Universal transmission shaft for bearing

A universal transmission and transmission shaft technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of complex assembly of transmission shafts and connecting sleeves, difficult cost control, and large friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

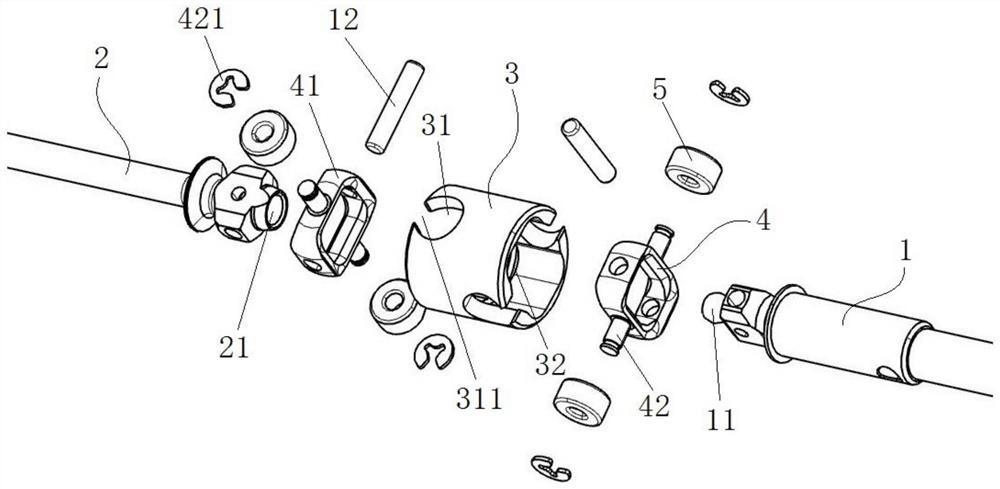

[0031] like figure 1 As shown, a bearing cardan shaft is provided in this embodiment, which mainly includes a first transmission shaft 1, a second transmission shaft 2 and a connecting sleeve 3, and the end of the first transmission shaft 1 connects from the connecting sleeve One end of the cylinder 3 is protruded and set, the end of the second transmission shaft 2 is protruded from the other end of the connecting sleeve 3, and the first transmission shaft 1 is protruded and set on the connecting sleeve 3 One end inside is in transmission connection with the end of the second transmission shaft 2 protruding into the connection sleeve 3; as one of the preferred solutions, the transmission connection here includes in the first transmission shaft 1 A sphere 11 is provided at the end, and a spherical concave surface 21 for the sphere 11 to embed is provided at the end of the second transmission shaft 2, and the sliding contact between the sphere 11 and the spherical concave surfac...

Embodiment 2

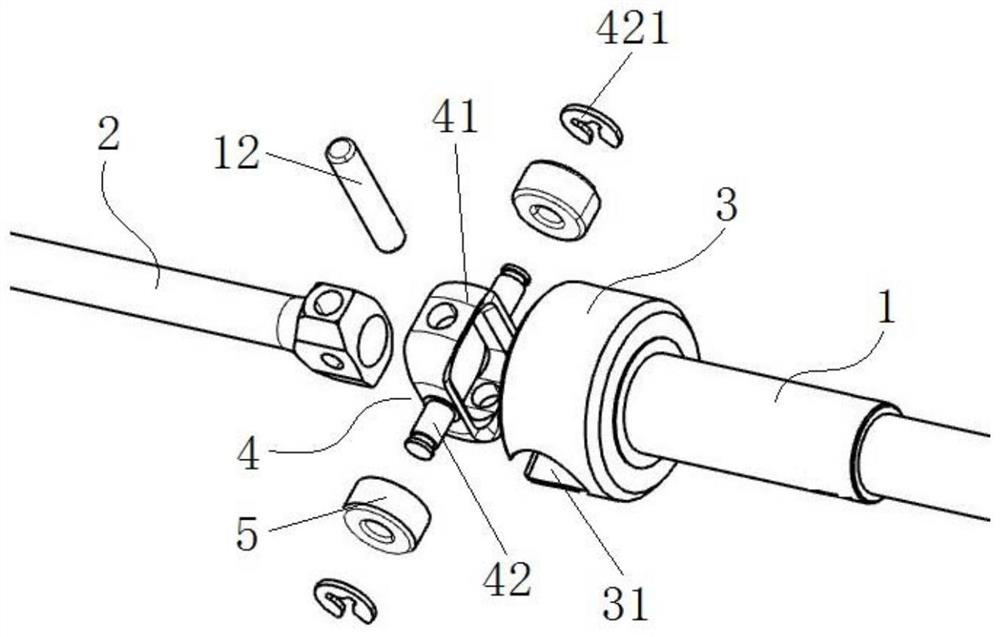

[0043] like figure 2 As shown, the similarities with Embodiment 1 will not be repeated; this embodiment provides another structural form of the bearing cardan shaft, mainly including the first transmission shaft 1, the second transmission shaft 2 and the connecting sleeve 3 .

[0044] The end of the first transmission shaft 1 and one end of the connecting sleeve 3 are in an integrated structure, and the end of the second transmission shaft 2 is protruded from the other end of the connecting sleeve 3. One end of the second transmission shaft 2 protruding into the connecting sleeve 3 is provided with the rotating connecting piece 4, and the connecting column 42 and the bearing are passed between the rotating connecting piece 4 and the connecting sleeve 3. The component 5 and the structural hole 31 form a transmission connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com