Parking system and method with gear shifting grooves of gear shifting drum for driving

A shift drum and parking technology, applied in control/regulation systems, components with teeth, transmission control, etc., can solve the problem of occupying the position of the shift track groove, so as to reduce the radial size and save occupancy Space, direct and effective effect of drive parking system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

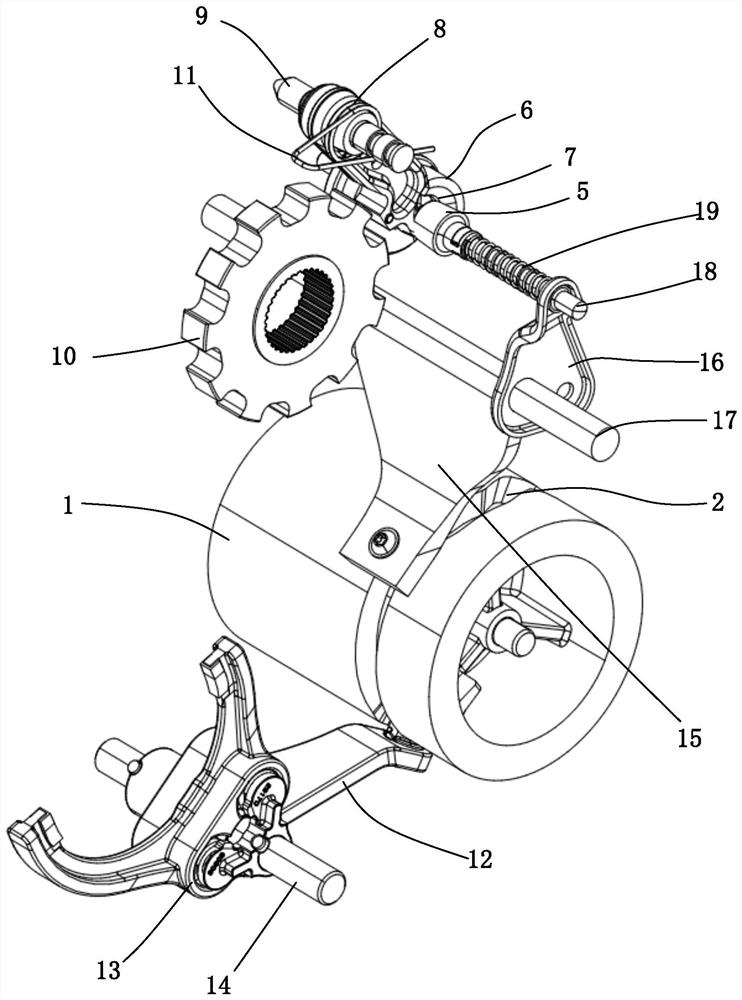

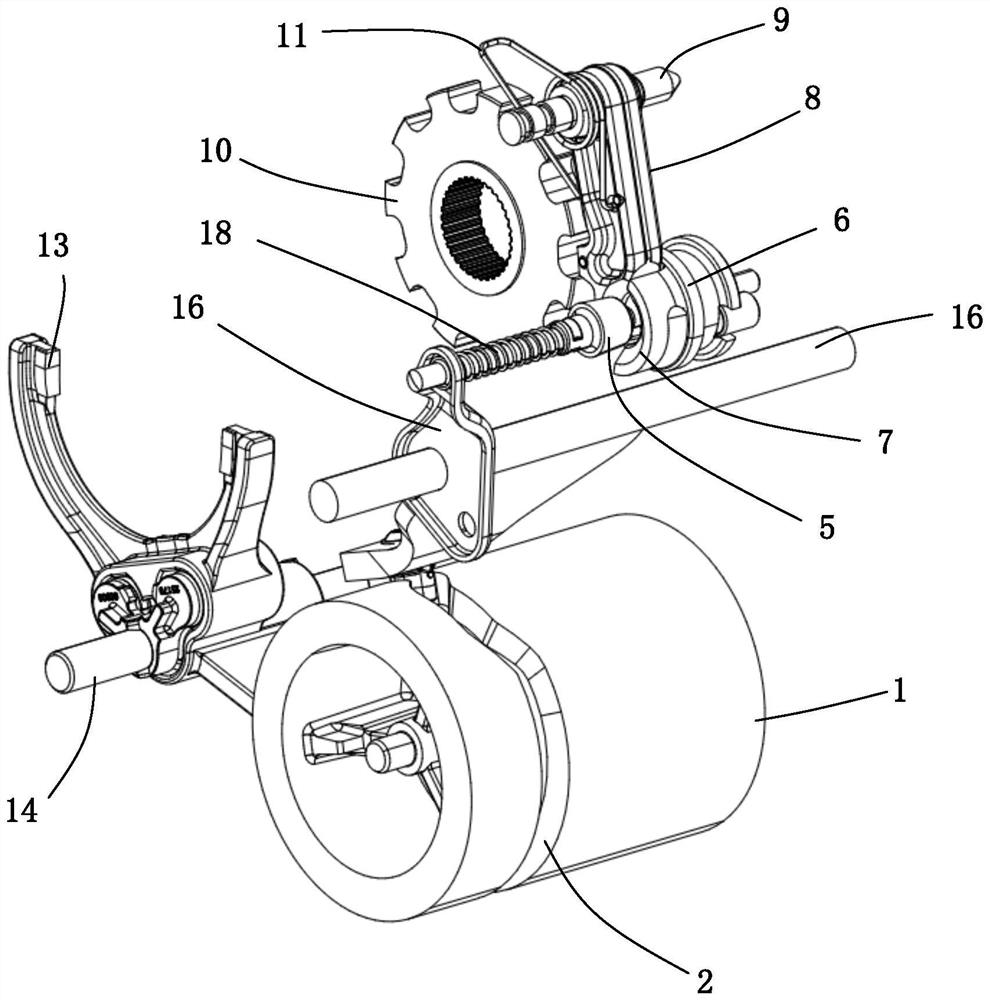

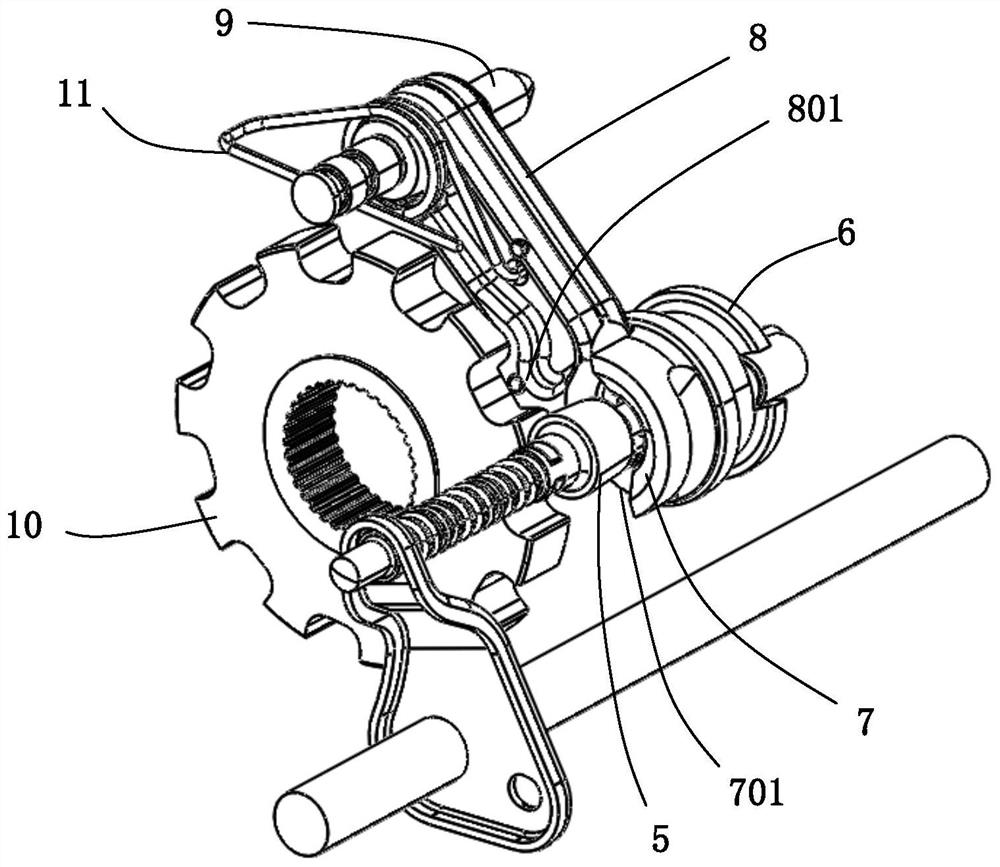

[0044] Such as Figure 1 to Figure 5 As shown, a parking system driven by a shift drum shift groove includes a shift drum 1, and the shift drum 1 includes a shift groove 2, the shift drum 1 is a cylinder, and the shift drum The groove 2 is an annular groove arranged around the circumferential surface of the shift drum 1. The shift groove 2 includes a four / reverse gear groove, and the four / reverse gear groove includes a flat area 201 and is connected to the flat area. The fourth gear area 202 and the reverse gear (R gear) area 203, the fourth gear area 202 and the reverse gear area 203 are respectively arranged in relative offsets along the axial direction of the shift drum 1, and the fourth gear area 202 and the Between the flat areas 201, between the reverse gear area 203 and the flat area 201, oblique area transitions are respectively provided. The shift slot 2 is provided with a shift slider 3 and a parking slider 4. The shift slider 3 is connected to the shift actuator, a...

Embodiment 2

[0059] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the shifting groove includes the second / sixth gear groove, and the second / sixth gear groove includes a flat area 201, and a second gear area 204 connected to the flat groove, The sixth gear area 205, the second gear area 204 and the sixth gear area 205 are arranged with relative offsets along the axial direction of the shift drum 1, between the second gear area 204 and the flat area 201, the sixth gear area There is an oblique zone transition between the zone 205 and the flat zone 201; the second / sixth gear slot is provided with a shift slider 3 and a parking slider 4, while there is no parking slider in the fourth / reverse gear slot 4. The shift slider 3 in the second / sixth gear slot and the shift slider 3 in the fourth / reverse gear slot are at the same circumferential position of the shift drum 1 and move synchronously.

[0060] In this embodiment, the shift drum rotates in rev...

Embodiment 3

[0063] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the shift gate includes a third / fifth gear slot, and the third / fifth gear slot includes a flat area 201, and a third gear area connected to the flat slot, The fifth gear area, the third gear area 206 and the fifth gear area 207 are respectively arranged with relative offsets along the axial direction of the shift drum 1, between the third gear area 206 and the flat area 201, the fifth gear area 207 and the flat area 201 are respectively provided with an oblique area transition; the third / fifth gear slot is provided with a shift slider 3 and a parking slider 4, while there is no parking slider 4 in the fourth / reverse gear slot ; The shift slider 3 in the third / fifth gear slot and the shift slider 3 in the fourth / reverse gear slot are at the same circumferential position of the shift drum 1 and move synchronously.

[0064] In this embodiment, the shift drum rotates in reverse, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com