Transformer substation thermodetector

A technology for thermometers and substations, applied in the field of thermometers, can solve the problems of low temperature measurement efficiency of electrical equipment, endangering the reliable operation of substations, and heavy workload, so as to achieve real-time temperature monitoring, fast and efficient temperature monitoring, and operation Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

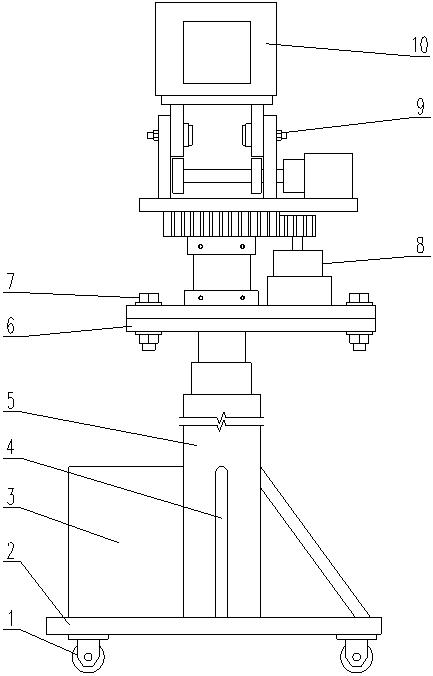

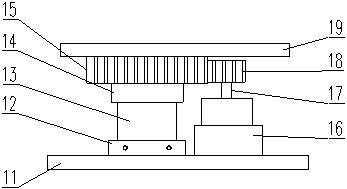

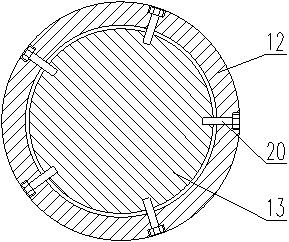

[0020] Such as Figure 1-4 As shown, the substation temperature measuring instrument includes a base plate 2, an electric lifting rod 5 and an electric box 3 are fixedly arranged on the base plate 2, and a lifting rod top plate 6 is fixedly connected to the top of the electric lifting rod 5. The top of the rod top plate 6 is provided with a horizontal adjustment mechanism 8, and the top of the horizontal adjustment mechanism 8 is provided with an elevation adjustment mechanism 9, and the top of the elevation adjustment mechanism 9 is provided with a thermal imaging temperature measurement camera 10; the horizontal adjustment mechanism 8 includes a connecting top plate 11. The connecting top plate 11 is fixedly provided with a connecting base 12 and a first driving motor 16, and the connecting base 12 is fixedly connected with a supporting column 13, and the top of the supporting column 13 is rotatably connected with a connecting top seat 14, and the connecting The top of the t...

Embodiment 2

[0023] Such as Figure 1-4 As shown, the substation temperature measuring instrument includes a base plate 2, an electric lifting rod 5 and an electric box 3 are fixedly arranged on the base plate 2, and a lifting rod top plate 6 is fixedly connected to the top of the electric lifting rod 5. The top of the rod top plate 6 is provided with a horizontal adjustment mechanism 8, and the top of the horizontal adjustment mechanism 8 is provided with an elevation adjustment mechanism 9, and the top of the elevation adjustment mechanism 9 is provided with a thermal imaging temperature measurement camera 10; the horizontal adjustment mechanism 8 includes a connecting top plate 11. The connecting top plate 11 is fixedly provided with a connecting base 12 and a first driving motor 16, and the connecting base 12 is fixedly connected with a supporting column 13, and the top of the supporting column 13 is rotatably connected with a connecting top seat 14, and the connecting The top of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com