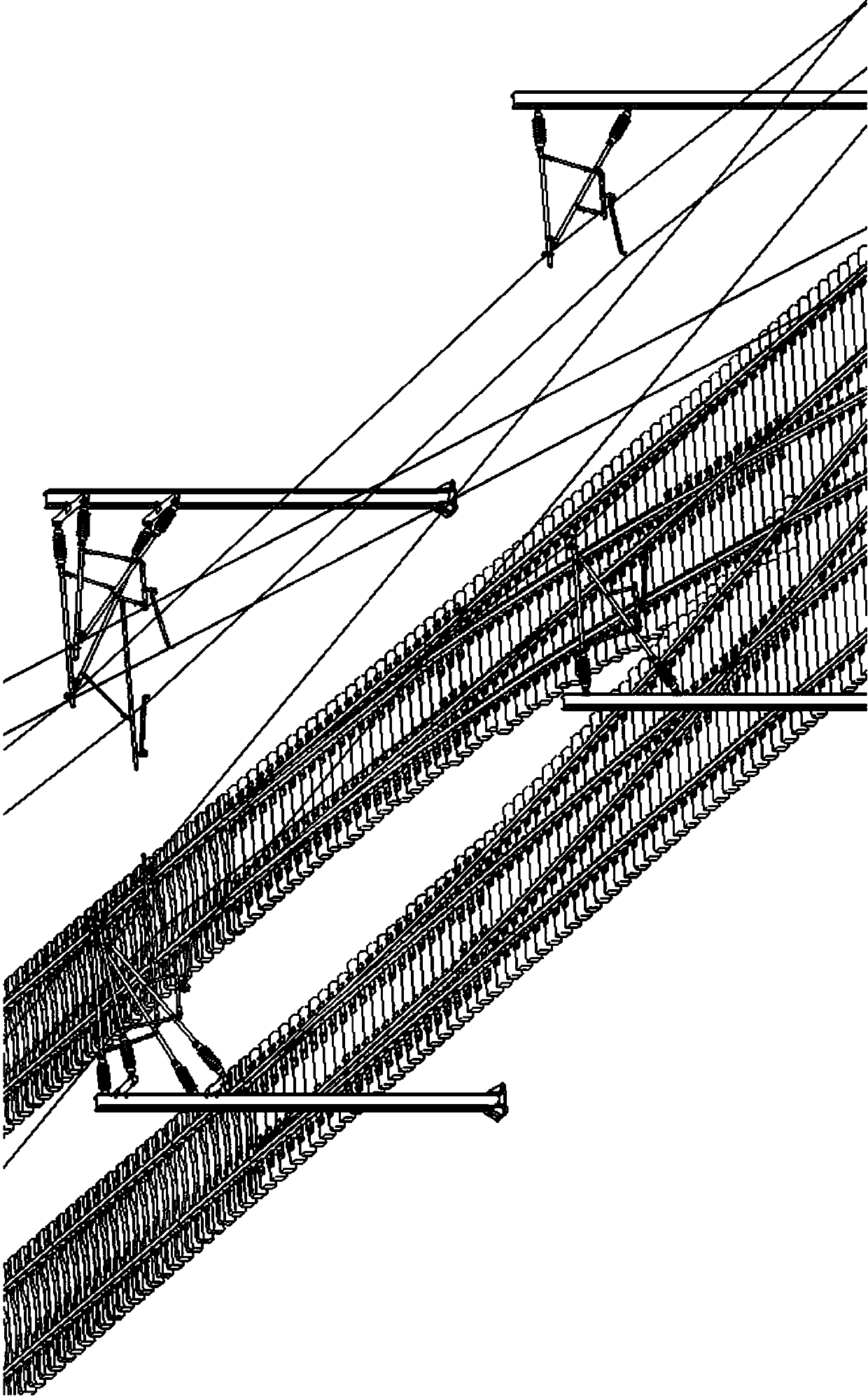

Construction method for erecting electrified railway uplink and downlink crossover contact net

ActiveCN110641319AMake sure to openReduce the time to hang the sunroofTrolley linesControl theoryPrefabrication

The invention belongs to the technical field of electrified railway contact net construction, and particularly relates to a construction method for erecting an electrified railway uplink and downlinkcrossover contact net. The construction method for erecting the electrified railway uplink and downlink crossover contact net is good in construction effect. The construction method includes the following steps that 1), an anchoring section is divided into two parts from the position of an uplink and downlink crossover section insulator, the distances between the center of the section insulator and an adjacent main track and between the center of the section insulator and the center of a crossover line are equal, and the center of the section insulator is a decomposition point; the anchoring section from the decomposition point to a hard anchor is L1, and the prefabrication length is Lx; anchoring section prefabrication is carried out according to the prefabrication length Lx of the anchoring section; the anchoring section from the decomposition point to a full compensation lower anchor end is L2, and the total length of the anchoring section is L; 2), anchor hauling is carried out, the anchoring section L1 and the anchoring section L2 are synchronously erected, a first insulator is connected, anchor falling is carried out, suspension adjusting is carried out, and power is supplied; and 3), the first insulator is replaced with the section insulator through a following skylight.

Owner:ELECTRIC ENG CO LTD OF CHINA RAILWAY NO 9 GRP

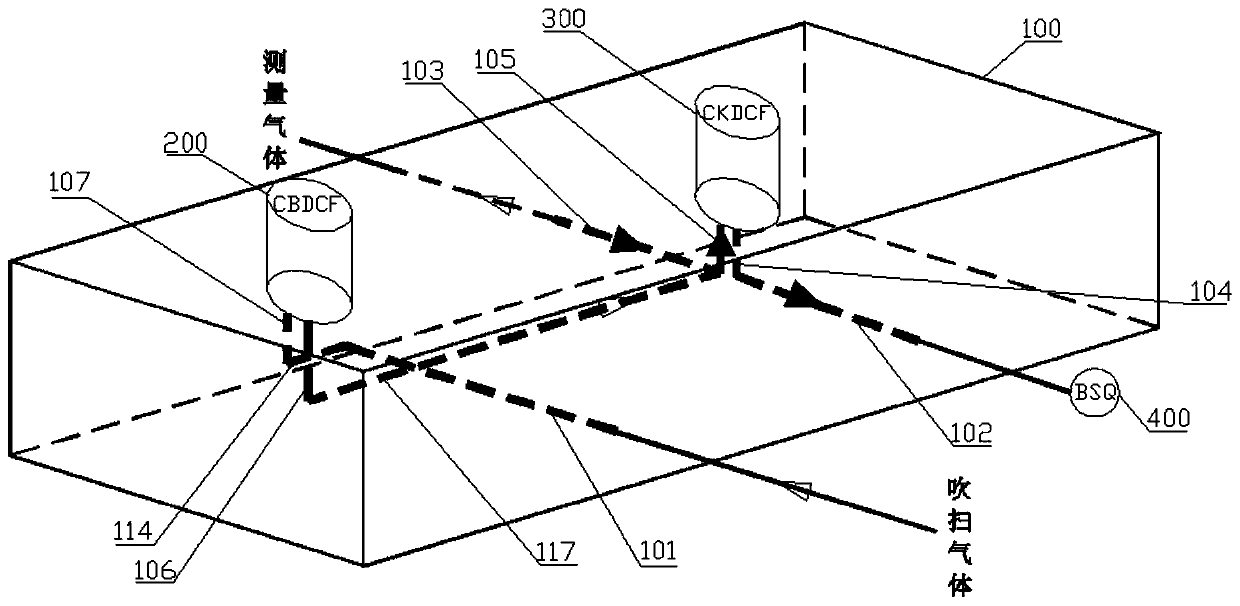

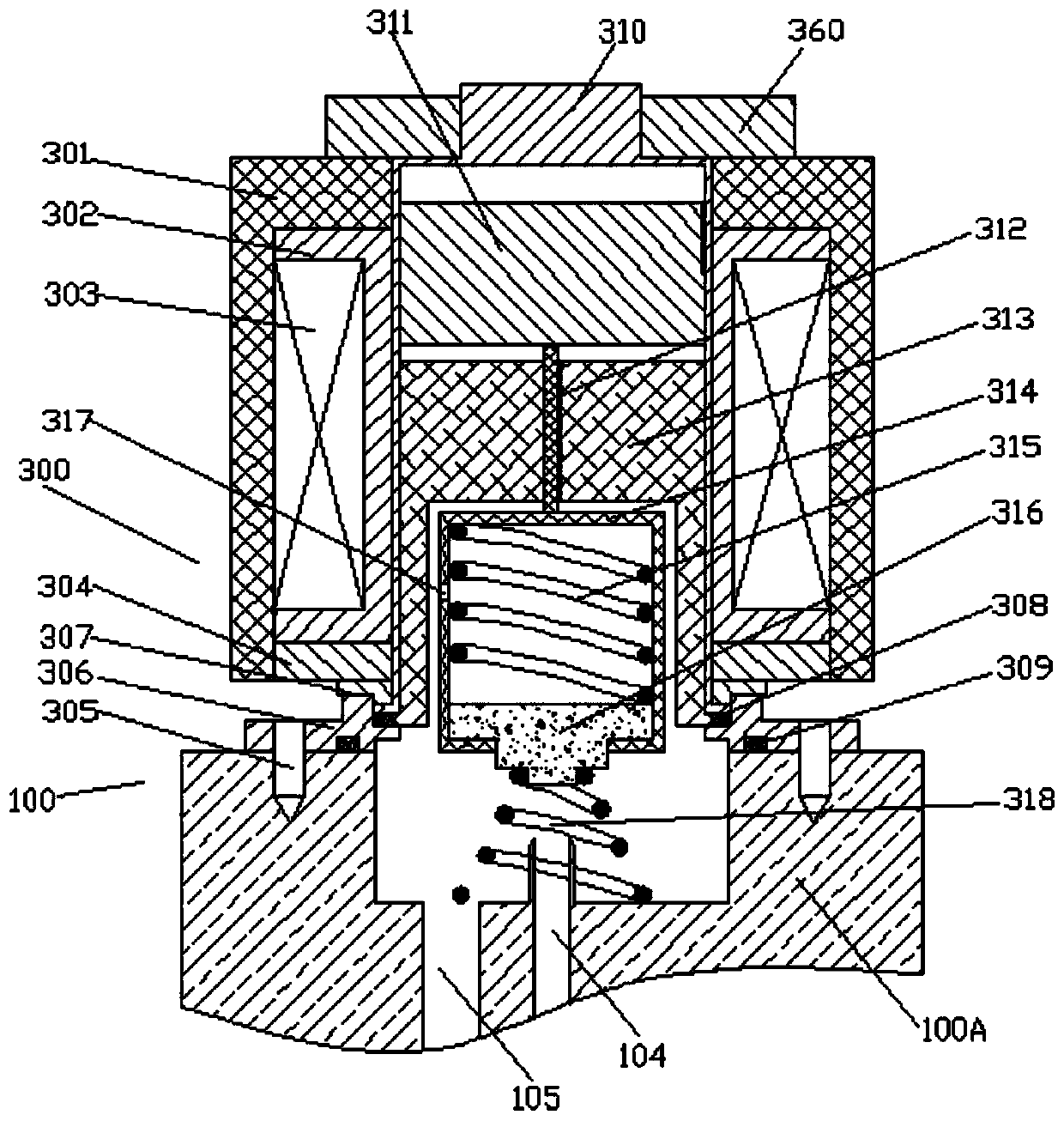

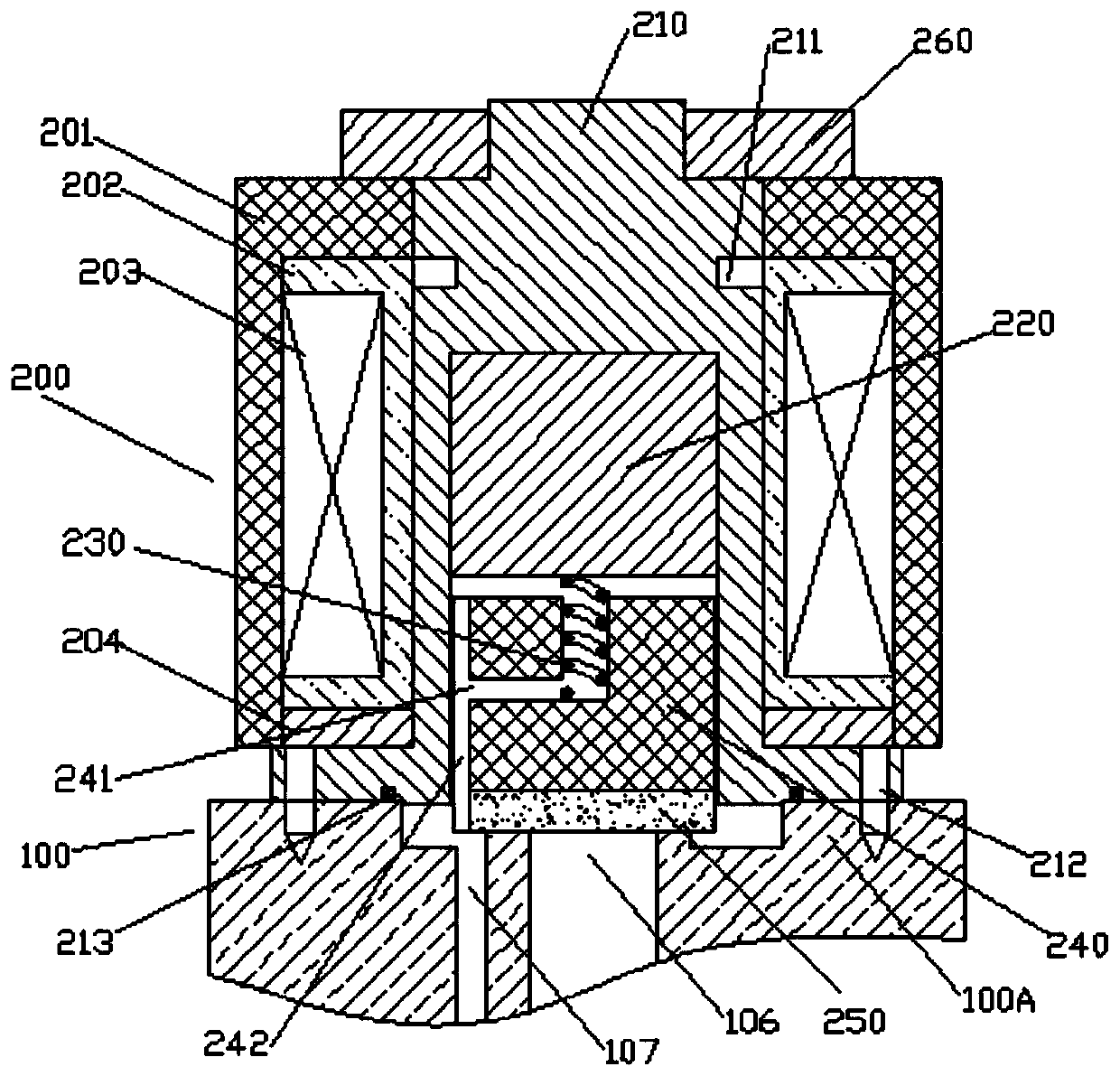

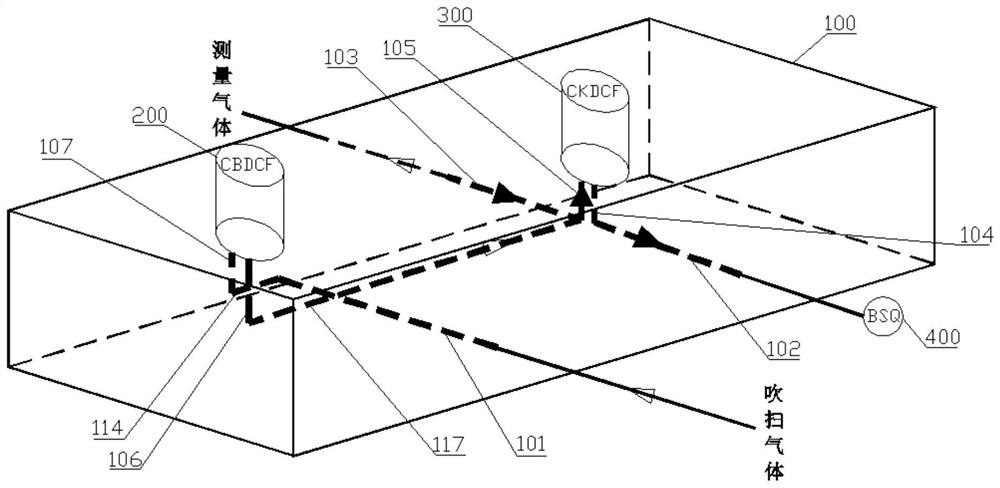

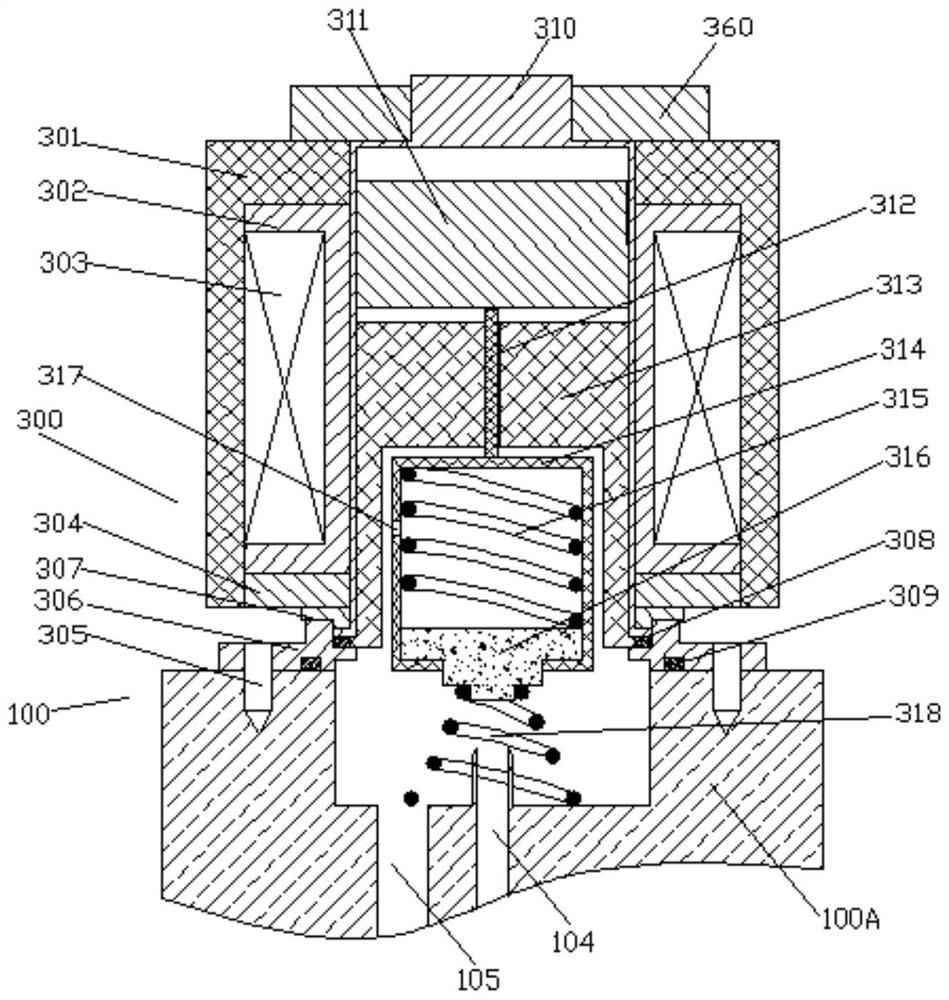

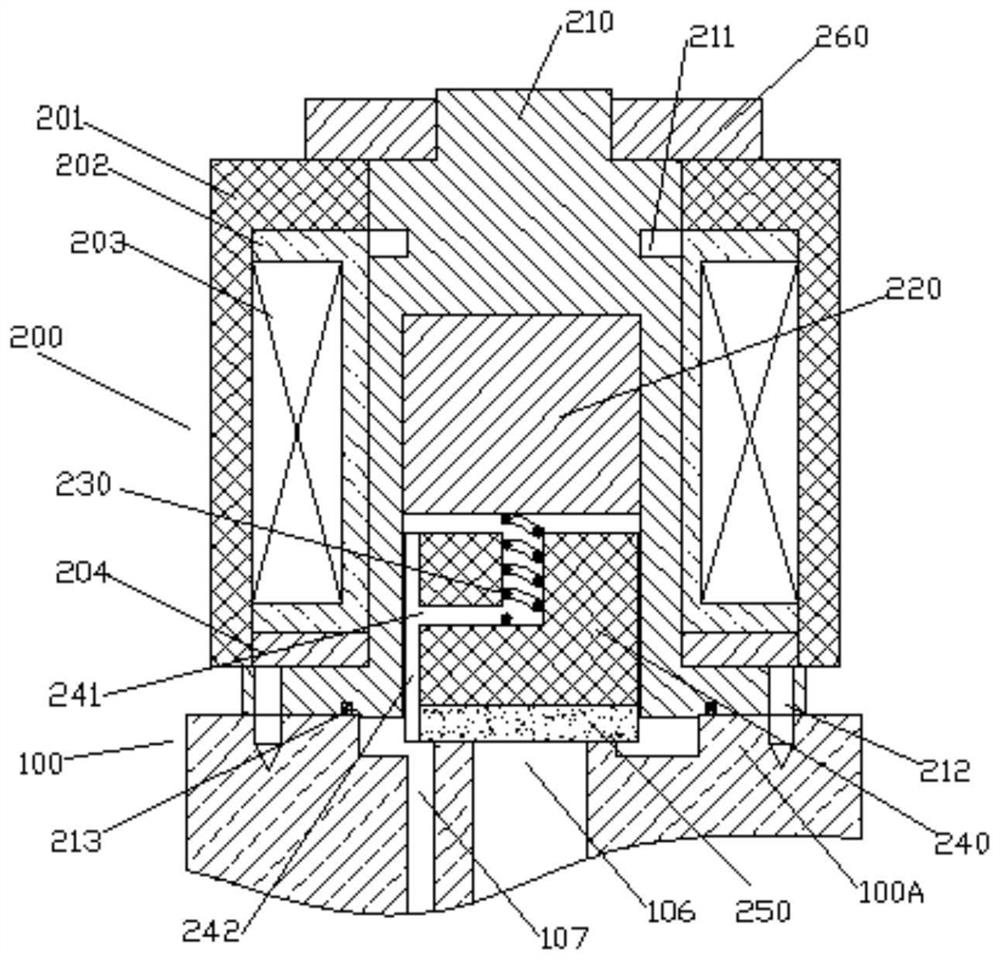

Back-purging device for measuring gas pipeline

ActiveCN111520611AReliable isolation and sealingMake sure to openOperating means/releasing devices for valvesPipeline systemsEngineeringMechanical engineering

The invention provides a back-purging device for a measuring gas pipeline. A normally-open electromagnetic valve with the diameter of a measuring gas butt-joint inlet larger than that of a measuring gas butt-joint outlet of the measuring gas butt-joint inlet and a normally-closed electromagnetic valve with the large drift diameter design of a purging gas inlet pipeline and the small drift diameterdesign of a purging gas outlet pipeline are mainly adopted, and meanwhile the fact that the pressure (1MPa or below) of purging gas is far larger than the pressure (8KPa or below) of measuring gas isingeniously utilized; reliable isolation and sealing of the normally-closed electromagnetic valve on the measuring gas in the measuring gas pipeline are achieved through the powerful pressure effectof the purging gas in the purging gas inlet pipeline in the normal measuring state, and reliable isolation and sealing of the normally-open electromagnetic valve on the measuring gas in the measuringgas outlet pipeline are achieved through the powerful pressure effect of the purging gas entering the measuring gas inlet pipeline in the purging measuring state; and the normally-closed electromagnetic valve is instantly opened, and the gas measuring work of the device in the normal measuring state and the purging measuring state is safe and reliable.

Owner:XIAN JINGZHAO POWER TECH

Repair technology and preparation technology of tubular PERC solar cell

ActiveCN107331730AEL yield improvementIncrease power generationFinal product manufactureSemiconductor/solid-state device manufacturingNitrogenRoom temperature

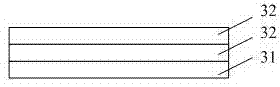

The invention discloses repair technology of a tubular PERC solar cell. The repair technology is set after annealing of a silicon wafer and before film coating of a back face of the silicon wafer. The repair technology comprises the following steps: (1) a semi-finished silicon wafer which stays over 4 hours after the annealing and before the film coating is placed into a repair furnace, nitrogen having a flow rate of 5-10slm is introduced into the repair furnace to achieve self-cleaning, and inlet time of the nitrogen is 1-5min; (2) nitrogen having a flow rate of 5-20slm is introduced to blow and sweep dust on the silicon wafer; (3) temperature of the repair furnace is raised from room temperature to 500-650 DEG C, and nitrogen having a flow rate of 1-5slm is introduced at the same time; and (4) the temperature of the repair furnace is kept at 500-650 DEG C for 5-30min, and nitrogen having a flow rate of 5-20slm is introduced at the same time. Correspondingly, the invention further discloses a preparation technology of the tubular PERC solar cell. Through adoption of the repair technology and the preparation technology, the problem of efficiency reduction brought by too long semi-finished product stay time is solved, and the EL yield rate is improved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +1

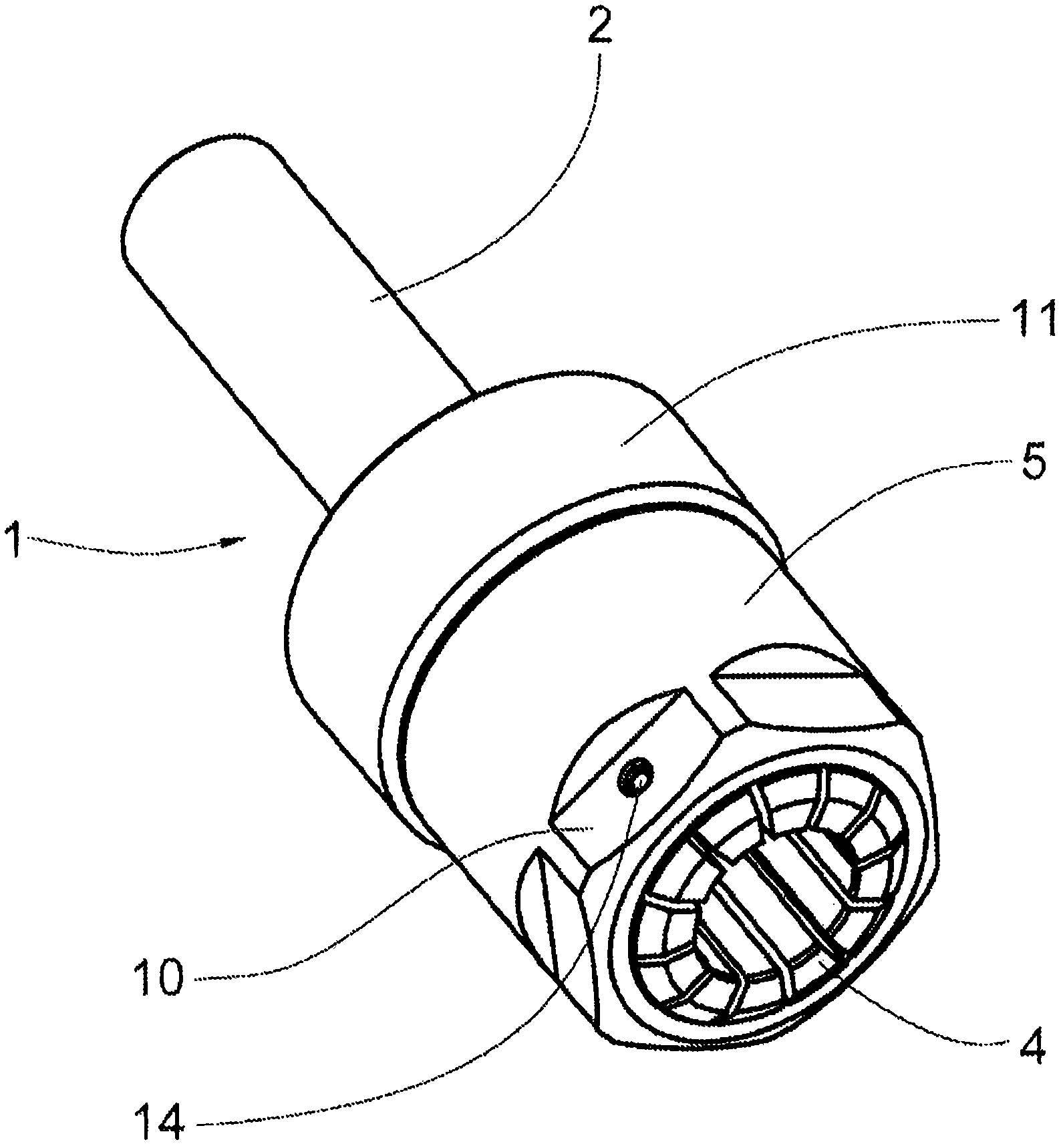

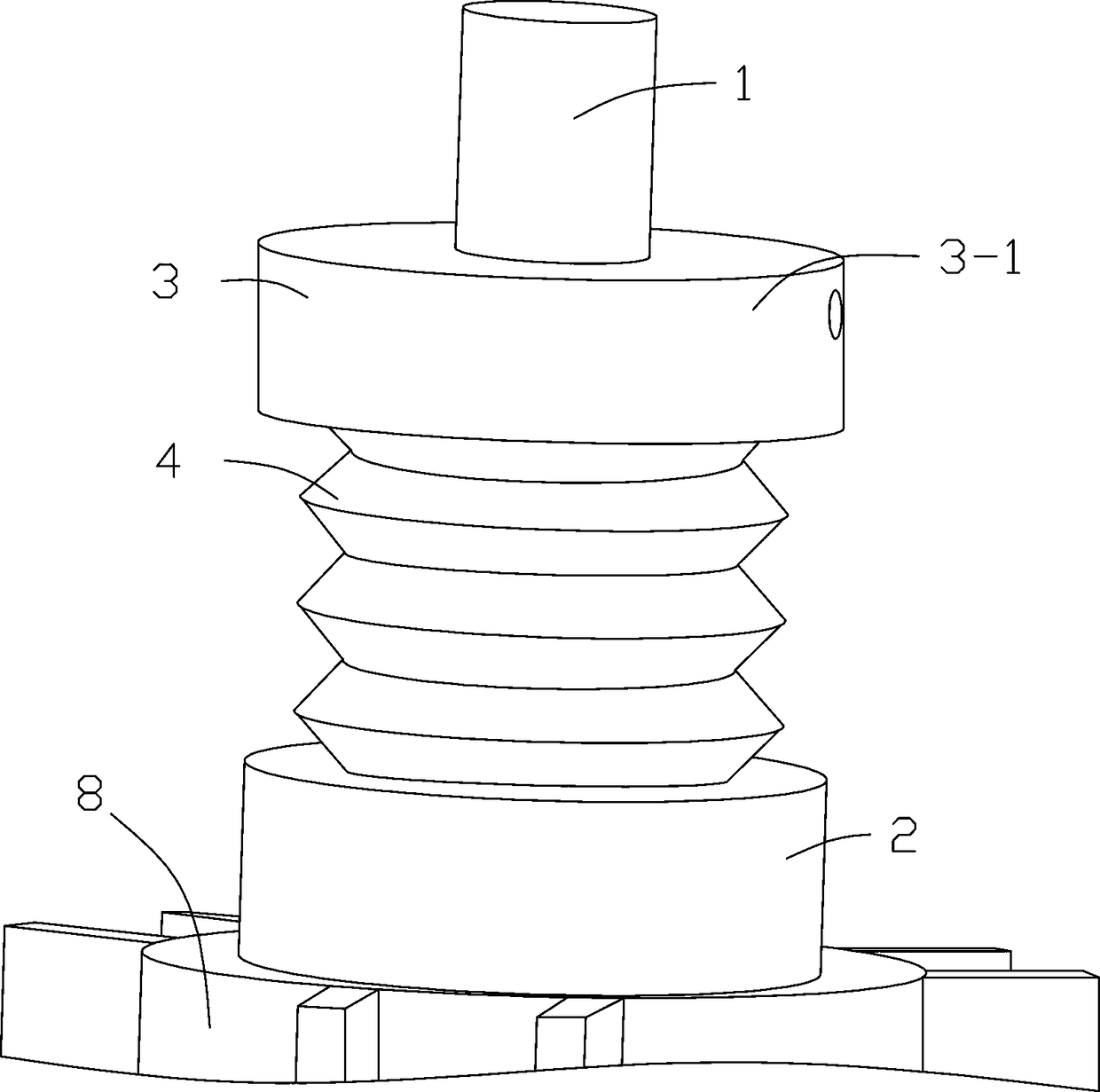

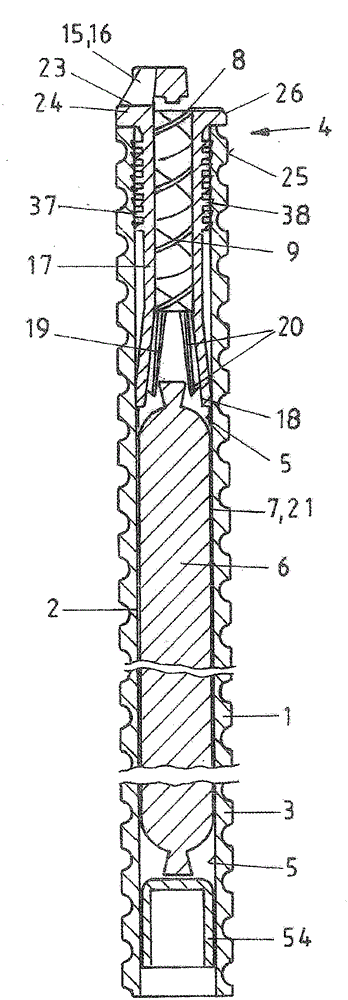

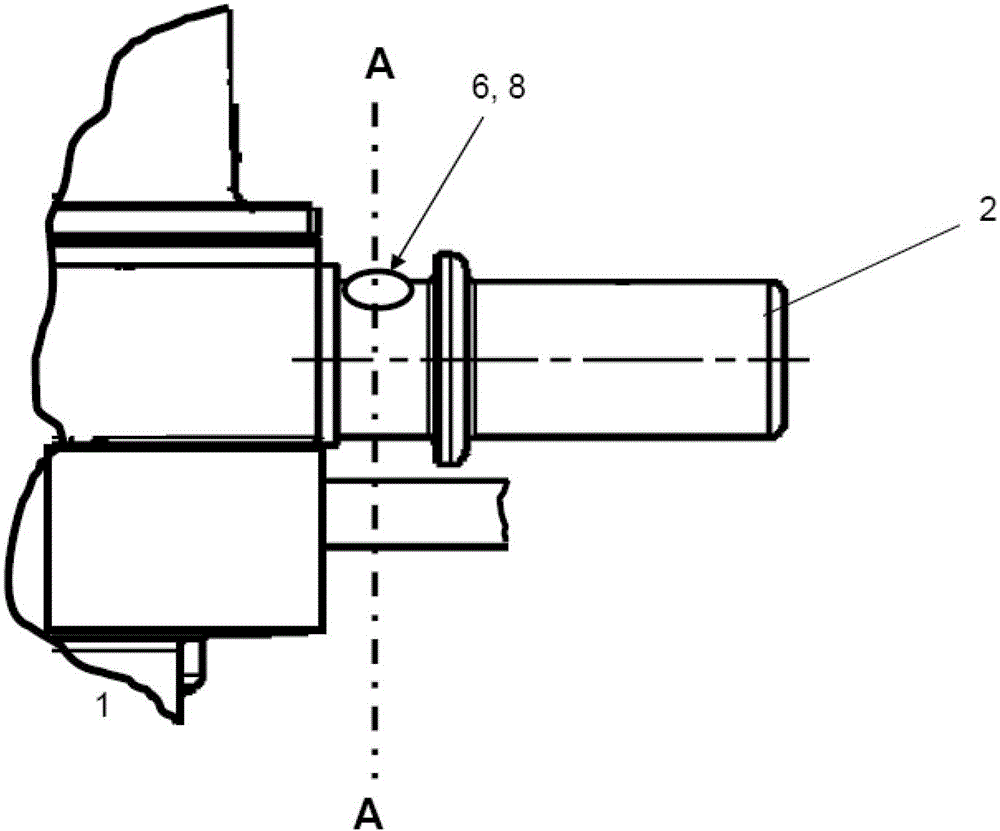

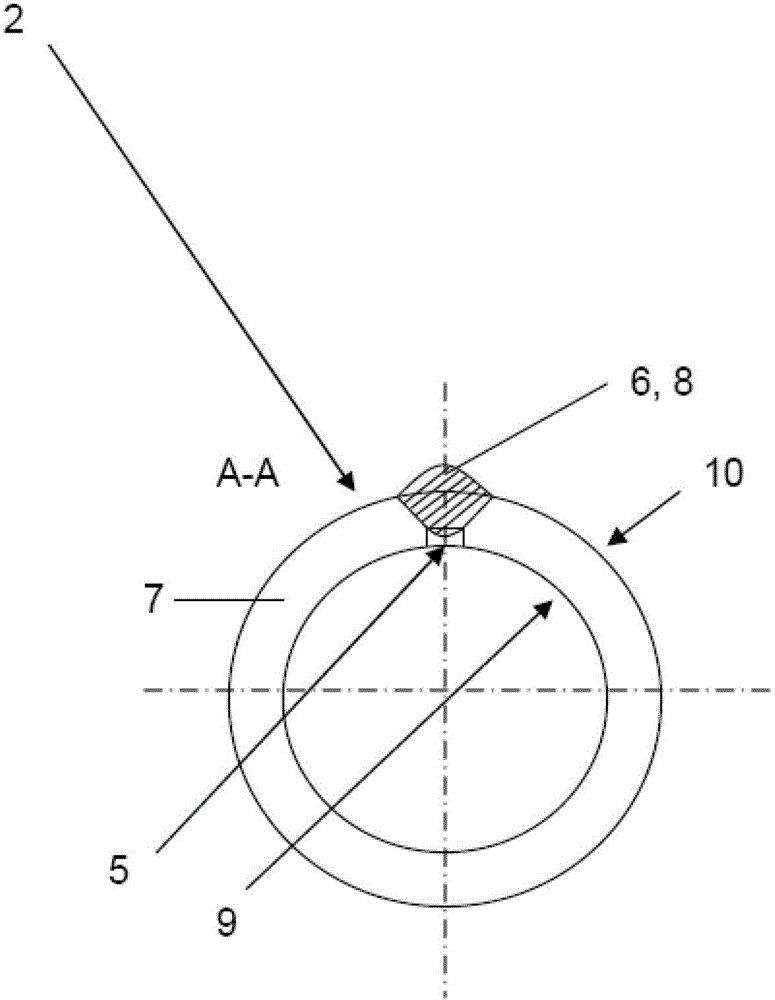

Collet chuck

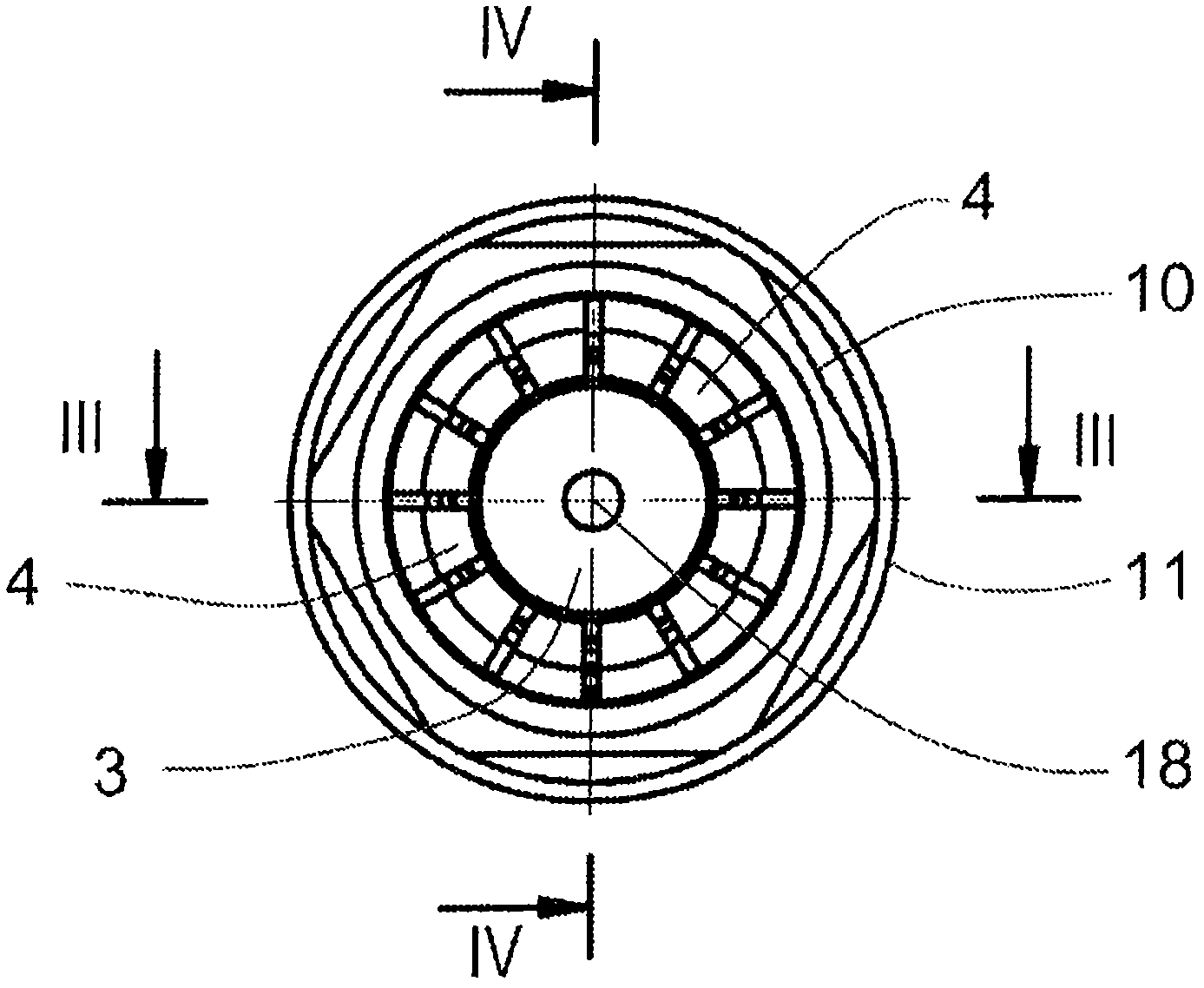

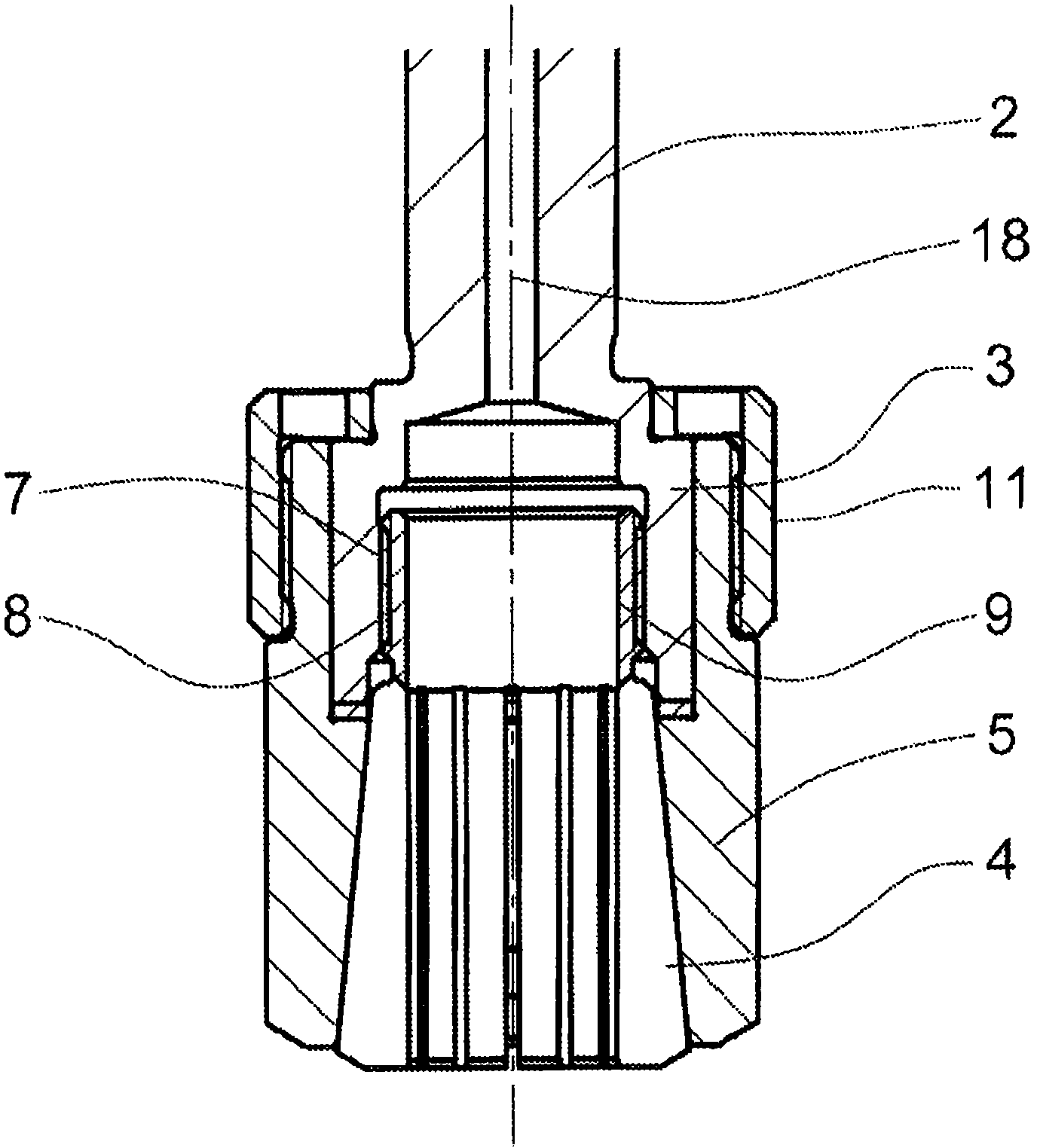

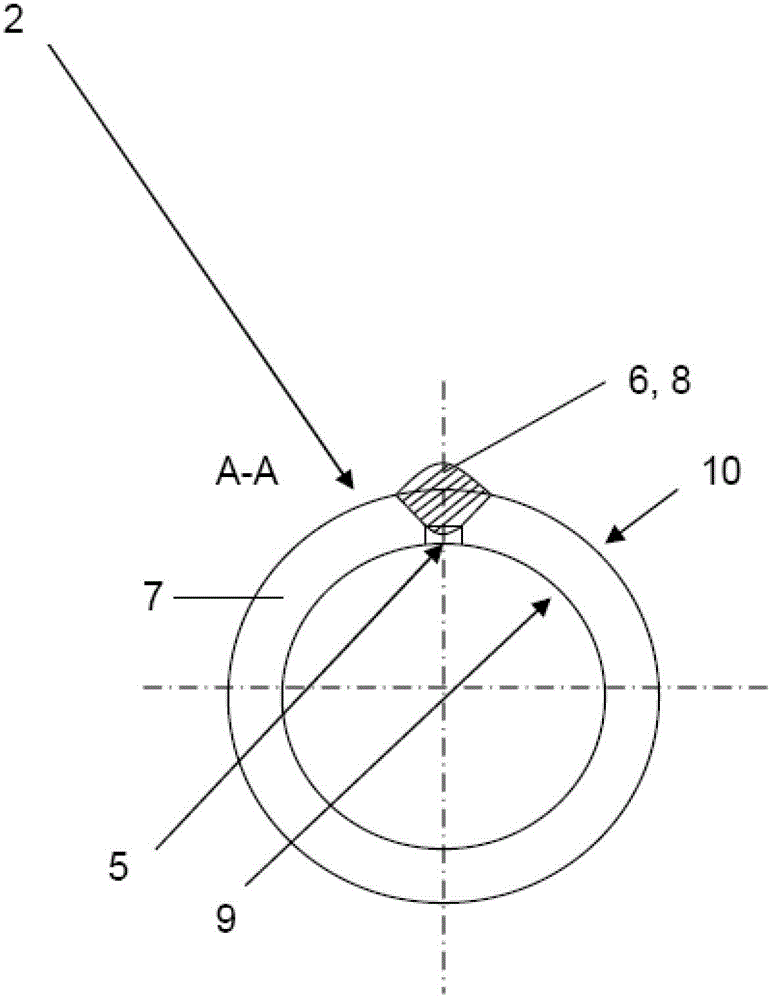

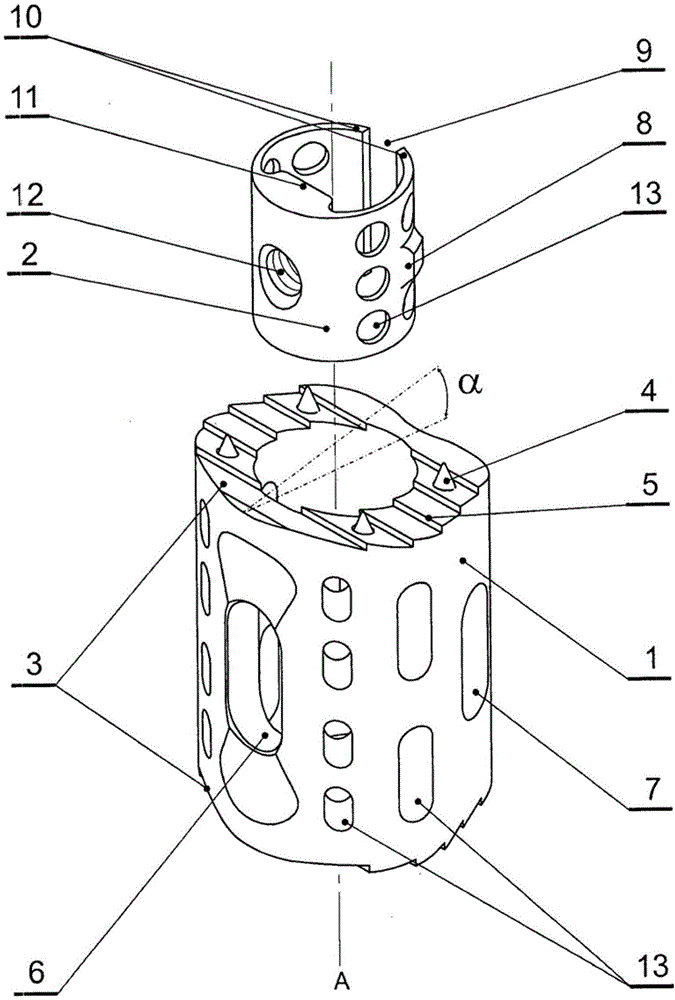

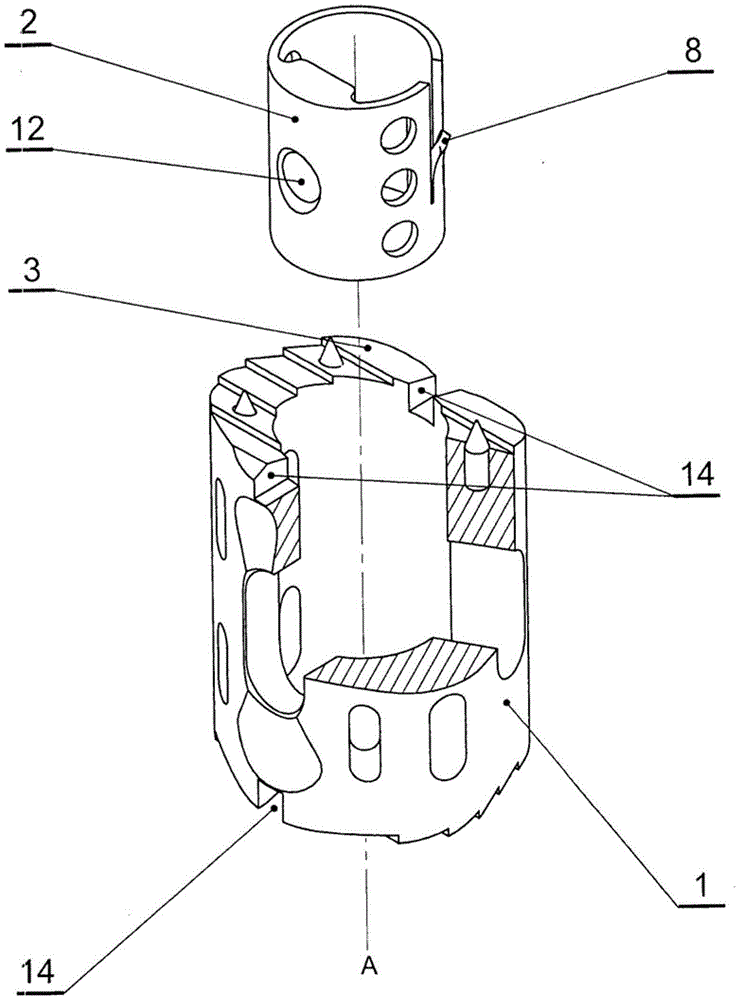

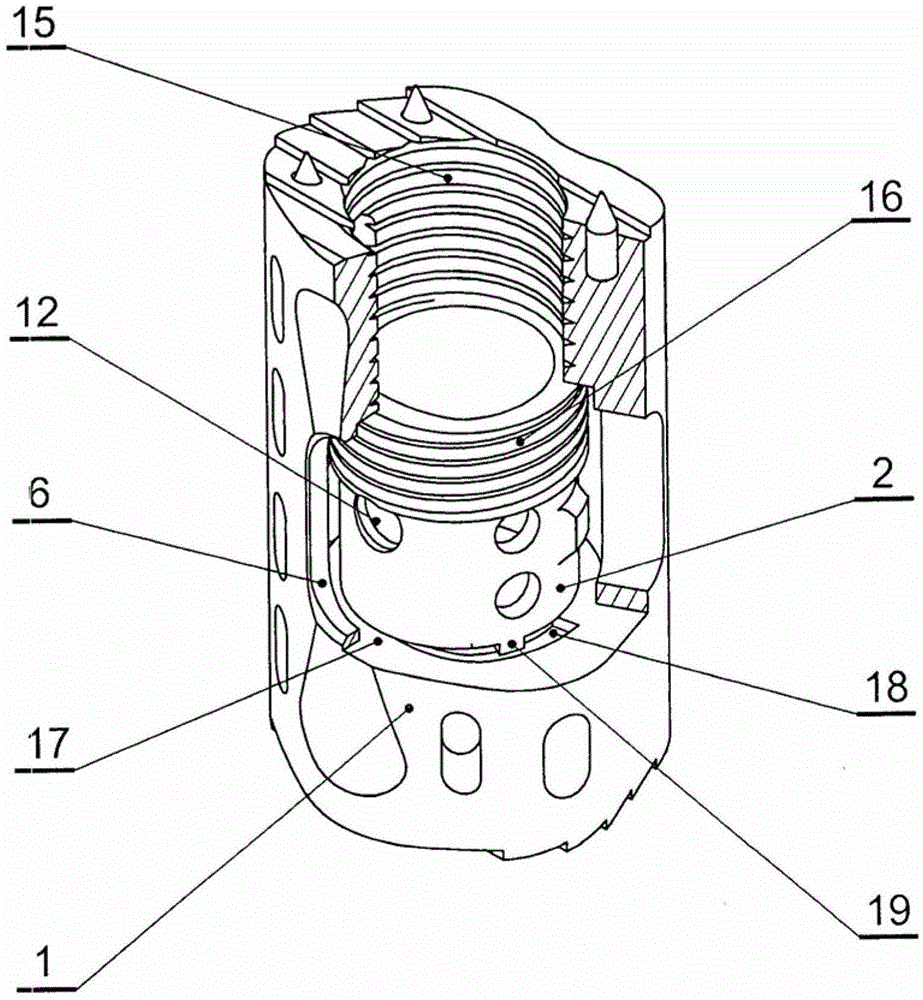

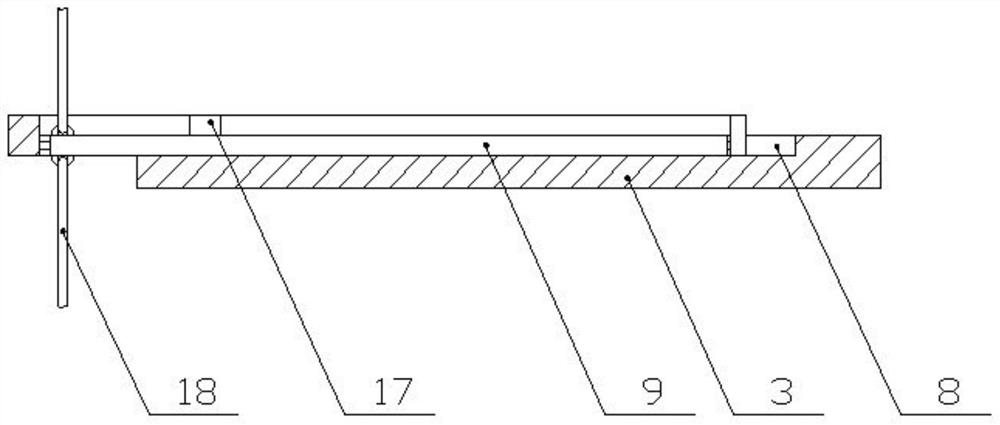

InactiveCN102655969ATo achieve axial adjustmentLarge clamping forceSleeve/socket jointsChucksEngineeringCollet

The invention relates to a collet chuck (1), comprising a chuck body (3) that is or can be connected in a rotationally fixed manner to a drive spindle (2), a collet (4), and a conical sleeve (5) associated with the chuck body (3). The conical sleeve (5) is arranged on the chuck body (3) in such a way that the conical sleeve cannot slide axially, and a threaded connection (6) is effective between the chuck body (3) and the collet (4).

Owner:ROHM CO LTD

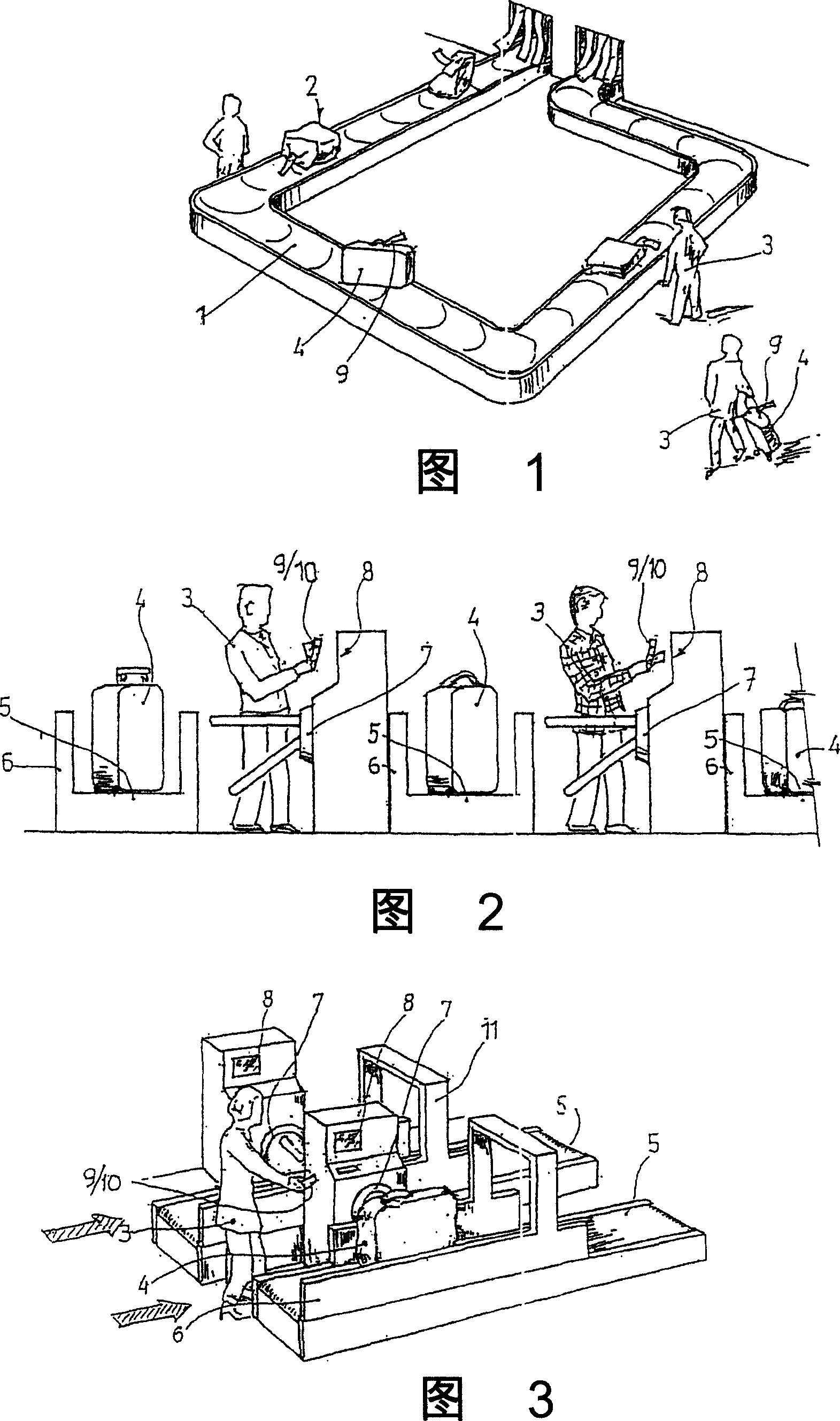

Control device for exiting of travelers with their luggage

InactiveCN1996398AGuaranteed normal startupGuaranteed reliabilitySensing record carriersIndividual entry/exit registersBarcodeEngineering

The present invention discloses a control device of the exit which is used for the passenger carrying luggage at the places such as airport and the like, the control device comprises a bar code reading unit (8) which functions when the identification label (9) of the hand luggage (4) and the label receipt (10) held by the passenger are read, and at the same time the forward movement of the luggage (4) placed on the conveying belt (5) to the safety detecting arched door (4) and the turnstile or obstacle (7) for the passing of the passenger are actuated. When the two bar codes are compared to same the instruction conveying belt (5) is moved forwards by a step by providing one-digit additional safety code, and at the same time the unit instruction is read to allow the passing of the passenger. The bar code reading unit (8) can continuously read for the requested times when the bar code is checked, and also the subsequent a plurality of steps are moved forwards according to the number of the portable luggage (4). The passenger inserts the labels (9) and (10) into the reading device (8) and when one or several luggage of the control device are received one in the two sides is conveyed immediately.

Owner:曼努埃尔·费德里科·埃尔南德斯·莫伊西

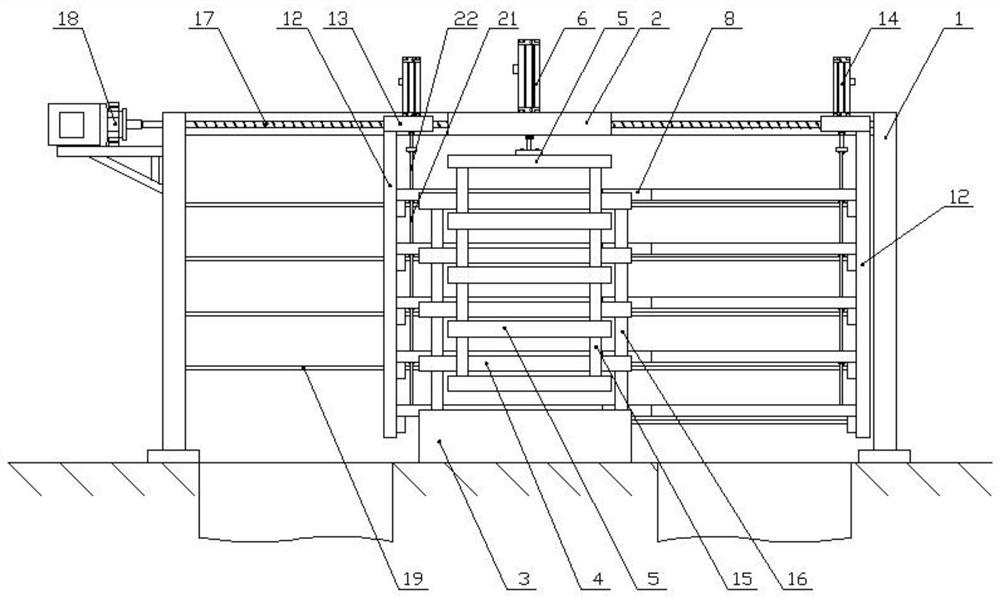

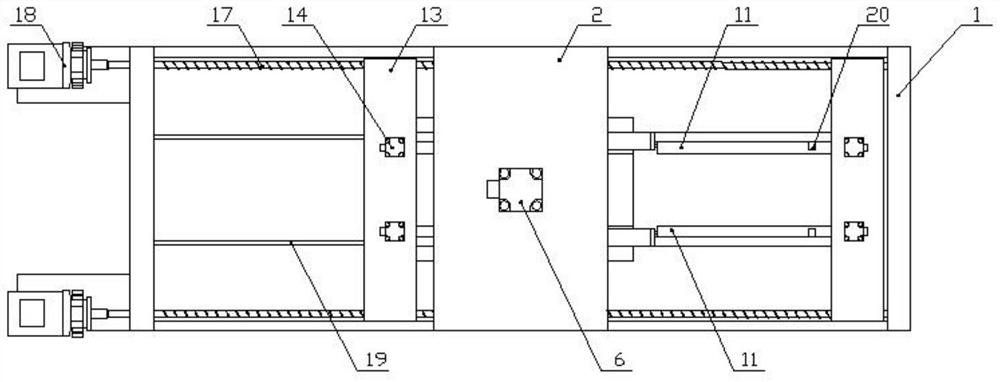

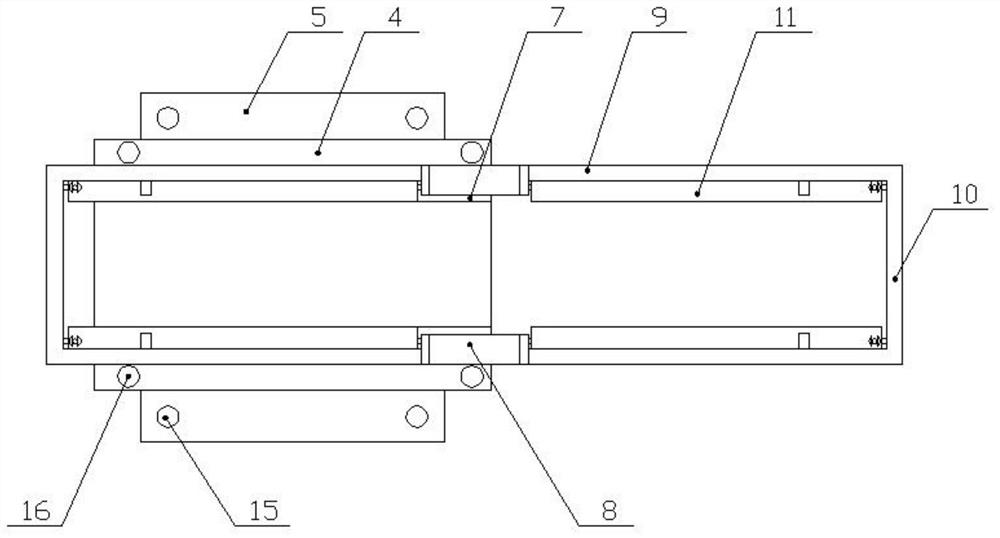

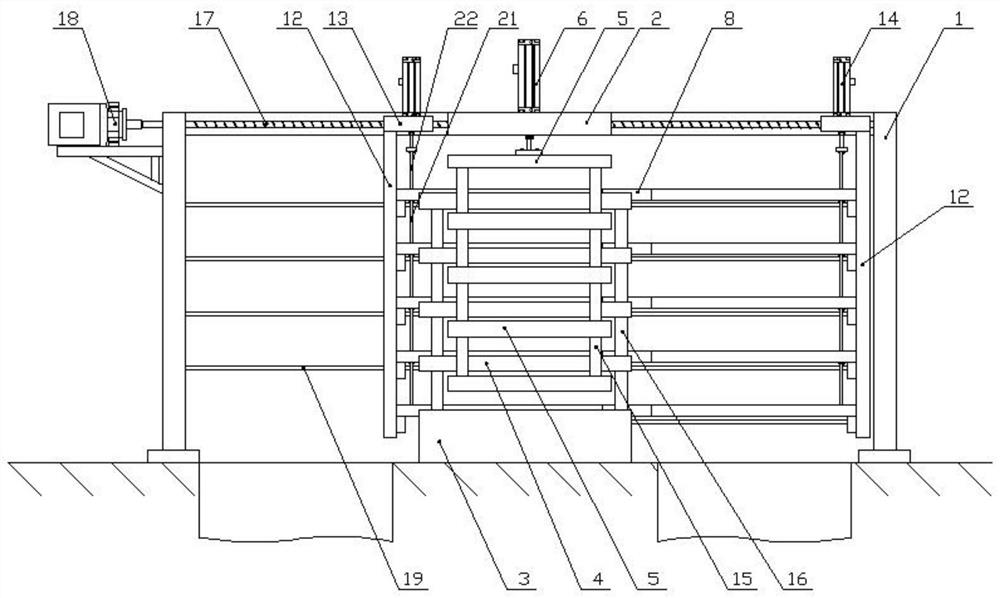

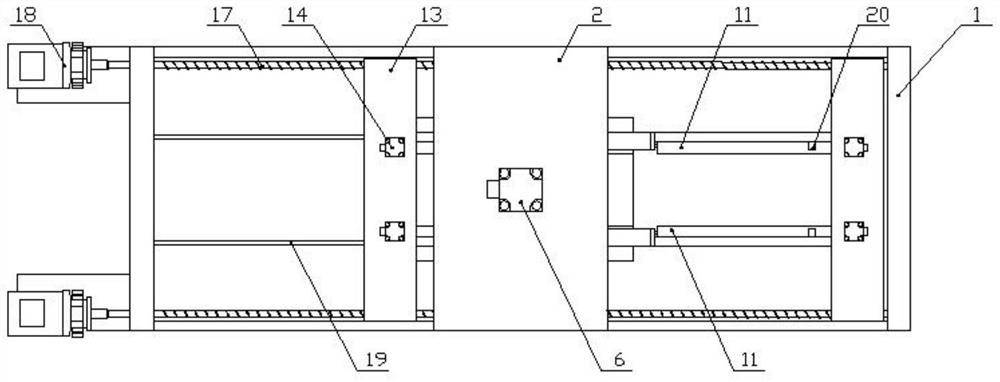

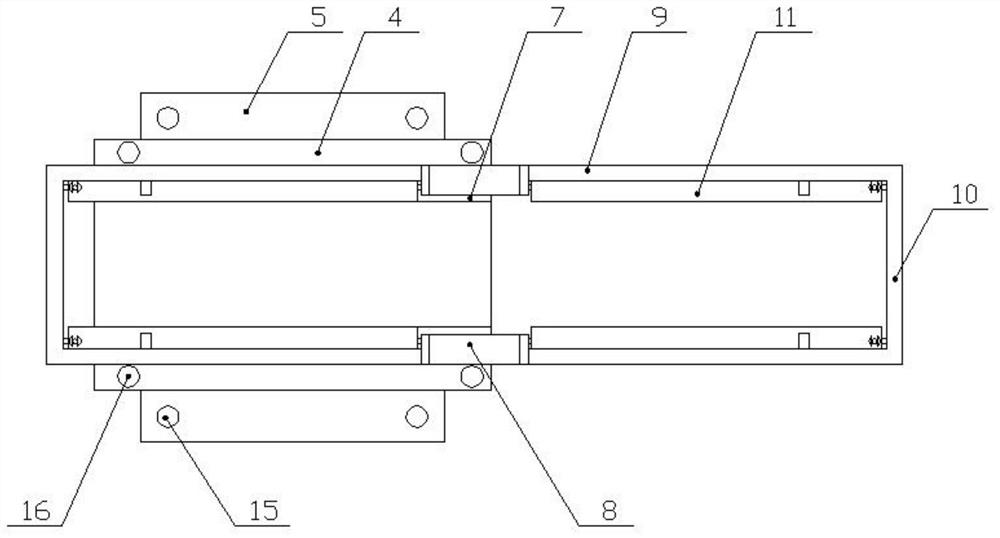

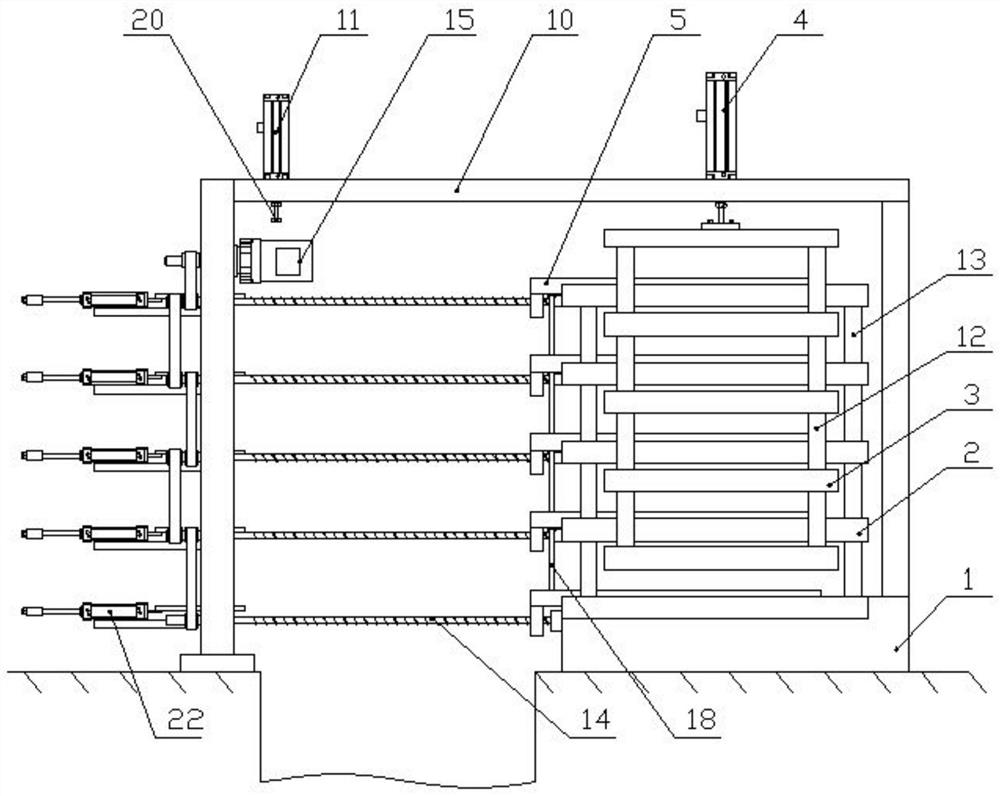

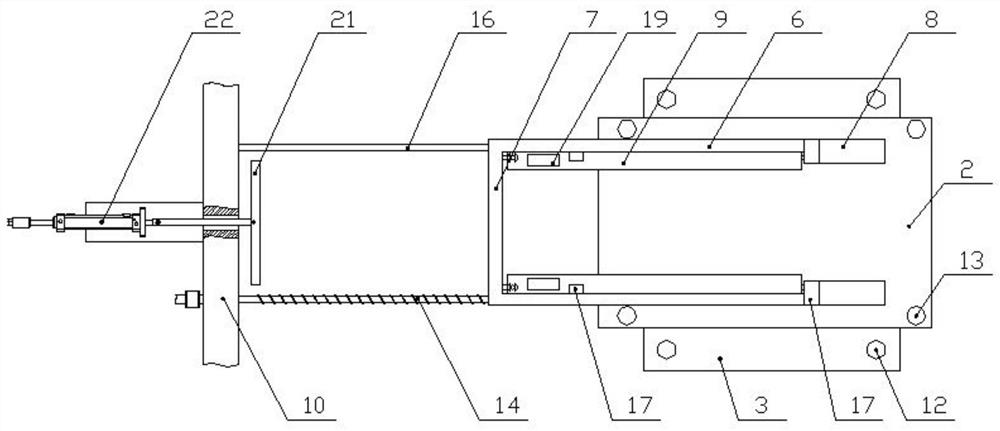

Reciprocating plywood production device

ActiveCN112077955AAvoid burnsReduced risk of burnsPlywood pressesVeneer pressesStructural engineeringMechanical engineering

The invention discloses a reciprocating plywood production device, and belongs to the field of plywood processing. The reciprocating plywood production device comprises a machine frame, a top wall isarranged in the middle of the upper end of the machine frame, a base is arranged at the lower end of the machine frame and below the top wall, a lower hot pressing plate is arranged at the upper end of the base, and an upper hot pressing plate is arranged on the upper part of the lower hot pressing plate. The upper hot pressing plate ascends and descends in a reciprocating mode under the action ofa hot pressing driving device, sliding grooves with the two communicating ends are formed in the upper end face of the lower hot pressing plate at intervals, connecting parts are movably arranged inthe sliding grooves, plate blank containing frames are oppositely arranged at the two ends of the connecting parts, the plate blank containing frames include movably arranged object carrying plates, and the object carrying plates on the two sides are arranged oppositely. The plate blank containing frames are connected with sliding parts through connecting plates, the sliding parts are arranged atthe upper end of the machine frame and slide in a reciprocating mode in the length direction of the sliding grooves, and the sliding parts is provided with discharging driving devices for pushing theobject carrying plates to turn over downwards. According to the reciprocating plywood production device, and rough boards can be conveniently taken out of hot pressing equipment.

Owner:湖南闽新新材料股份有限公司

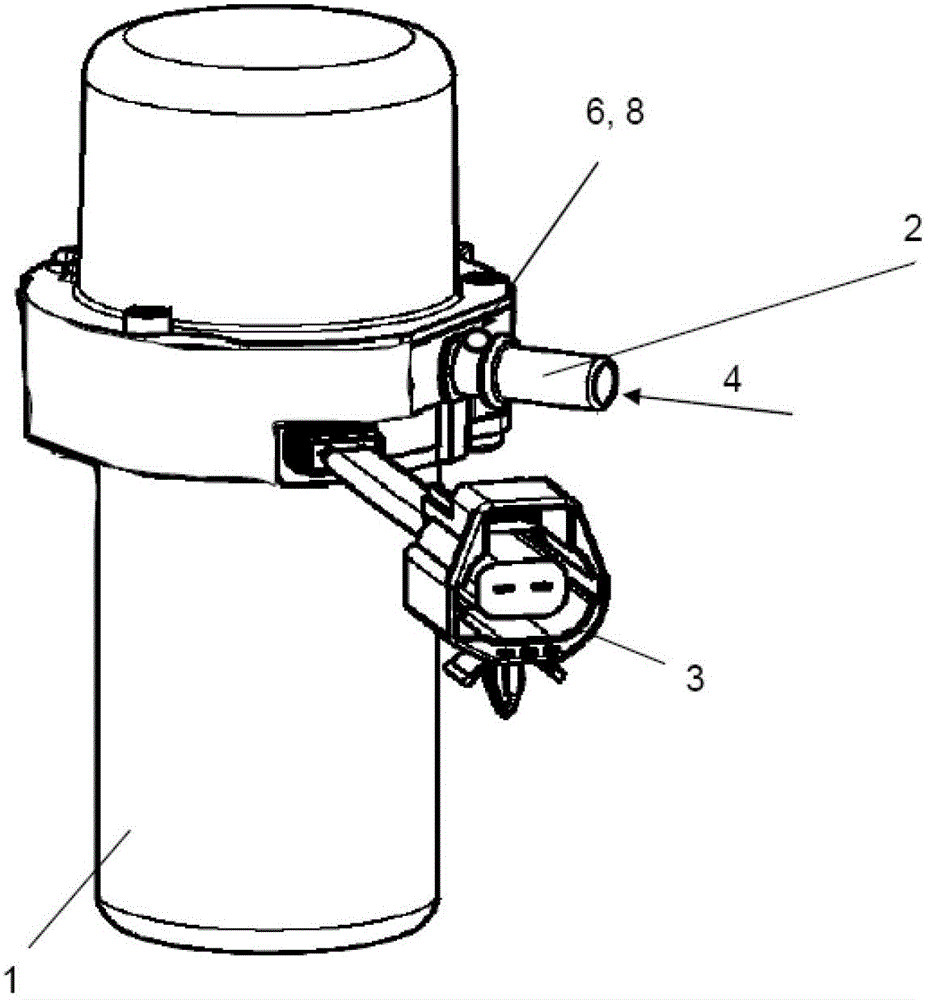

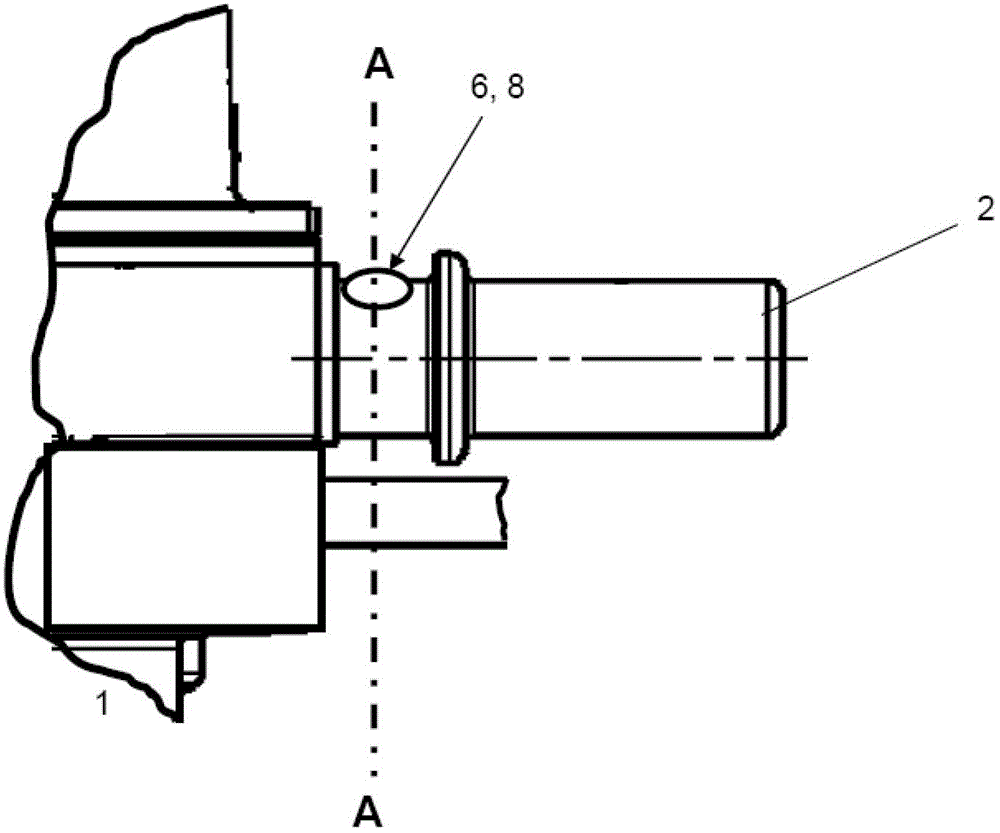

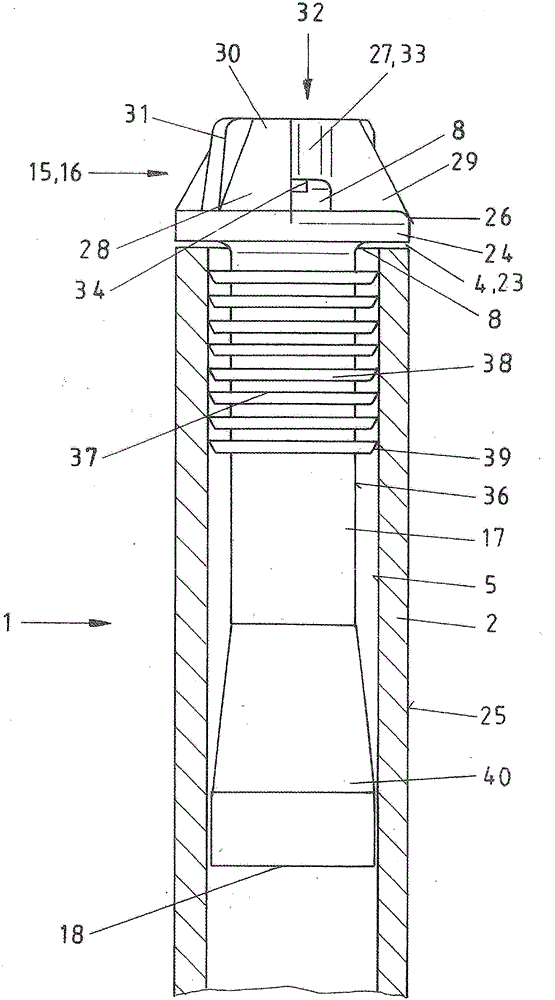

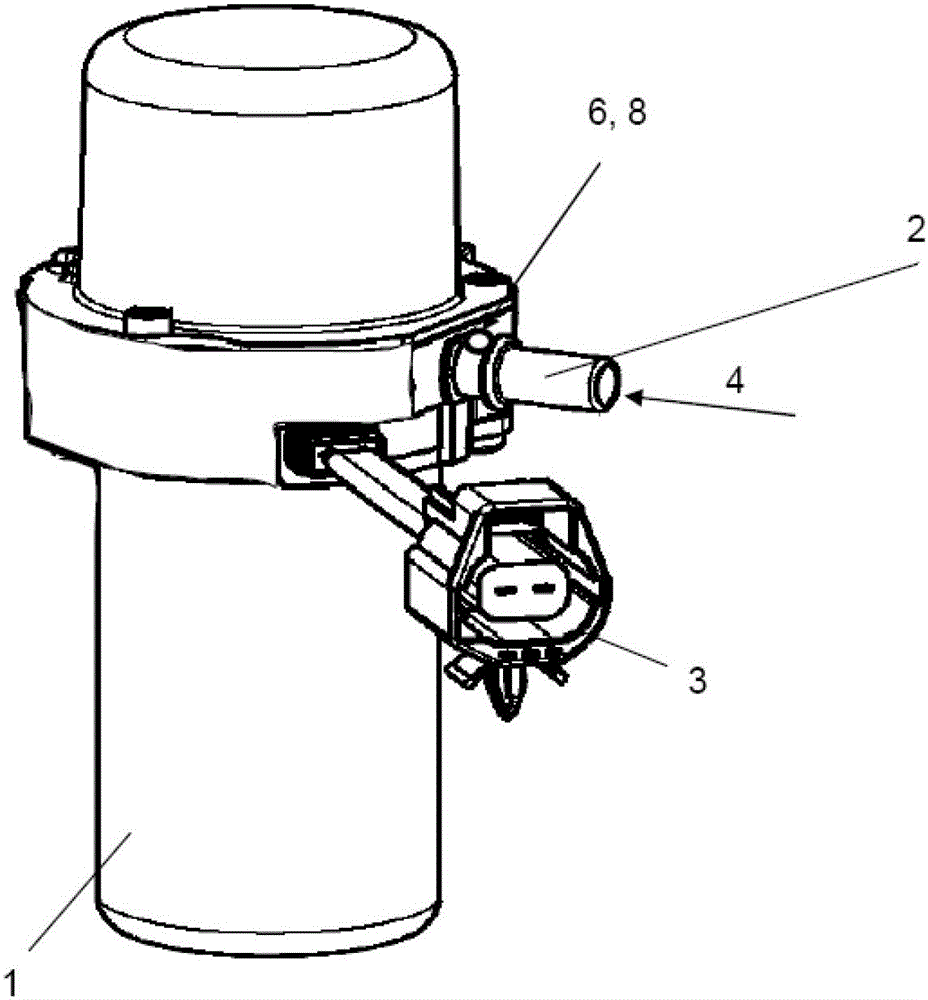

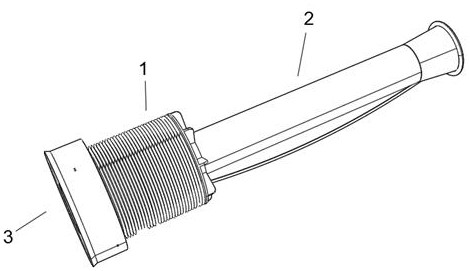

Electric vacuum pump for motor vehicle

ActiveCN102865229AMake sure to openEffective "secondary" airflowRotary piston pumpsRotary piston liquid enginesEngineeringMotorized vehicle

The present invention relates to a vacuum pump (1), wherein the inlet connection member (2) of the vacuum pump is connected with a unit generating a negative pressure through a connection pipe line, between the vacuum pump (1) and the unit there is provided a non-return valve, and the vacuum pump (1) is provided with a monitoring unit. In order to prevent the vacuum pump from being overheated with no need for continuous operation, the lower portion of the non-return valve is provided with a hole (5), and the hole (5) is enclosed when used for meltable materials (6, 8) fused at a pre-defined melt temperature and for sublimable materials (6, 8) sublimated at a pre-defined sublimating temperature. The originally-enclosed hole (5) is opened through the melted or sublimated meltable or sublimable materials, thereby being convenient for the vacuum pump (1) to inhale fresh air for cooling.

Owner:FORD GLOBAL TECH LLC

Prosthesis for spinal column, instrument for its guiding and method for implantation thereof

InactiveCN102869322AReduce the level of complexityShort durationJoint implantsSpinal implantsSpinal columnIntervertebral space

Owner:LFC Z O O

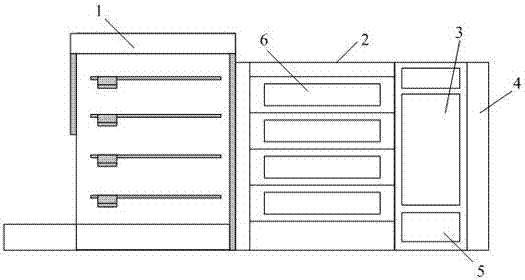

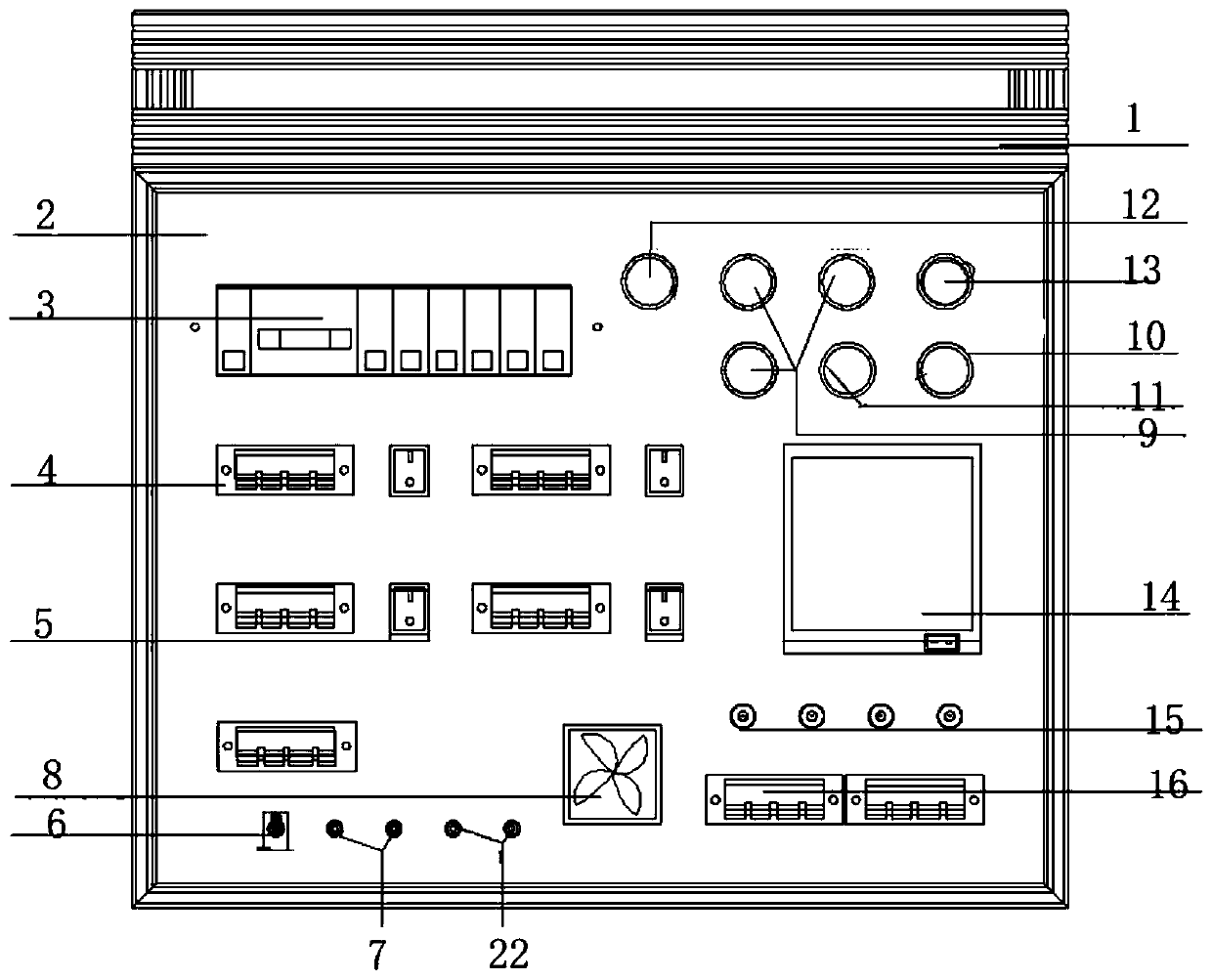

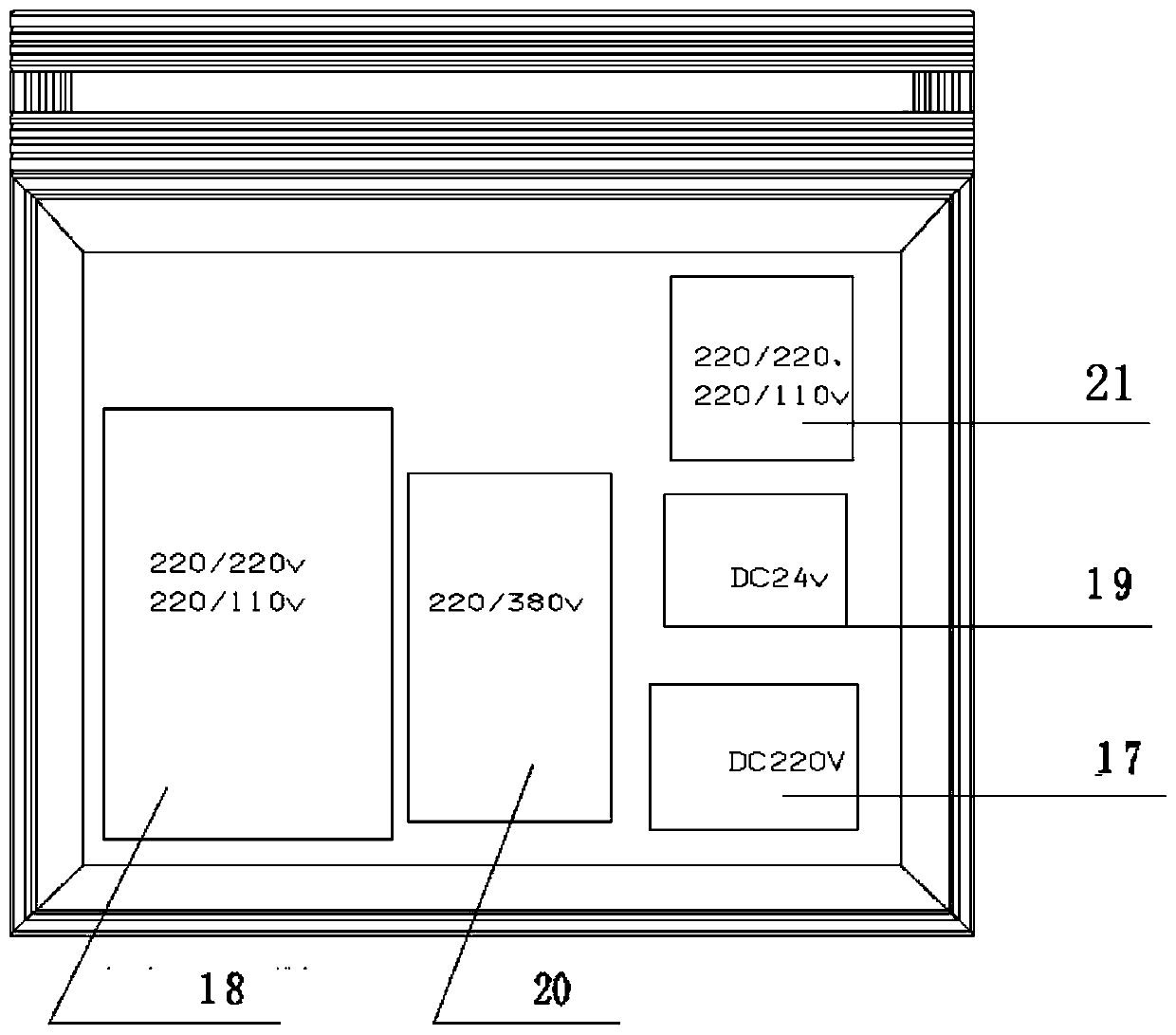

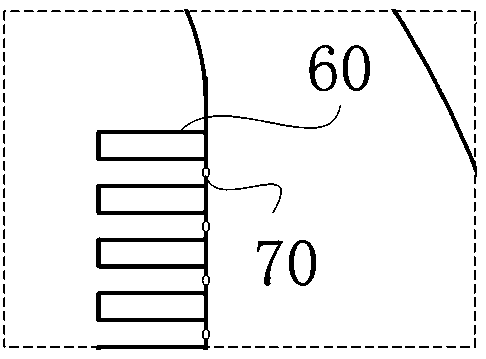

Multi-functional power supply device for railway signal test

PendingCN109698609AAvoid failureReduce incomplete conductionConversion constructional detailsAviationTransformer

The invention discloses a multi-functional power supply device for a railway signal test. The device comprises a box body, a control panel is attached on the surface of the box body, electrical equipment is attached in the box body, the electric equipment comprises a DC 220V turnout power supply module, a 25HZ track circuit power supply module, a DC 24V relay power module, a 220V to 380V invertermodule and a transformer. The control panel is provided with eight sets of circuit breakers, five wiring terminal blocks, four ship-type switches, one power switch button sub switch, two AC220V wiringterminal columns, a cooling fan, three digital display indicators, a digital display ammeter, a digital display voltmeter, a three-phase AC power start button, a power input three-core aviation plug,a 25HZ track circuit phase tester, four buttons sub switches, and two 4-hole track wiring terminals. By applying the multi-functional power supply device, the construction risk coefficient is greatlyreduced, the engineering cost is reduced, and the driving safety is improved.

Owner:中铁武汉电气化局集团上海电气有限公司

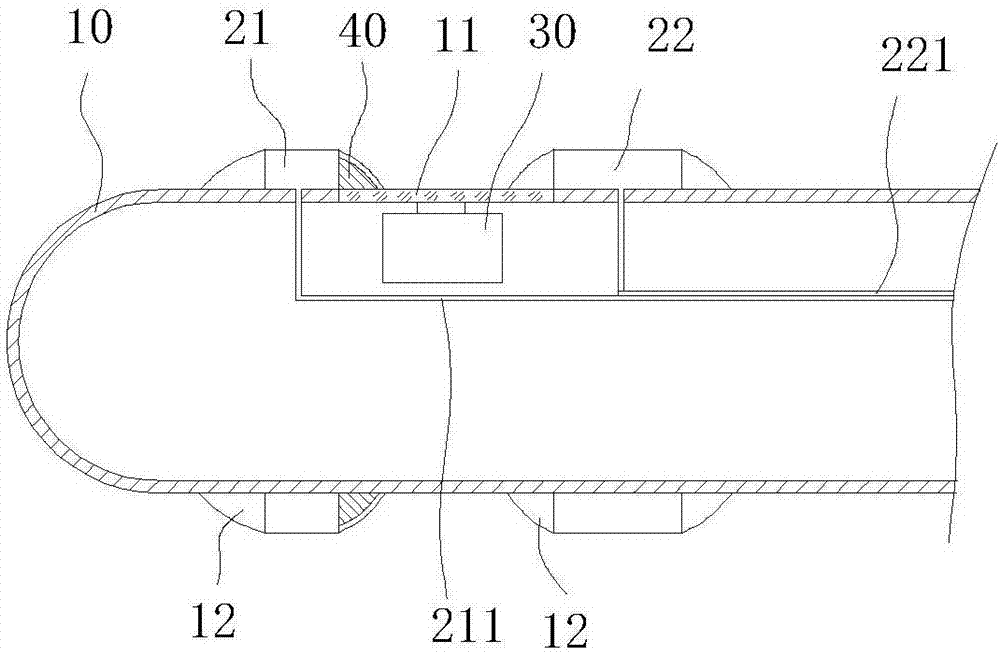

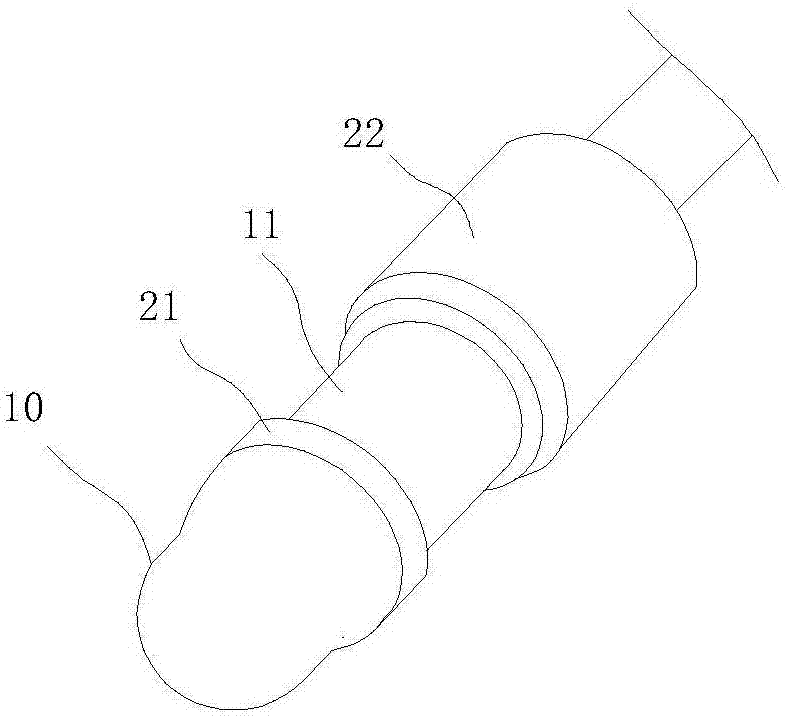

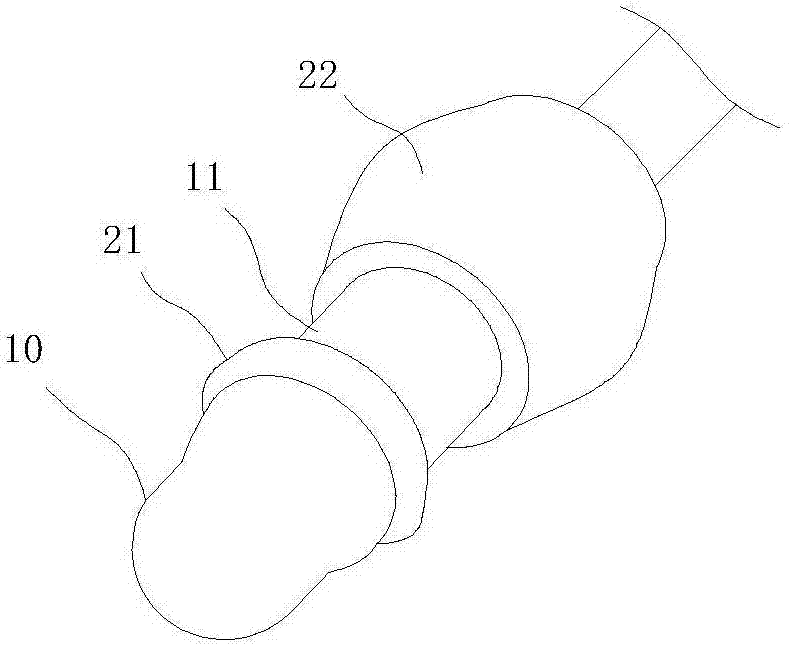

Anorectal detecting probe

PendingCN107411698AIncrease brightnessMake sure to openSurgeryMedical devicesSurgeryIntestino-intestinal

The invention provides an anorectal detecting probe. The anorectal detecting probe comprises a shell, and the shell is provided with an annular first gas bag and an annular second gas bag which are arranged in the radial direction of the shell in a protruding mode; the first gas bag and the second gas bag are connected with a gas source, the first gas bag and the second gas bag are arranged at intervals and a shell body between the first gas bag and the second gas bag is a transparent shell; a camera head of a camera points to the transparent shell, and a light source is further arranged between the first gas bag and the second gas bag; the end of the shell is placed into an anus of a patient, the probe enters intestine, and appropriate gas is slowly injected into the first gas bag and the second gas bag according to the actual situation in the intestine of the patient, outer bag walls of the first gas bag and the second gas bag protrude outward and abut against the inner wall of the intestine, and it is ensured that the anus and the intestine can be distracted; and brightness between the first gas bag and the second gas bag is improved by the light source, so that the camera can shoot images of the inner wall of the intestine clearly.

Owner:SUZHOU L BIO BIOTECH

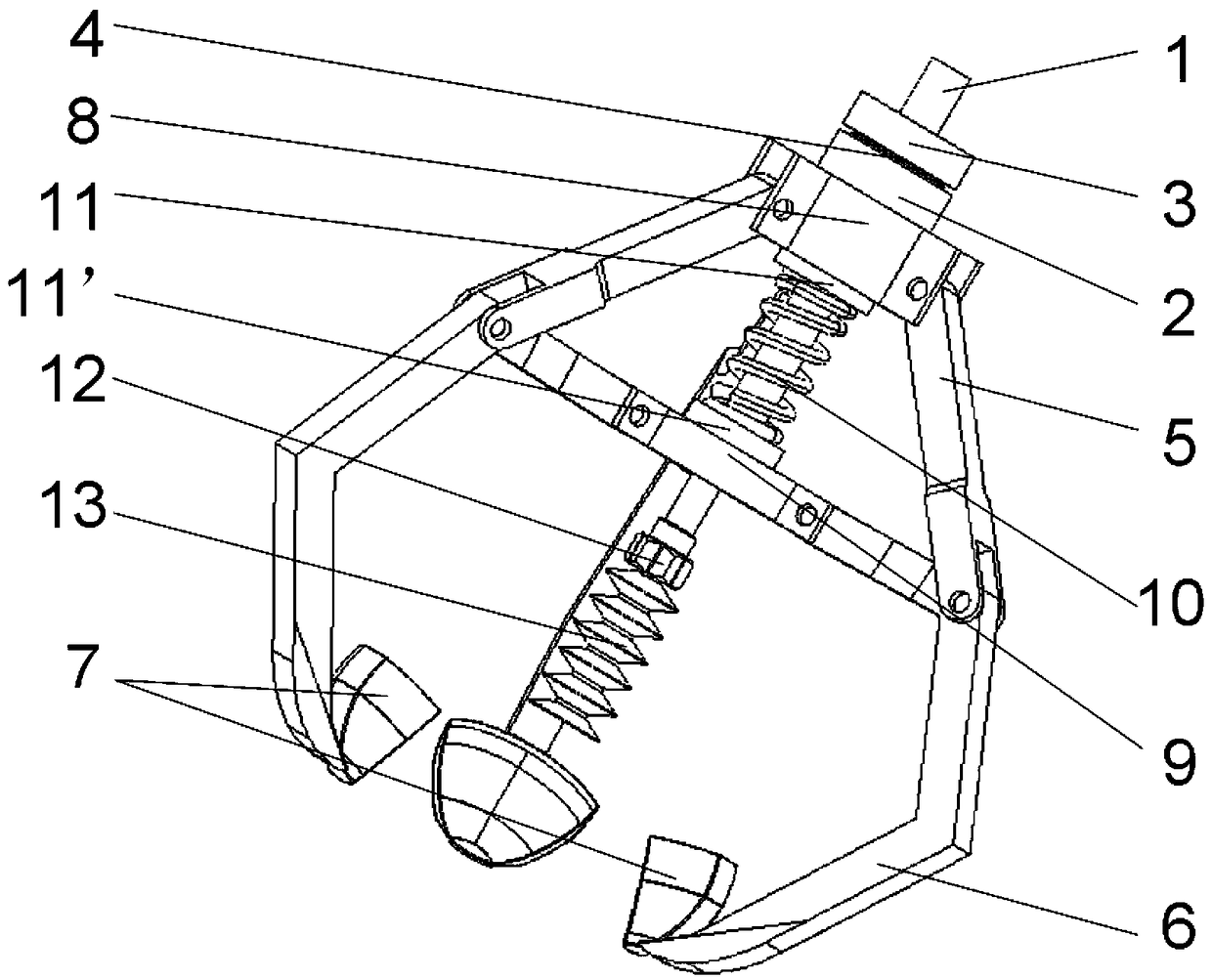

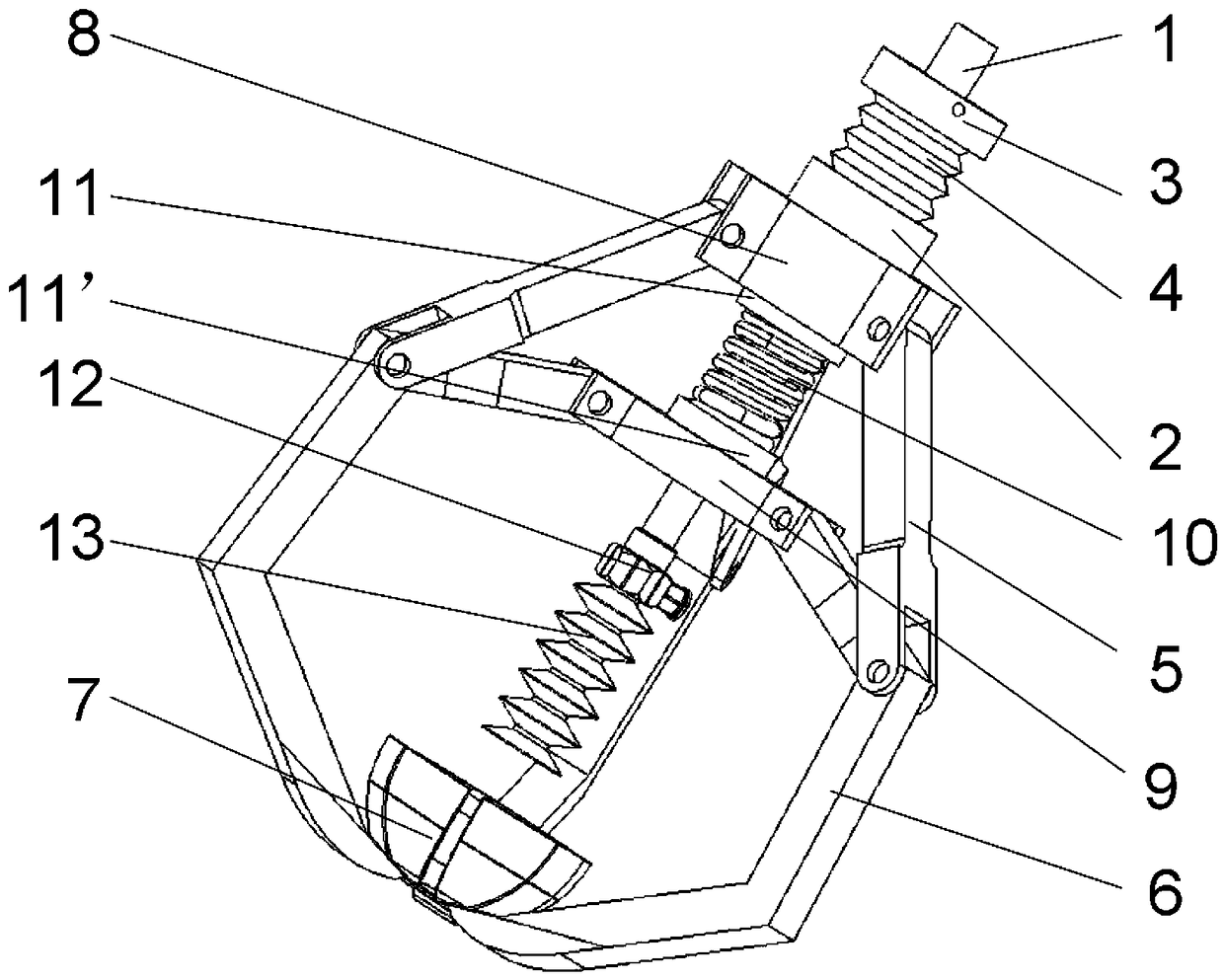

A Manipulator Suitable for Grabbing Poultry Eggs

ActiveCN105798941BMake sure to openMeet different work needsGripping headsBird housingsEngineeringAirbag

The invention discloses a manipulator suitable for bird egg grabbing. The manipulator comprises a guide rod; an airbag is coaxially mounted on the guide rod; the upper side of the airbag is connected with an airbag base; the lower side of the airbag makes contact with a slide block; a pressure spring is coaxially mounted with the guide rod, and is positioned below the slide block; a pull rod frame and a grabbing jaw frame are mounted on the guide rod; the pressure spring is positioned between the pull rod frame and the grabbing jaw frame; a pull rod is movably mounted between the pull rod frame and the grabbing jaw frame; a clamping jaw is movably mounted on the grabbing jaw frame; and an egg support is arranged at the tail end of the clamping jaw. In the manipulator suitable for bird egg grabbing, after bird eggs are grabbed by the clamping jaw, the bird eggs are synchronously absorbed by negative pressure, so that the flexible grabbing of the bird eggs is realized, the grabbing reliability is improved, and the positioning precision is reduced; and the manipulator suitable for bird egg grabbing is matched with a roaming egg picking robot to finish the egg picking work to realize automatic egg collection.

Owner:HUAZHONG AGRI UNIV

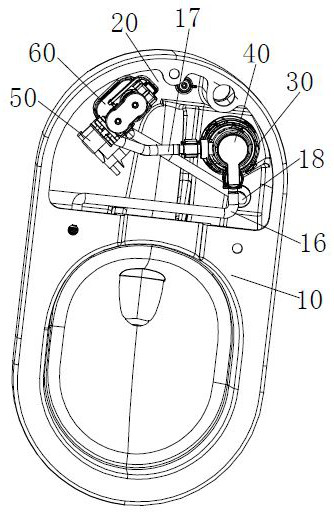

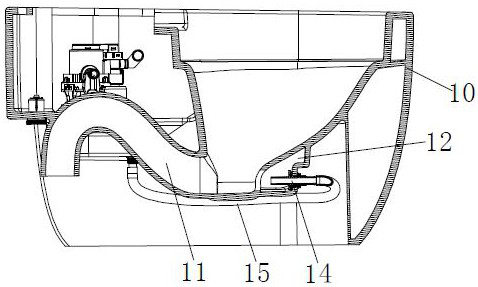

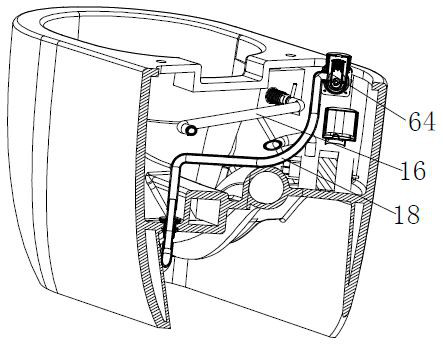

Efficient flushing pedestal pan

PendingCN114775746AImprove utilization efficiencyEasy flush controlFlushing devicesPipe waterWater tanks

The invention discloses an efficient flushing pedestal pan which comprises a pedestal pan body and a water tank, the pedestal pan body is provided with a blow-off pipeline, an injection pipeline and a brushing pipeline, a drain valve is arranged in the water tank, and a drain outlet of the drain valve is communicated with the injection pipeline, and the efficient flushing pedestal pan is characterized by further comprising a hydraulic driving mechanism which is connected to the drain valve and can drive the drain valve to drain water; the hydraulic driving mechanism is provided with a hydraulic cavity, a water inlet and a water outlet, the water inlet and the water outlet can be communicated with the hydraulic cavity, the water inlet is connected with an external pressure water source, and the water outlet is communicated to the scrubbing pipeline inlet so that the external pressure water source can flow into the water inlet. And an external pressure water source flows out from the water outlet and is sprayed out from the scrubbing pipeline to flush the peripheral wall of the toilet bowl body. The external pressure water source is used for supplying water to the scrubbing pipeline after the drain valve is opened, the utilization efficiency of the water source is extremely high, and meanwhile flushing control is easy and convenient.

Owner:XIAMEN AXENT

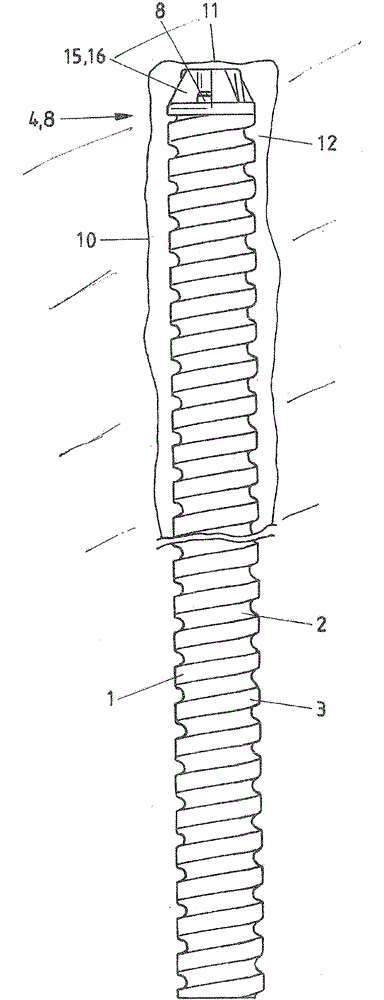

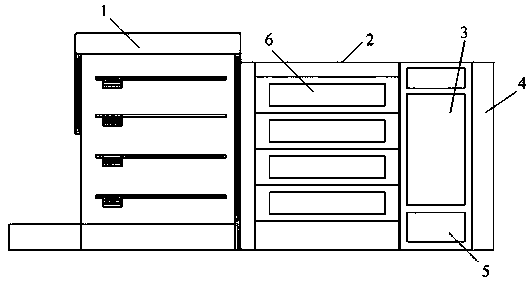

Anchor with separate mixing and discharge heads

Rock bolts (1) exist in various forms, wherein it is particularly advantageous if the discharge end (4) is provided with a mixing head (15), into which the required exit hole (8) is integrated. This exit hole (8) is protected by the shape of the head (16) of the mixing head (15) in such a way that a reliable discharge of the anchoring mixture is always guaranteed even if there are drillings still situated in the borehole. Furthermore, the anchoring cartridge (7) upon the application of pressure is reliably torn open so that the two components pass into the region of the static mixer (9) and are then discharged in the mixed state so that the cavity (12) around the bolt tube (2) is reliably filled.

Owner:MINOVA INT

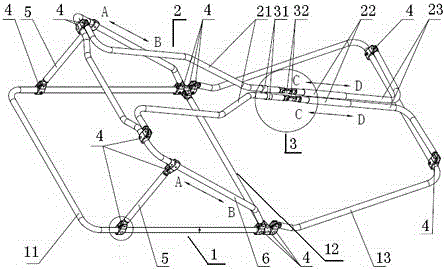

Folding duck canopy structure

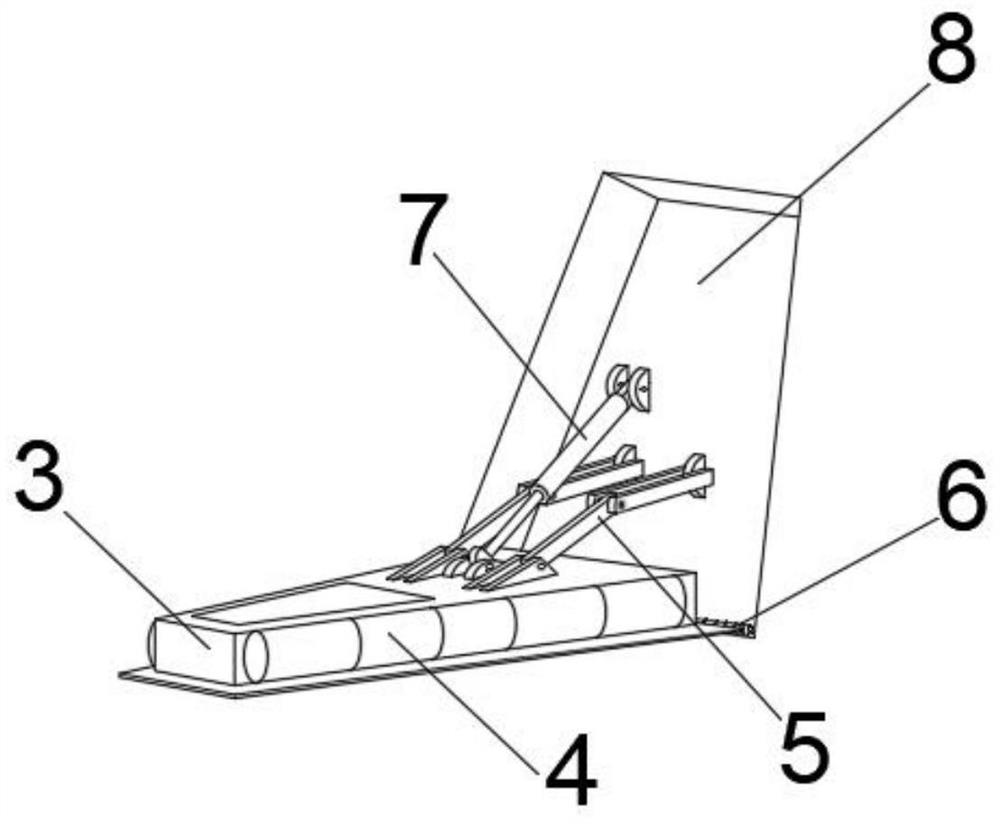

ActiveCN104782612BReasonable structural designSimple preparation processAnimal huntingStructural engineeringEngineering

The invention discloses a folding duck catching shed structure, and belongs to the technical field of poultry catching tools. The folding duck catching shed structure comprises a base assembly, rock cover assemblies and a hinge assembly. The base assembly is formed by a head side base bend, a base middle supporting pipe and a foot side base bend. The base middle supporting pipe and the foot side base bend are fixedly hinged to the two ends of the head side base bend and the extending parts of the two ends of the head side base bend through the hinge assembly. The rock cover assemblies are symmetrically arranged on the base assembly, and are two structures opened and closed oppositely, and the rock cover assemblies are mainly composed of rock cover upper pipes, pull rod locating casing pipes, rock cover lower pipes, headrest pipes and rock cover hinge components. The rock cover upper pipes and the rock cover lower pipes are fixedly hinged to the headrest pipes and the foot side base bend respectively. The two ends of the headrest pipes are fixedly hinged to the head side base bend. The folding duck catching shed structure has the advantages of being reasonable in structural design and simple in manufacturing process, and saving time and labor in mounting and dismounting, and is small in size, light, convenient to carry, economical and practical.

Owner:泰州润元户外用品股份有限公司

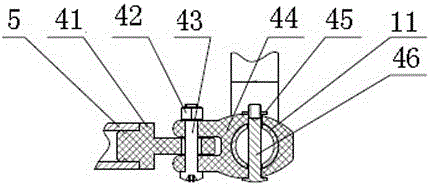

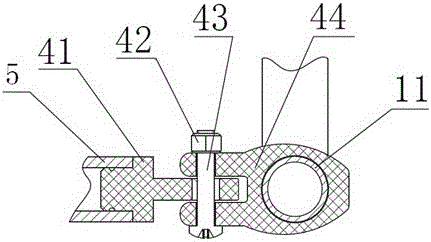

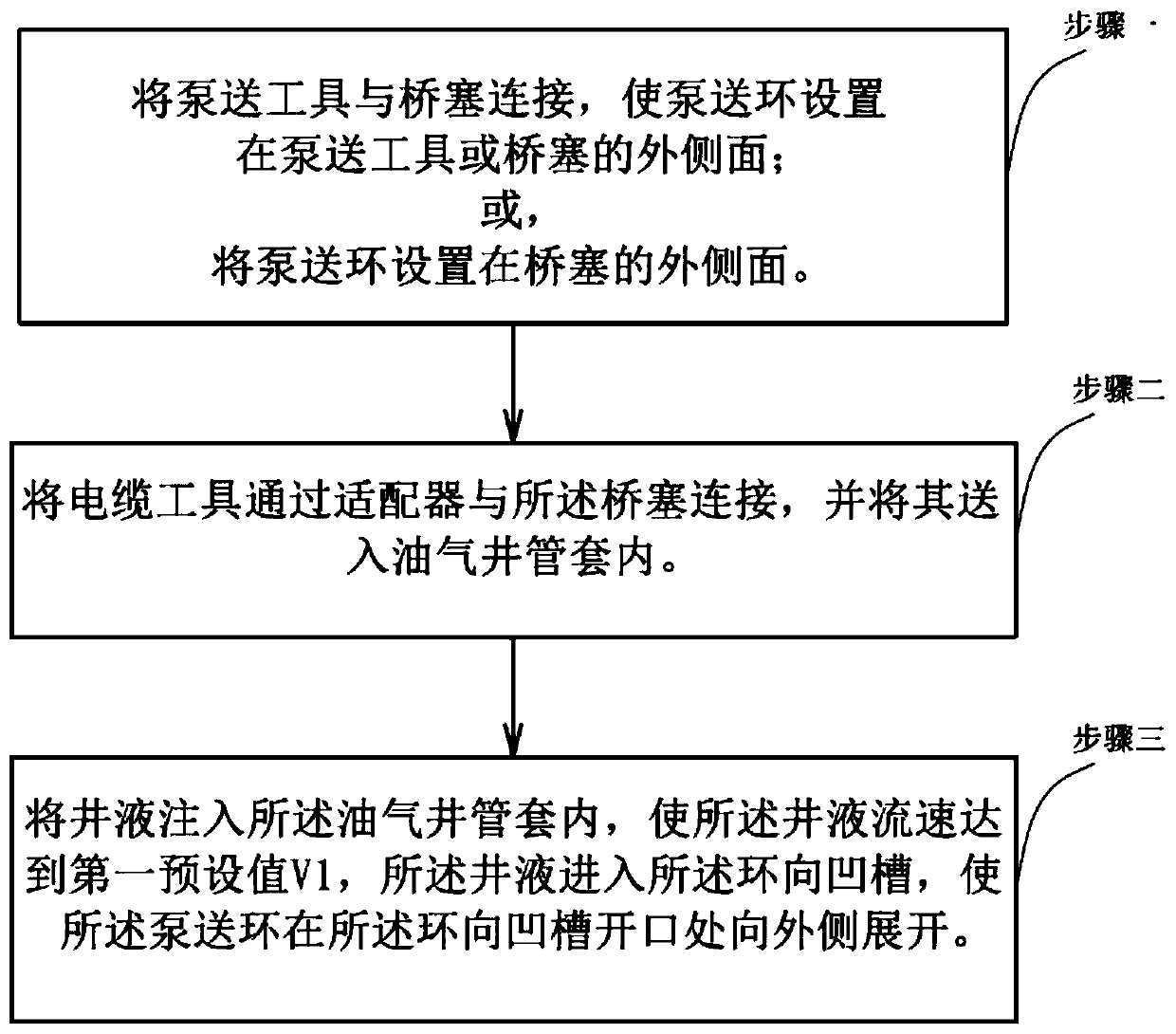

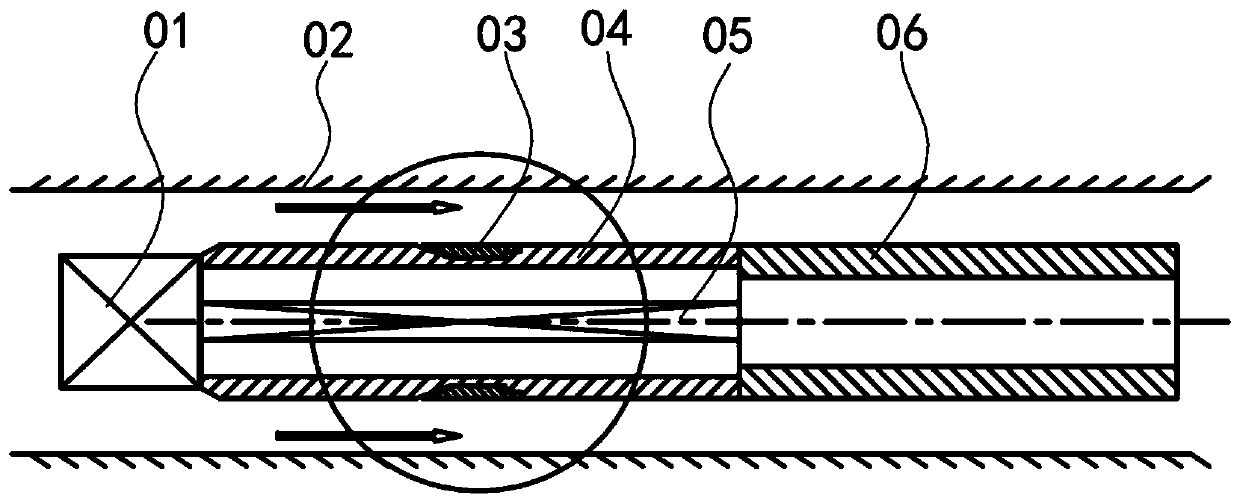

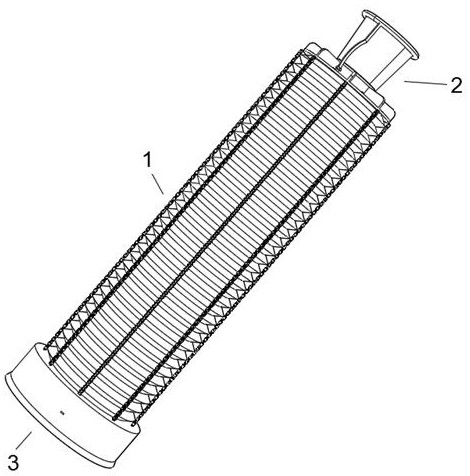

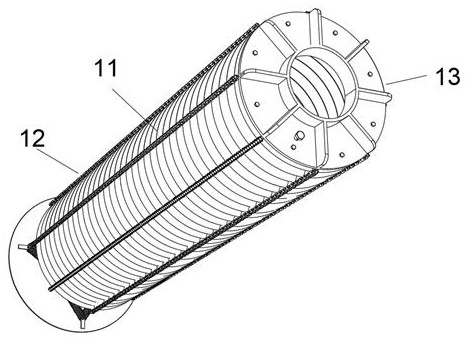

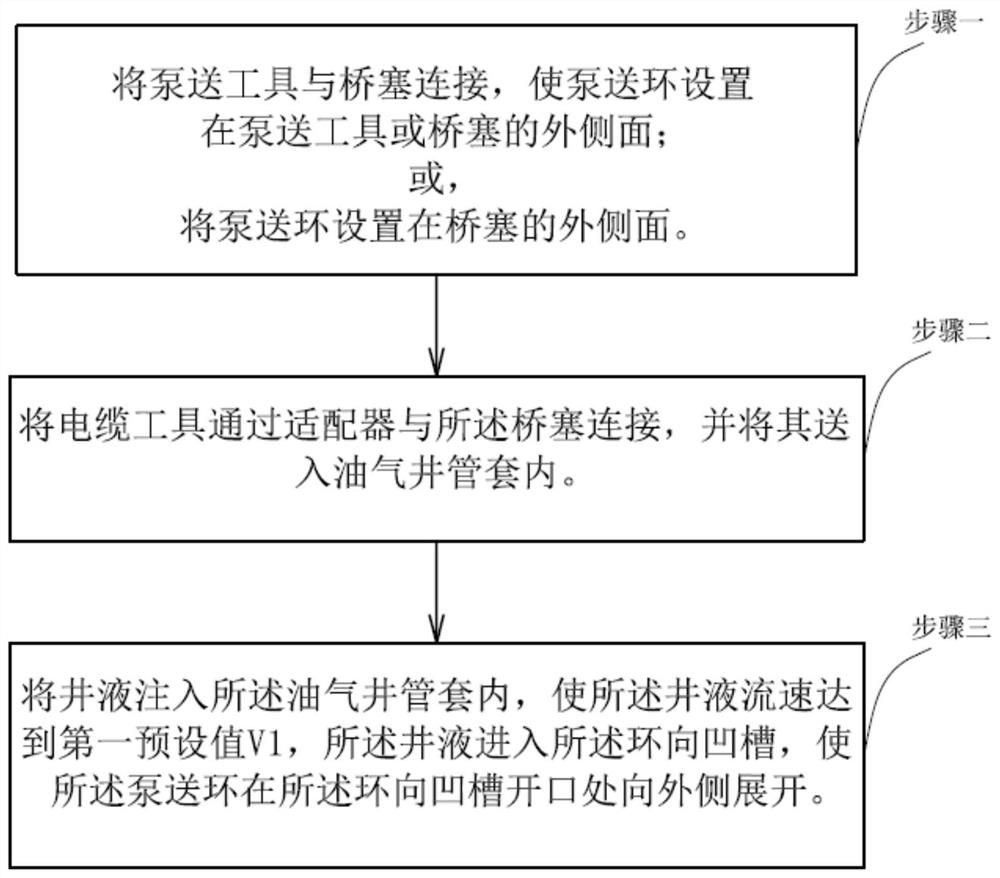

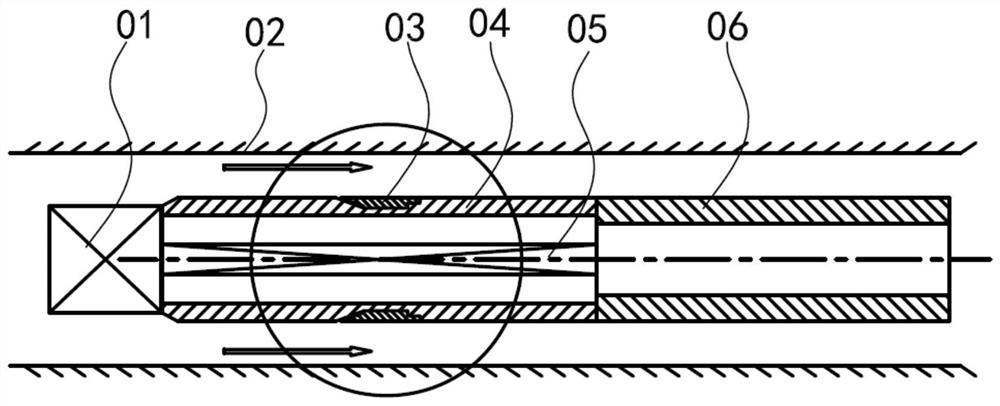

Downhole pumping method

ActiveCN110107241AIncrease the pushing areaReduce flow rateFluid removalInternal pressureEngineering

The invention discloses a downhole pumping method. A pumping ring is arranged on the outer side face of a pumping tool or a bridge plug, in the pumping process, the flow speed of drilling fluid reaches a first preset value V1, the drilling fluid enters a circumferential groove, at the edge of the circumferential groove, the internal pressure of the circumferential groove is greater than the external pressure of the circumferential groove, and thus the pumping ring is expanded towards the outer side at an opening of the circumferential groove; and at the moment, the pumping ring is expanded towards the outer side, thus the outer diameter of a setting tool is increased temporarily, that is, the pushing area of the bridge plug is increased, and accordingly, the setting tool and the bridge plug connected with the setting tool are more effectively pushed by the drilling fluid. The pumping process is accelerated, and the time is saved.

Owner:CHENGDU INNOX TECH CO LTD

A back-purging device for measuring gas pipelines

ActiveCN111520611BReliable isolation and sealingMake sure to openOperating means/releasing devices for valvesPipeline systemsSolenoid valveEngineering

Owner:XIAN JINGZHAO POWER TECH

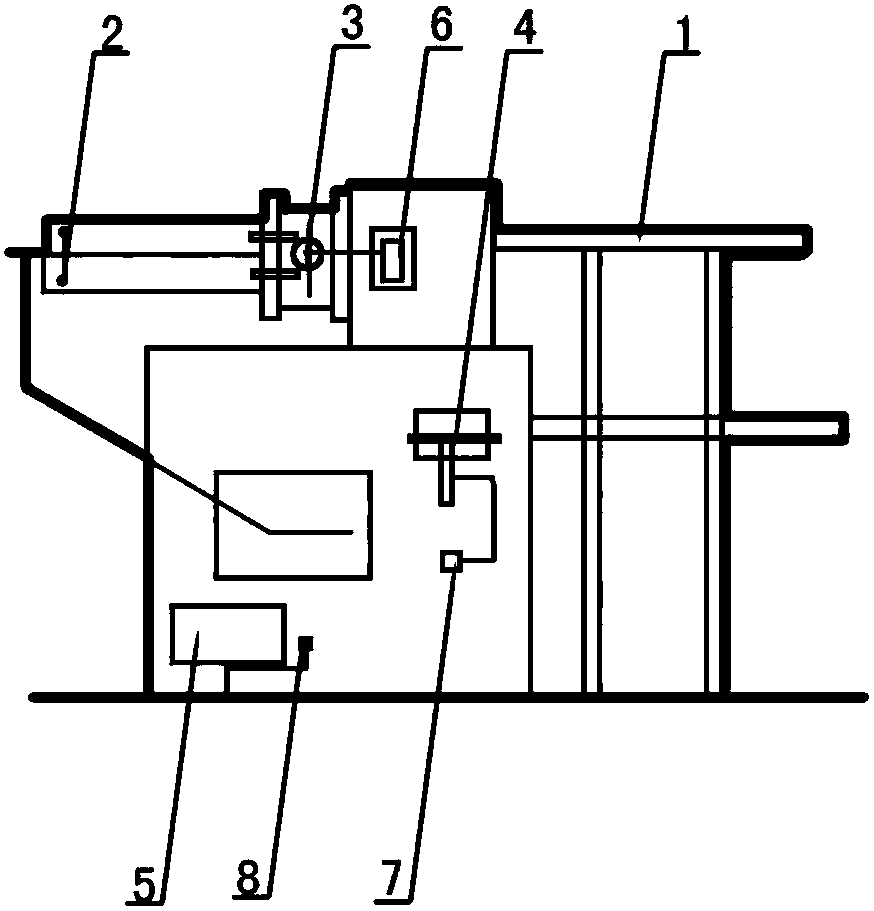

Pore diameter correction safety protection device of straightening and cutting machine

The invention discloses a pore diameter correction safety protection device of a straightening and cutting machine. The device comprises a machine body (1), an infrared measuring module (2), a reference adjusting module (3), an information induction module (4) and a management module (5) are arranged on the machine body (1); during running, the infrared measuring module (2) is arranged on the straightening pore diameter, and measures the material related length, the reference adjusting module (3) adjusts the length of the pore diameter, the information induction module (4) is arranged on a starting component, the management module (5) processes comprehensive information, a numerical value display module (6) is arranged on the reference adjusting module (3), and displays the material measured length and the pore diameter needed length in real time, a protection hinting module (7) is arranged on the information induction module (4), and when inducing machine body run and a protection cover is not opened, the protection hinting module (7) hints opening; a prompt module (8) is arranged on the management module (5); according to the material length, the pore diameter reasonable length is corrected, it is ensured that during running, the protection cover is opened, and work is smooth.

Owner:XINCHANG KANGHONG MACHINERY TECH

Electric vacuum pumps for motor vehicles

ActiveCN102865229BMake sure to openEffective "secondary" airflowRotary piston pumpsRotary piston liquid enginesMobile vehiclePlastic materials

The electrically driven vacuum pump (1) is connected with an aggregate at an inlet port (2) through a connecting line. A negative pressure is generated in the aggregate, where a check valve is arranged between the vacuum pump and the aggregate. A control and monitoring unit is arranged, where an opening is formed downstream of the check valve. The opening is enclosed by a refractory material (6) which melts at a predetermined melting temperature. The refractory material is made of a plastic material, particularly synthetic resin.

Owner:FORD GLOBAL TECH LLC

Repair process and preparation process of tubular perc solar cells

ActiveCN107331730BEL yield improvementIncrease power generationFinal product manufactureSemiconductor/solid-state device manufacturingNitrogenRoom temperature

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +1

Dust cover for oxygen lance

The invention belongs to the technical field of metallurgical industry accessories, and particularly relates to a dust cover for an oxygen lance. The dust cover comprises a protection mechanism, a power mechanism and a bottom mechanism, the protection mechanism sleeves the power mechanism, the bottom end of the power mechanism is slidably inserted into the bottom mechanism, and the two ends of the protection mechanism are fixedly connected with the power mechanism and the bottom mechanism respectively. After the protection mechanism is installed on the oxygen lance, the protection mechanism comprises a gooseneck type dustproof pipe, a positioning chain and a top moving disc, when a sliding rod body and a top sliding rod move upwards, the top moving disc drives the gooseneck type dustproof pipe to be unfolded, when the gooseneck type dustproof pipe is unfolded, the chain is unfolded along with the gooseneck type dustproof pipe, and therefore the situation that the gooseneck type dustproof pipe is unfolded unevenly is avoided, and the opening of the gooseneck type dustproof pipe is ensured, and in the working process of the oxygen lance, the gooseneck type dustproof pipe can filter 95% of waste gas, the waste gas is prevented from being directly discharged into air in the using process of the oxygen lance, and safety accidents caused by the fact that steel slag is splashed out of a furnace in the working process of the oxygen lance can be avoided.

Owner:金铎

A kind of downhole pumping method

ActiveCN110107241BIncrease the pushing areaReduce flow rateFluid removalEngineeringMechanical engineering

Owner:CHENGDU INNOX TECH CO LTD

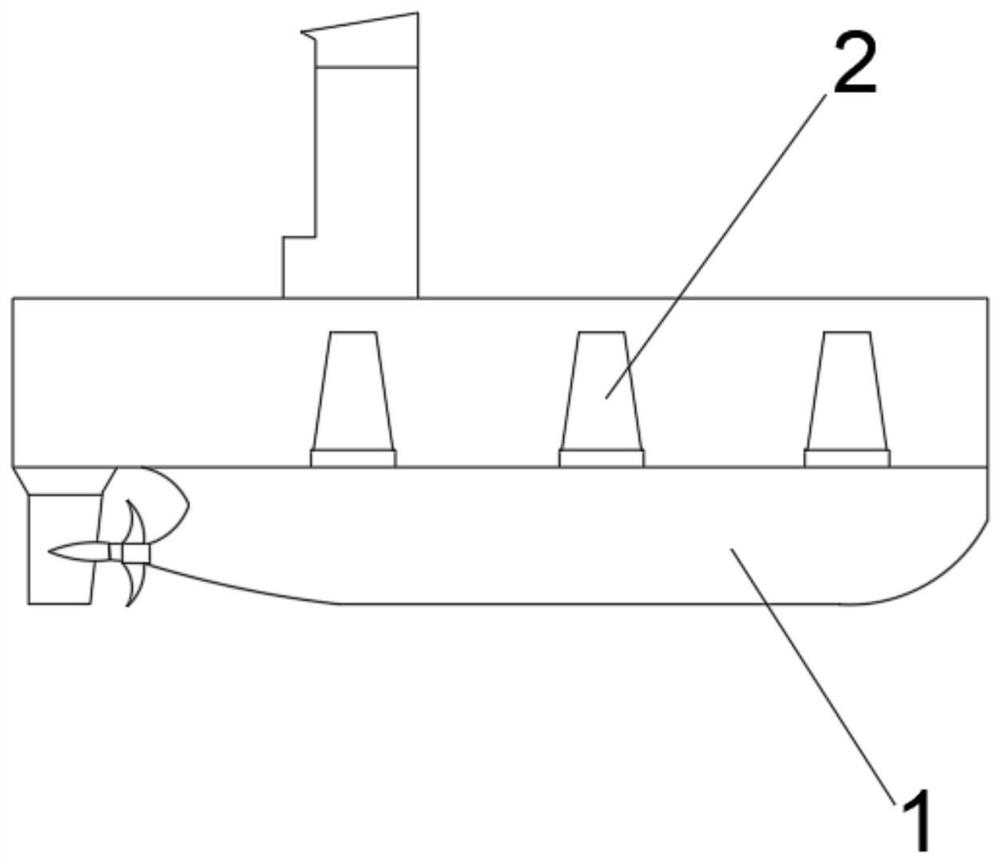

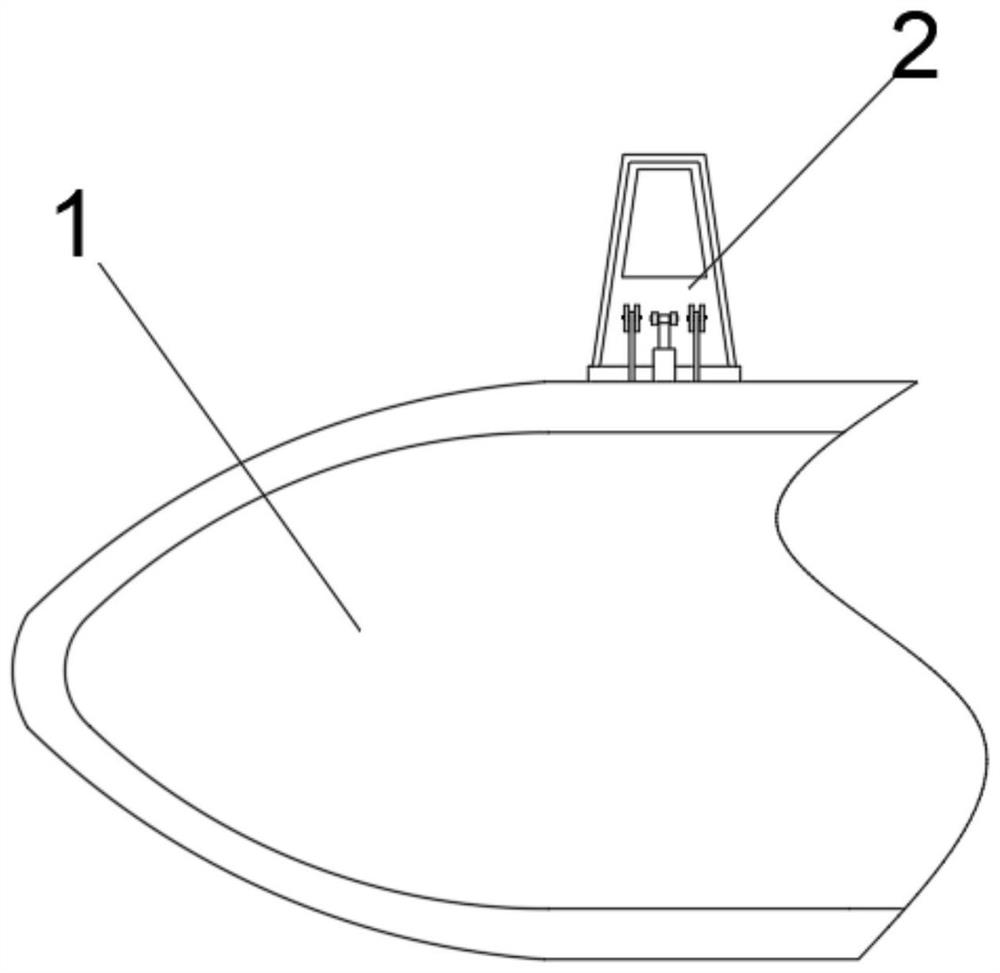

Water transportation channel safety management device

ActiveCN113306672AMake sure to openMake sure it's closedClimate change adaptationVessel movement reduction by foilsWind waveStructural engineering

The invention discloses a water transportation channel safety management device which comprises a ship body, a plurality of grooves are formed in the two side faces of the ship body, protection devices are movably arranged in the grooves and comprise rotating plates connected with the grooves through rotating shafts, two ends of a driving device and two ends of a rotating mechanism are fixedly connected with the rotating plates and the inner walls of the grooves correspondingly, an expansion mechanism is arranged on each rotating plate, and a deformation mechanism which is arranged in each rotating plate and controls the corresponding expansion mechanism to expand and contract. According to the device, extra extension and extra buoyancy are provided for the ship body through the expansion mechanisms, and the width and the overall buoyancy of the ship body are increased. Therefore, it is guaranteed that the ship is not prone to inclining leftwards and rightwards under stormy waves, the safety of the ship body and sailors is guaranteed, the integrity of goods during transportation is improved, and the balance degree of the ship during running is improved.

Owner:NANJING HYDRAULIC RES INST

A reciprocating plywood production device

ActiveCN112077955BAvoid burnsReduced risk of burnsPlywood pressesVeneer pressesStructural engineeringMechanical engineering

The invention discloses a reciprocating plywood production device, which belongs to the field of plywood processing. There is a lower hot-pressing plate, and an upper hot-pressing plate is arranged above the lower hot-pressing plate, and the upper hot-pressing plate reciprocates and lifts under the action of the hot-pressing driving device, and the end surface of the lower hot-pressing plate is provided with a chute through which both ends are spaced apart. There is a connecting part movable in the groove, and the two ends of the connecting part are oppositely provided with a slab placing frame. The plate is connected with the sliding part, which is arranged on the upper end of the frame and slides reciprocally along the length direction of the chute, and the sliding part is provided with a discharge driving device for pushing the loading plate to turn down. The purpose of the present invention is to provide a reciprocating plywood production device, which can conveniently take out the rough board from the hot pressing equipment.

Owner:湖南闽新新材料股份有限公司

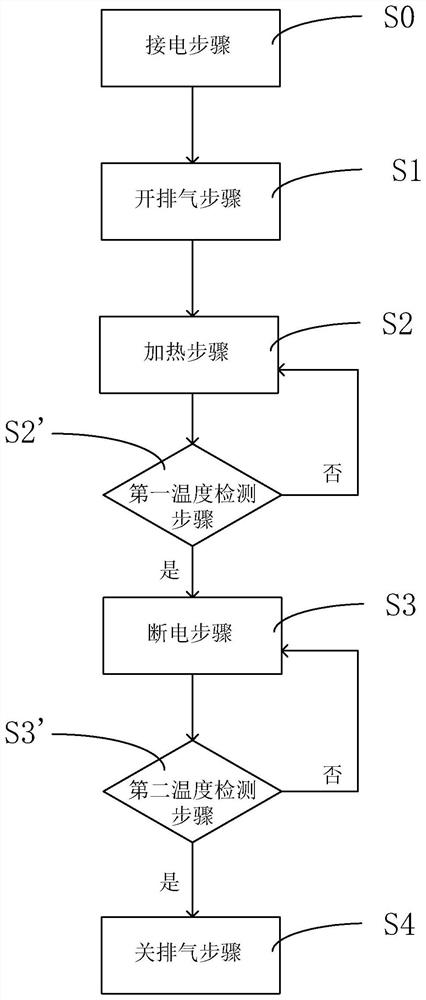

Electric heating cup water boiling exhaust control method

PendingCN112336183ASolve usabilityFix security issuesWater-boiling vesselsThermodynamicsProcess engineering

The invention relates to the technical field of water boiling containers, and provides an electric heating water cup water boiling exhaust control method which is applied to an electric heating watercup with a heating assembly, an exhaust assembly and a control assembly, and the method comprises the following steps: starting the exhaust assembly, starting the heating assembly, closing the heatingassembly and closing the exhaust assembly. Compared with an electric heating water cup in the prior art, the method has the advantages of being high in automation degree and good in water boiling safety performance.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

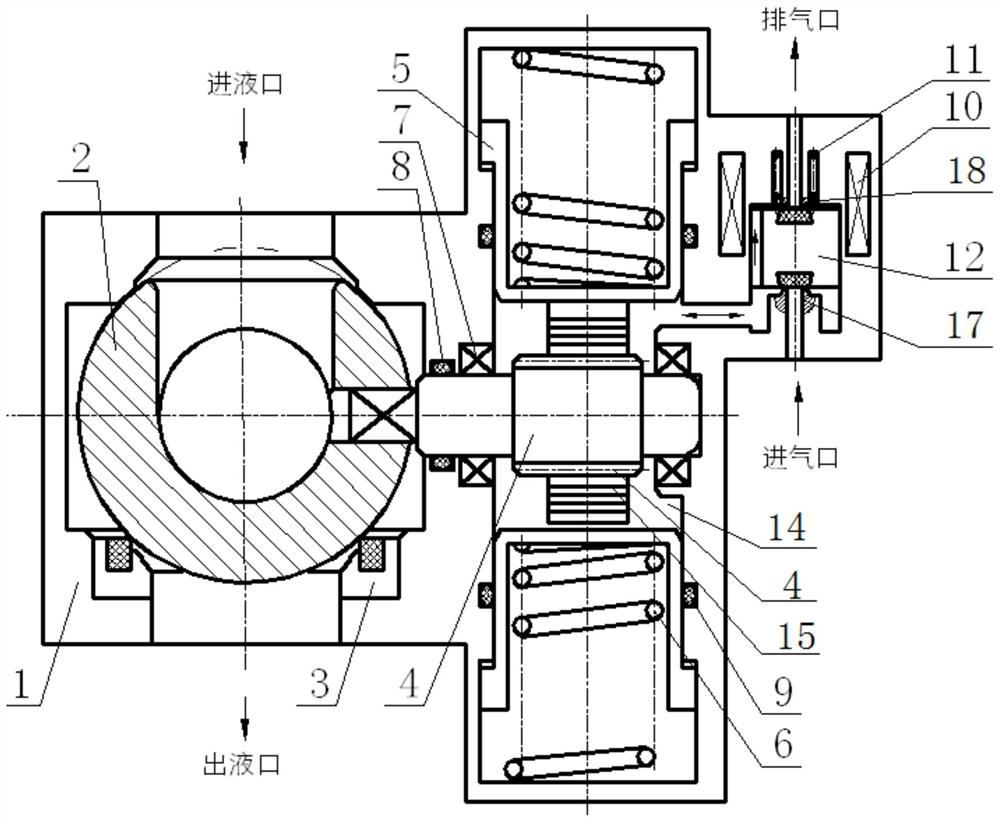

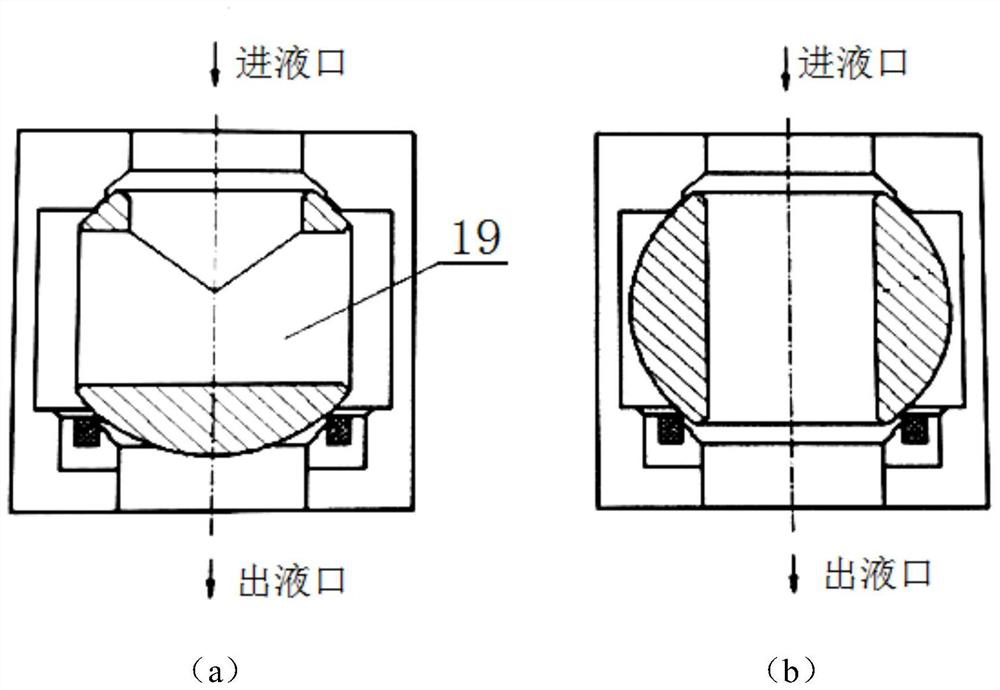

Large-caliber electromagnetic pilot pneumatic control piston rack transmission ball valve

InactiveCN112303276ALarge diameterStrong circulationPlug valvesOperating means/releasing devices for valvesEngineeringControl valves

In order to solve the technical problem that the existing electromagnetic control valve can hardly meet the requirements of high-flow quick discharge and high-reliability action, the invention provides a large-caliber electromagnetic pilot pneumatic control piston rack transmission ball valve which comprises a pneumatic piston rack and gear shaft transmission mechanism, an electromagnetic auxiliary valve and a main valve. The electromagnetic auxiliary valve is of a two-position three-way valve structure and used for achieving inflation pressure building and exhaust pressure relief in a pistonair cavity of the pneumatic piston rack and gear shaft transmission mechanism, and therefore the on-off control over the large-diameter main valve by the small-size electromagnetic auxiliary valve isachieved through the pneumatic piston rack and gear shaft transmission mechanism, and the purpose of electromagnetic pilot control is achieved.

Owner:XIAN AEROSPACE PROPULSION INST

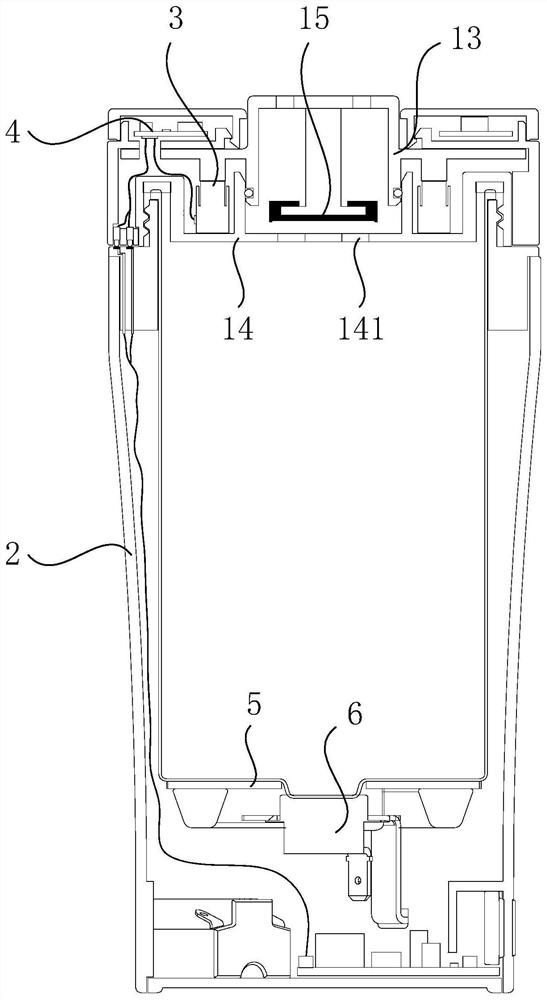

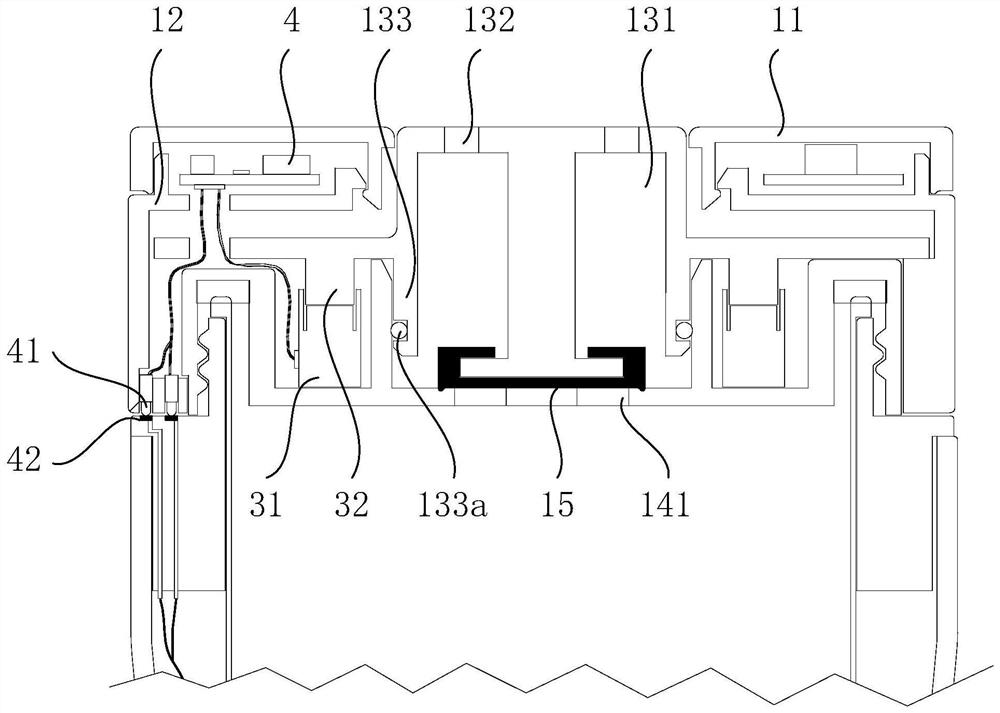

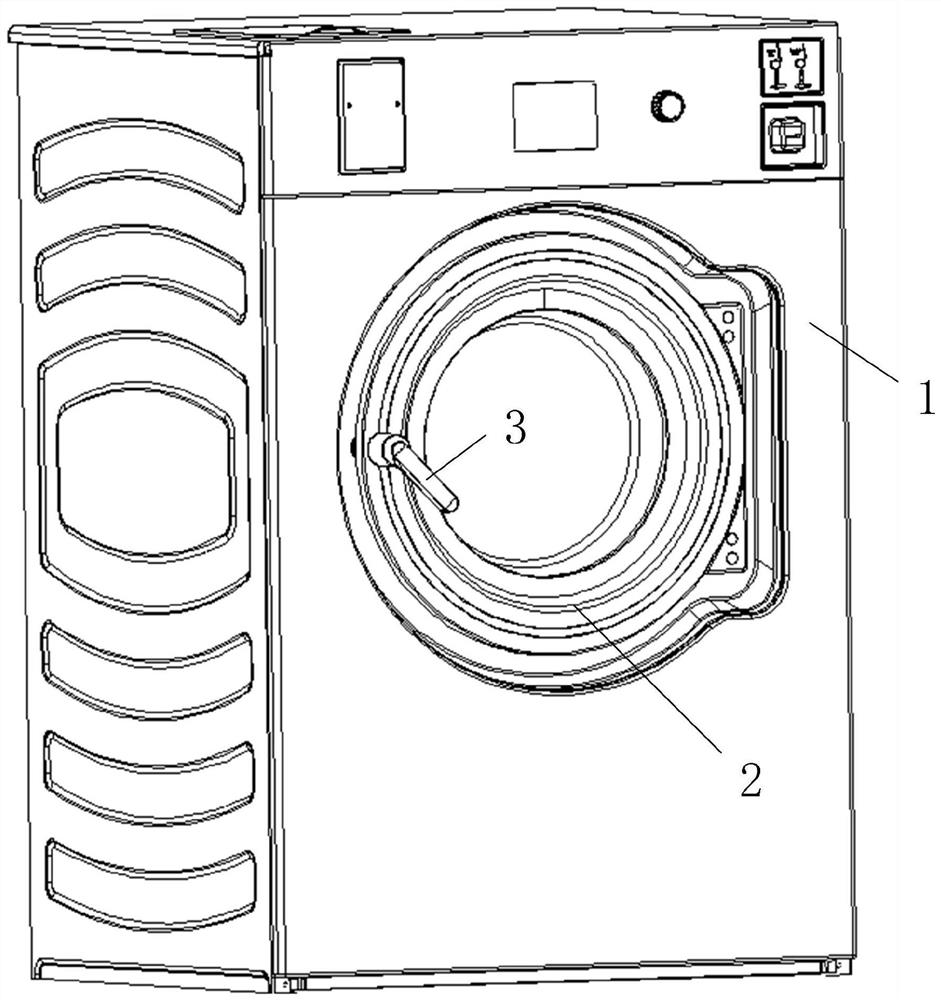

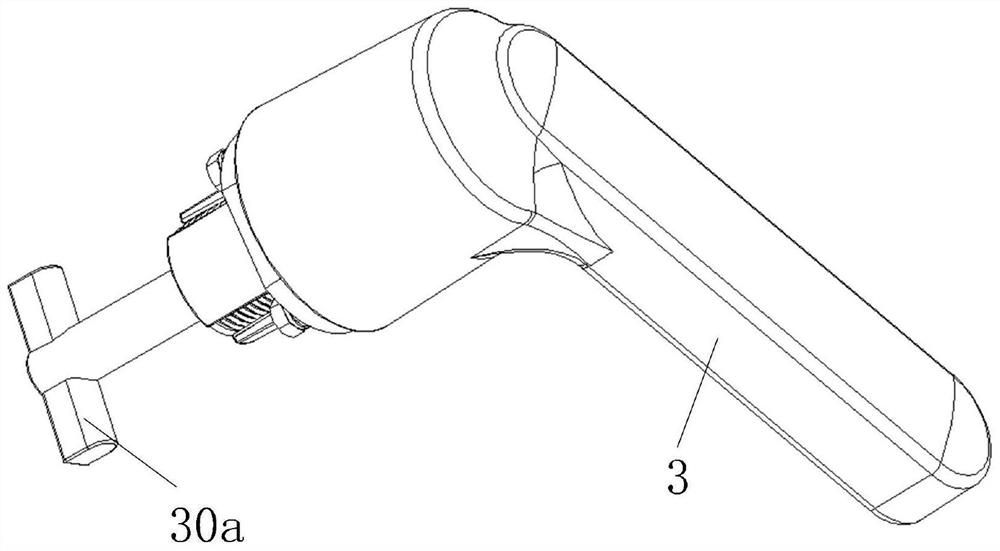

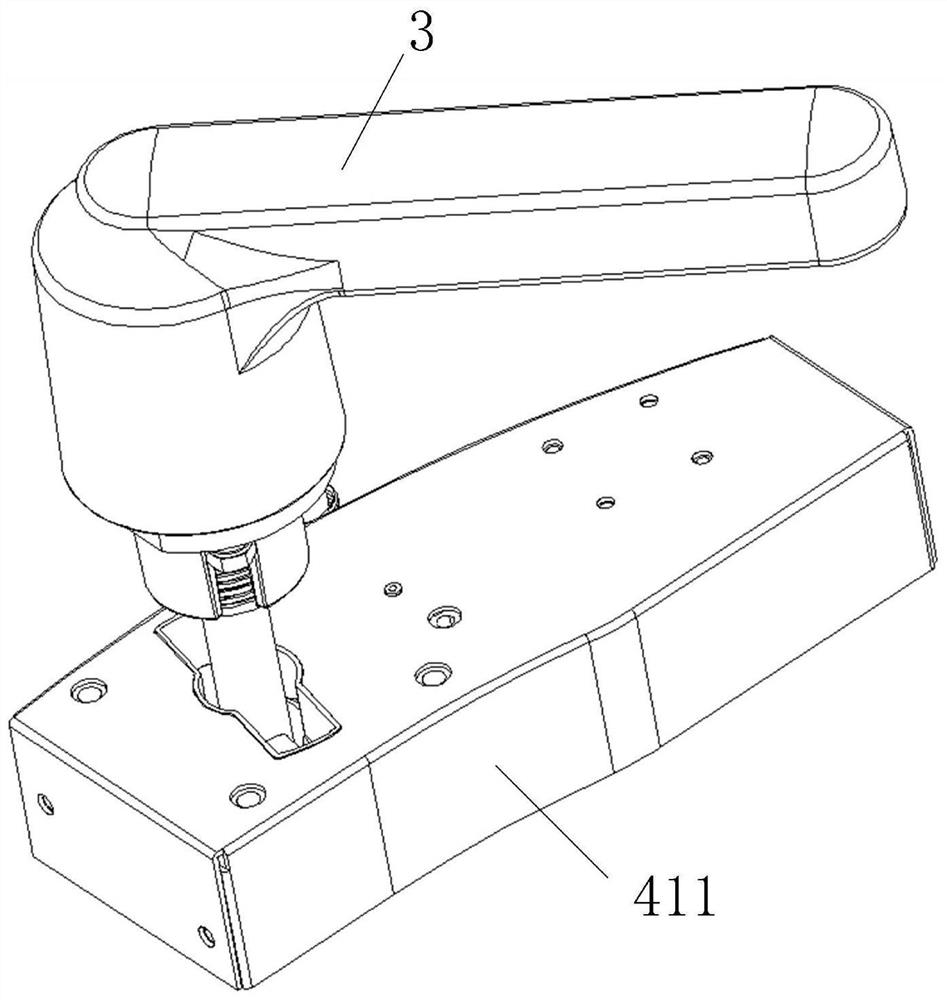

Clothes treatment equipment

PendingCN113338008AEasy to lockEasy to removeNon-mechanical controlsOther washing machinesMechanical engineeringMedicine

The invention belongs to the technical field of clothes treatment, and provides clothes treatment equipment. The problem that a user cannot open a door body when existing clothes treatment equipment is used for treating clothes and an emergency occurs is solved. The clothes treatment equipment comprises a door lock device and an emergency device arranged on the door lock device. The emergency device comprises an operation part, a first trigger part and a first switch, under the condition that a limiting assembly limits a rotating part in a second position, the operating part can move under the action of external force to enable the first trigger part to open / close the first switch, so that a controller sends an unlocking instruction to the limiting assembly, the limiting assembly relieves limiting of the rotating part, and a holding part is allowed to drive the rotating part to rotate from the second position to the first position. When the door body needs to be opened in an emergency situation, even if a drum-type washing machine is used for treating clothes, a user can open the door body to deal with the emergency situation, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Tubular perc single-sided solar cell and its preparation method and special equipment

ActiveCN107256894BImprove passivation effectImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingElectrical batterySilicon oxide

The invention discloses a tubular PERC single-sided solar cell, which comprises a back silver main grid, an all-aluminum back electric field, a back composite film, a P-type silicon, an N-type emitter, a front passivation film and a front silver electrode; The film includes one or more of aluminum oxide film, silicon dioxide film, silicon oxynitride film and silicon nitride film, and is deposited on the back of the silicon wafer by using tubular PECVD equipment. There are four gas pipelines for silane, ammonia, trimethylaluminum, and laughing gas. The device for loading and unloading silicon wafers of the tubular PECVD equipment is a graphite boat, and the depth of the stuck groove of the graphite boat is 0.5-1mm. The invention also discloses a preparation method and special equipment for a tubular PERC single-sided solar cell. By adopting the invention, the photoelectric conversion efficiency is high, the appearance yield rate and EL yield rate are high, and the problems of scratches and winding plating are solved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

A plywood pressing equipment

ActiveCN112123475BAvoid burnsReduced risk of burnsPlywood pressesVeneer pressesEngineeringMechanical engineering

The invention discloses a plywood pressing device, which belongs to the field of plywood processing. Under the action of reciprocating lifting, the upper part of the lower heat press plate is provided with a horizontally sliding slab placement frame, and the slab placement frame includes beams arranged horizontally at intervals and a connecting plate arranged between the two beams. The upper surface of the pressure plate is provided with a chute matching the crossbeam; the side end of the crossbeam is hinged with a loading plate that can be reset to a horizontal state, and the loading plates on both sides are arranged opposite to each other; the upper end of the base is provided with a frame, and the The frame is provided with an unloading driving device that pushes the loading plate to turn down. The purpose of the present invention is to provide a plywood pressing equipment, which can conveniently take out the raw board from the hot pressing equipment.

Owner:湖南闽新新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com