Drying room for drying tea brick flower and flower drying method of tea brick

A flower drying and tea bricking technology, which is applied in the drying room/container, drying solid materials, dry goods processing, etc., can solve the problem of low qualified rate of Fuzhuan brick tea, the inability to accurately control the temperature and humidity of the flowering drying room, and the temperature and humidity of the drying room. Unable to achieve uniform distribution and other problems, to achieve the effect of reducing dead spots in the area, increasing the probability of blooming, and balancing temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

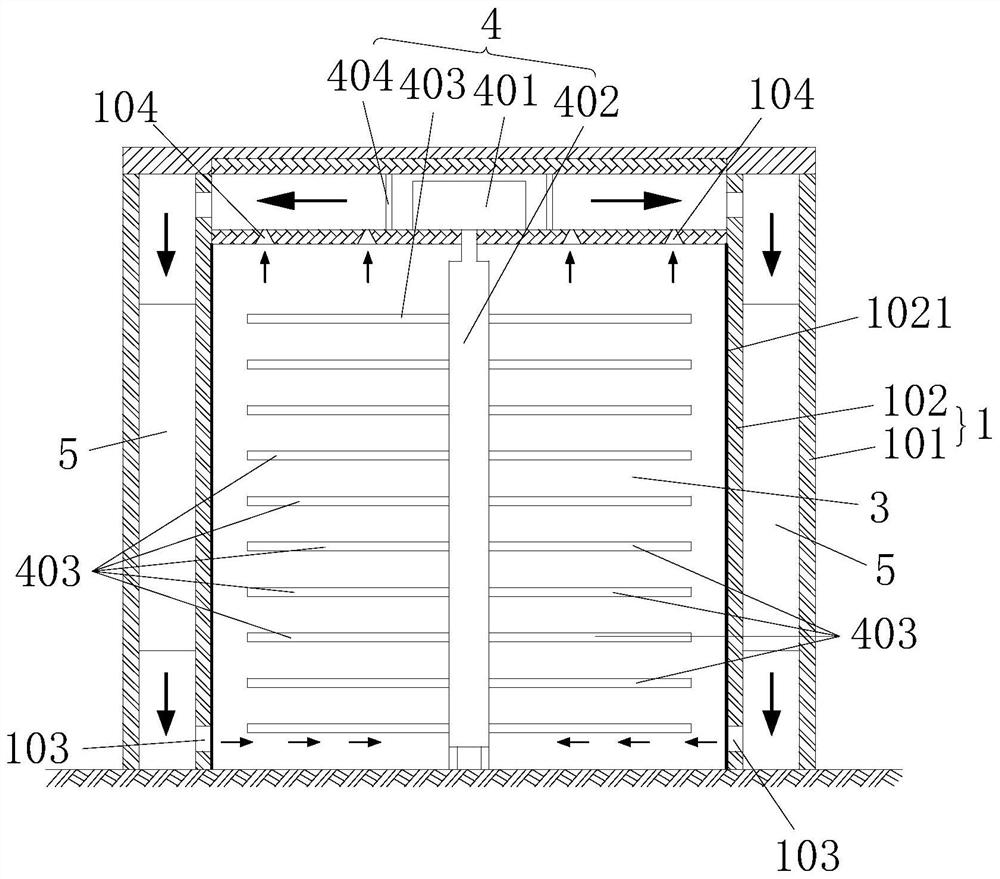

[0028] figure 1 It is the structural schematic diagram of the drying room for drying tea bricks with air intake at the bottom of the inner wall body according to the preferred embodiment of the present invention;

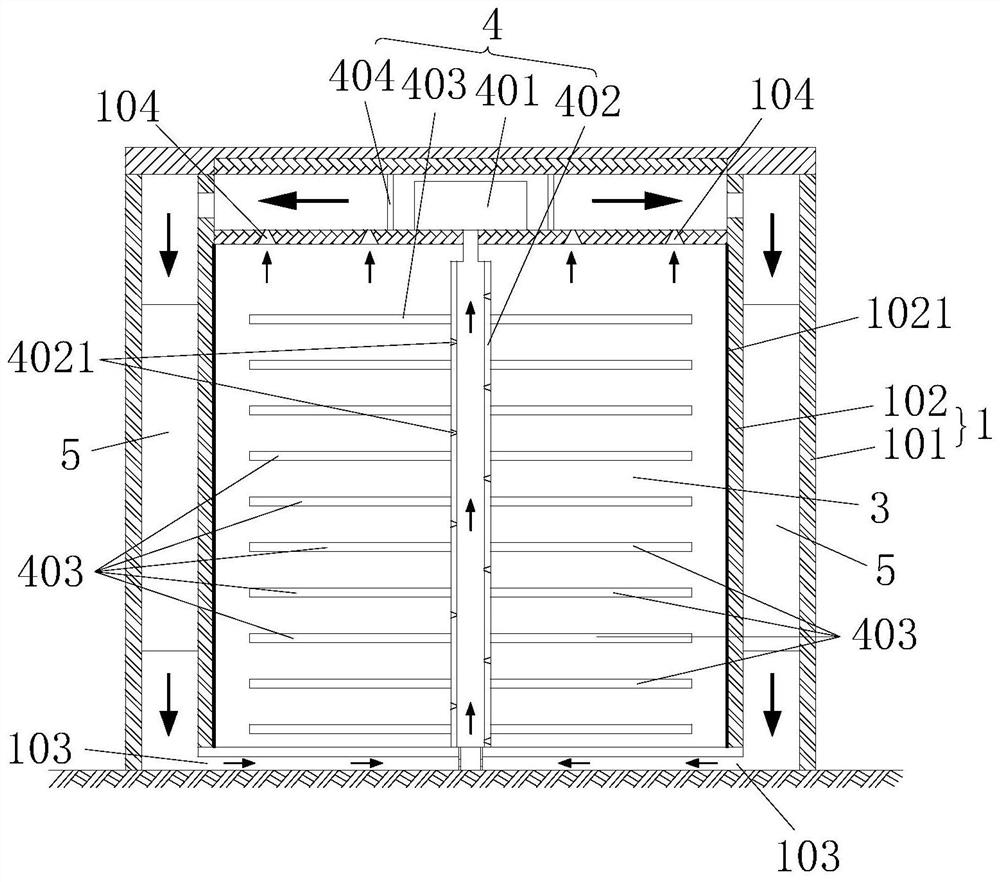

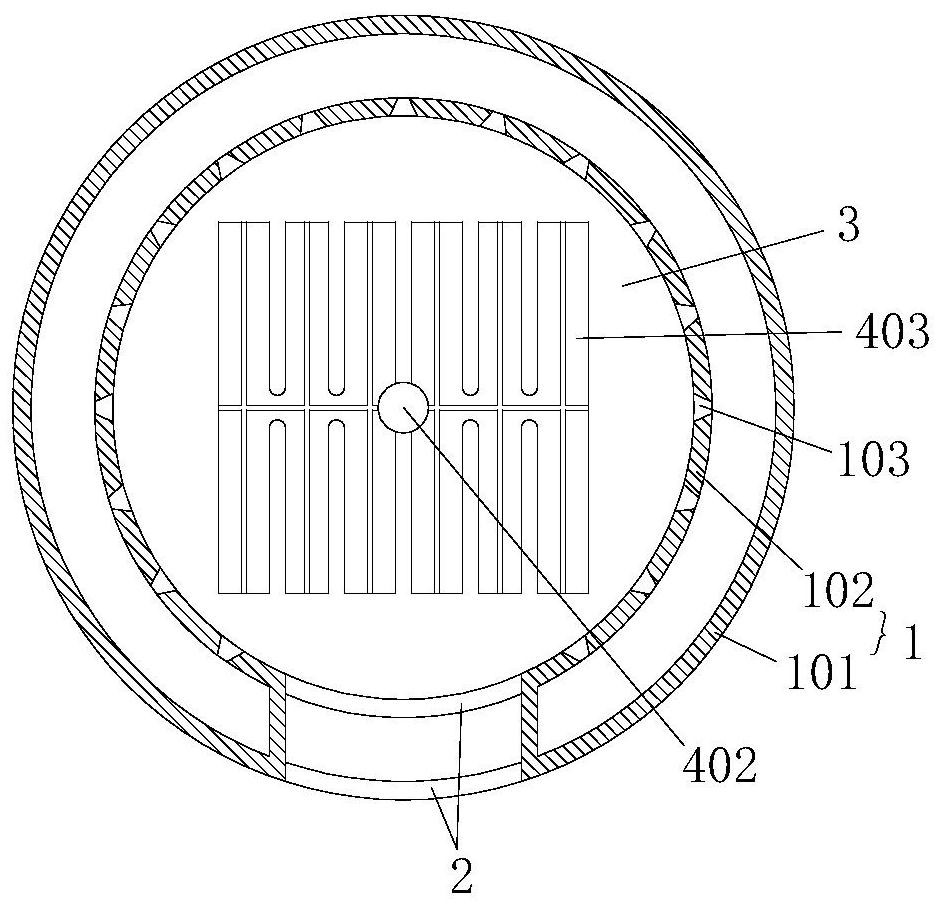

[0029] figure 2 It is a schematic structural diagram of the drying room for tea brick flower drying with ventilation channels arranged at the bottom of the house body and air intake through the transmission shaft according to the preferred embodiment of the present invention; image 3 It is a cross-sectional structural schematic diagram of a drying room for drying tea bricks with flowers in a preferred embodiment of the present invention; Figure 4 It is a schematic structural diagram of a sector-shaped unit frame plate according to a prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com