High-sealing low-friction one-way bearing

A one-way bearing, low-friction technology, applied in the direction of bearing components, shafts and bearings, rolling resistance optimization, etc., can solve the problem of not being able to have both sealing performance and speed, and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

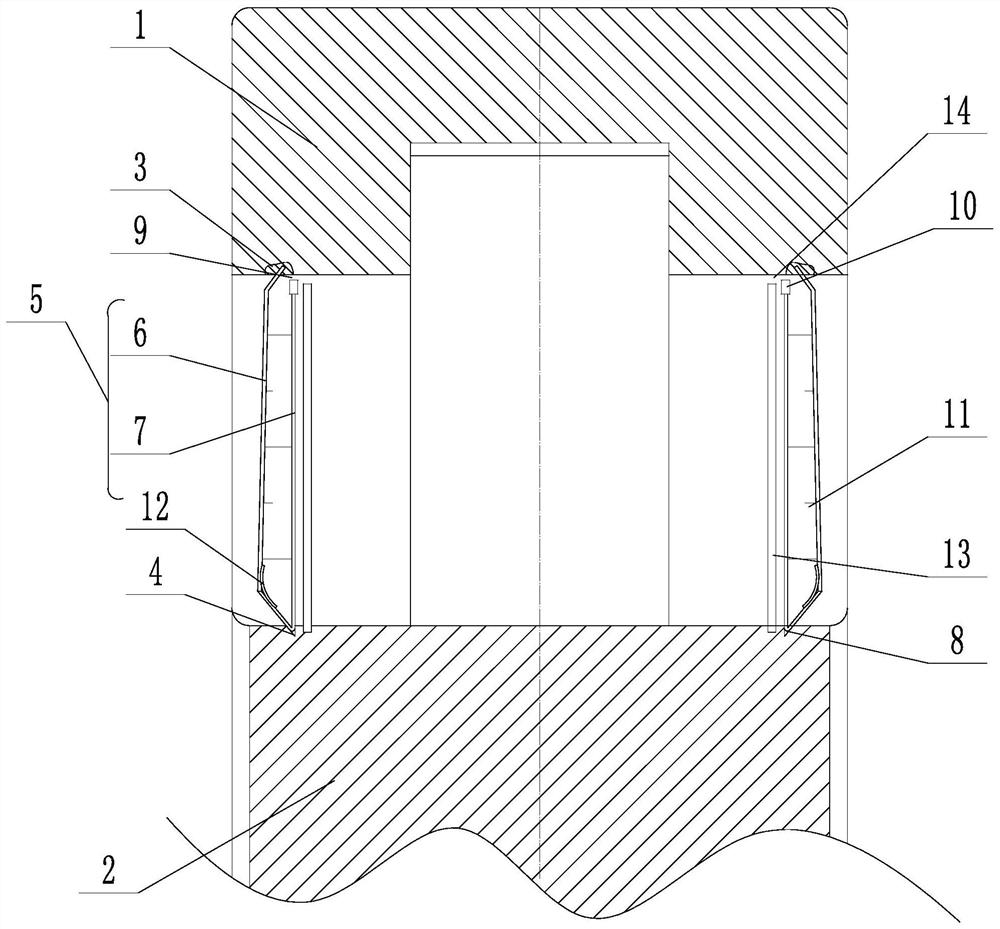

[0029] Example 1:

[0030] A unidirectional bearing of high-density, low friction, such as figure 1 , 2 As shown, the one-way bearing includes a bearing outer casing 1 and a bearing inner sleeve 2, and the bearing outer casing 1 is provided with a resigning groove 3, and the bearing inside 2 corresponds to the position of the restricted groove 3, corresponding to the sealing groove 4. The bearing outer casing 1 and the bearing inner sleeve 2 are provided with a seal ring 5, and the material of the seal is nylon. Since the sealing ring 5 is annular, in the process of its motion, a certain circumferential change is generated, and the material of nylon can support this deformation so that it always adapts to the bearing. The sealing ring 5 includes a restricted sheet 6 and a bending sheet 7, a limiting sheet 6, and a bending sheet 7 integrally formed. This structure can reduce the process complexity of the seal 5 and improve productivity. The limit sheet 6 is elastically coupled to ...

Example Embodiment

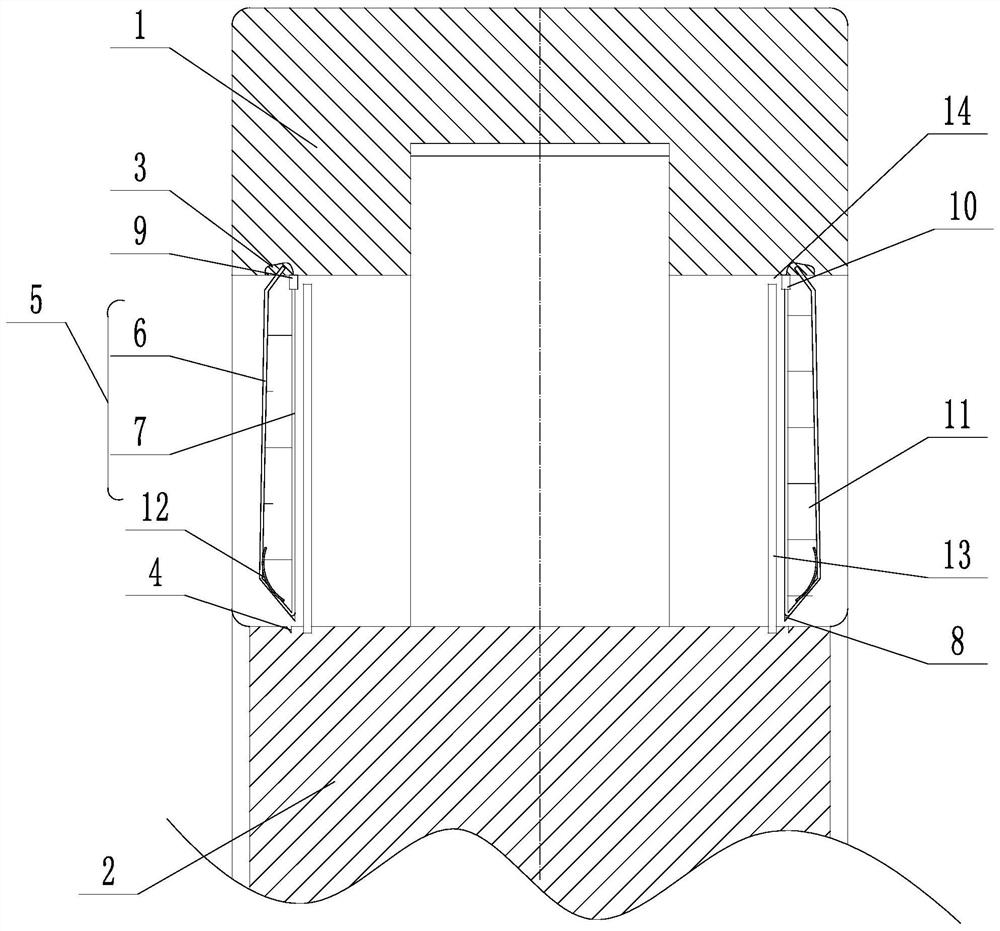

[0034] Example 2:

[0035] The present embodiment also has the following characteristics on the basis of Example 1:

[0036] Such as figure 2 As shown, the bearing inner sleeve 2 is provided with an auxiliary sealing sheet 13 in the inner side of the sealing groove 4, and the auxiliary sealing sheet 13 is fixed to the bearing inner sleeve 2, and the other end is provided with an avoidance gap 14 between the other end and the bearing outer casing 1. This structure can increase a certain sealing property in the case of abuting the fold 8 out of the sealing groove 4 in the bearing motion state.

Example Embodiment

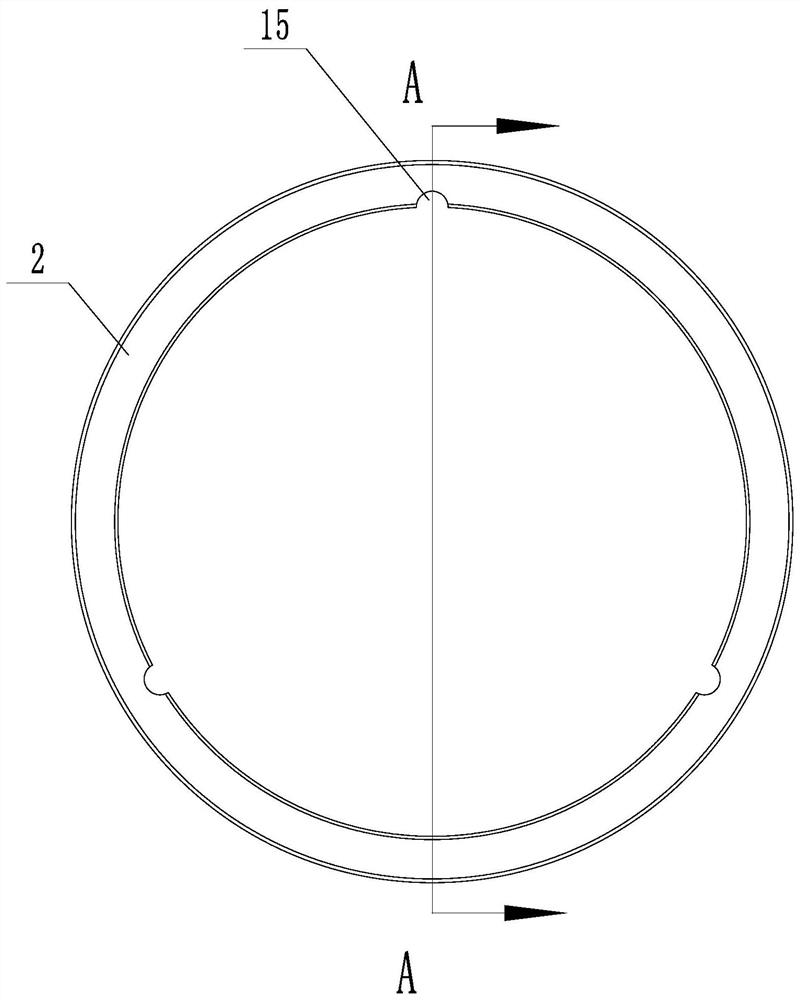

[0037] Example 3:

[0038] The present embodiment also has the following characteristics on the basis of Example 1:

[0039] Such as image 3 , 4 As shown, a positioning key groove 15 is provided on the bearing inner sleeve 2, and the positioning keyway 15 is semi-circular, and the depth of the positioning keyway 15 is half the thickness of the bearing inside of the bearing. The thickness of the inner ring is more uniform, and it is possible to change the stress distribution of the bearing inner ring to prevent the inner ring from deforming due to stress, extending the bond service life; Second, the inner diameter of the inner ring has continuity, and can effectively prevent the grinding wheel during processing Radial jump, improve the temperature of the inner diameter roundness.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap