Fault prediction analysis method and model of industrial production equipment

A technology for industrial production equipment and fault prediction, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., to solve problems such as failure cause analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

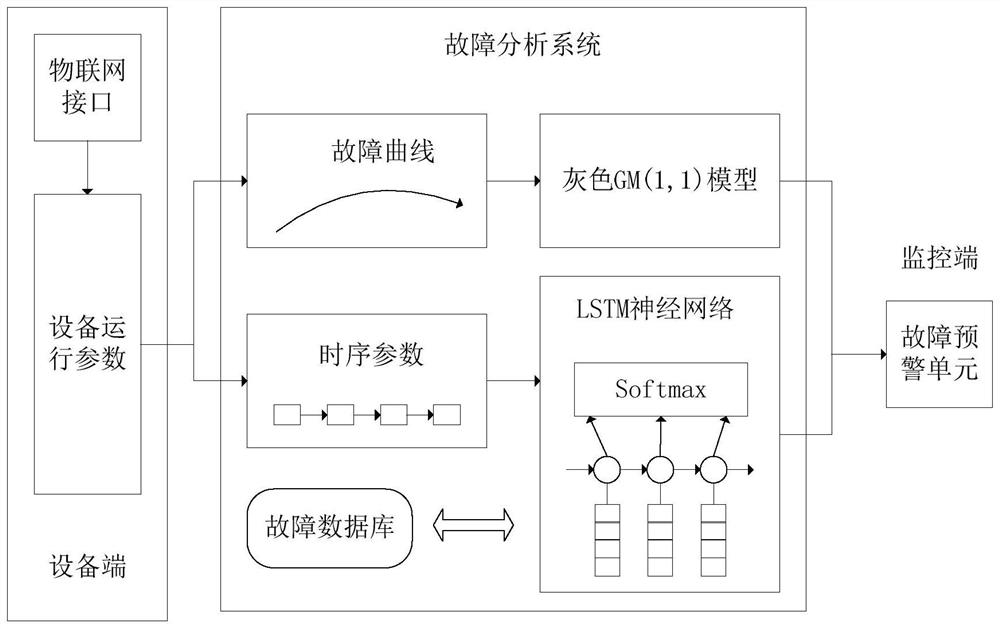

[0047]SeeFigure 1-2The present invention provides a technical solution: a fault prediction analysis method for industrial production equipment, including the following steps:

[0048]Step S1: Divide the device level and collect operational data; to collect the failure rate, fault category, fault cause of the general equipment; run data for critical equipment, real-time acquisition equipment;

[0049]Step S2: Performing a device failure prediction analysis; step S2.1 on the general device is performed, and step S2.2 is performed on the critical device;

[0050]Step S2.1: Perform a general equipment fault prediction;

[0051]Step S2.1.1: Set the original timing characteristics x(0)= (X(0)(1), x(0)(2), ..., x(0)(n)), using gray system theory to make a weighted accumulation, generate new data sequences: X(1)= (X(1)(1), x(1)(2), ..., x(1)(n)), where0 <α <1 is a distance weight;

[0052]Step S2.1.2: The background value of the GM (1, 1) model is Z(1)= (Z(1)(2), Z(1)(3), ..., z(1)(n)), where Z(1)(k) = 0....

no. 2 example

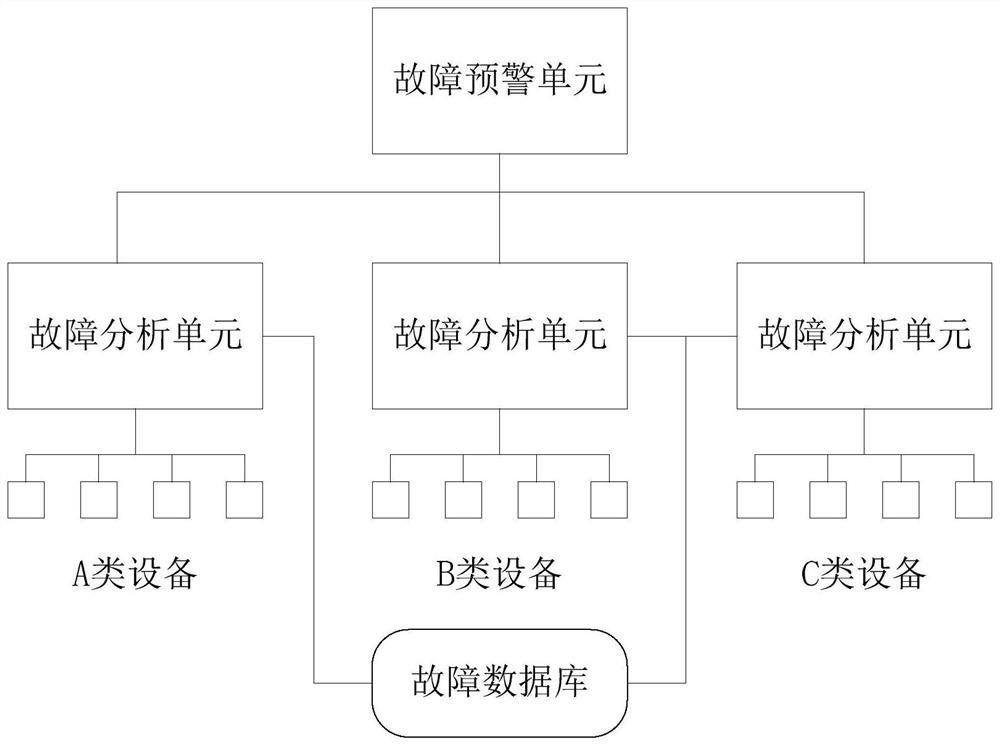

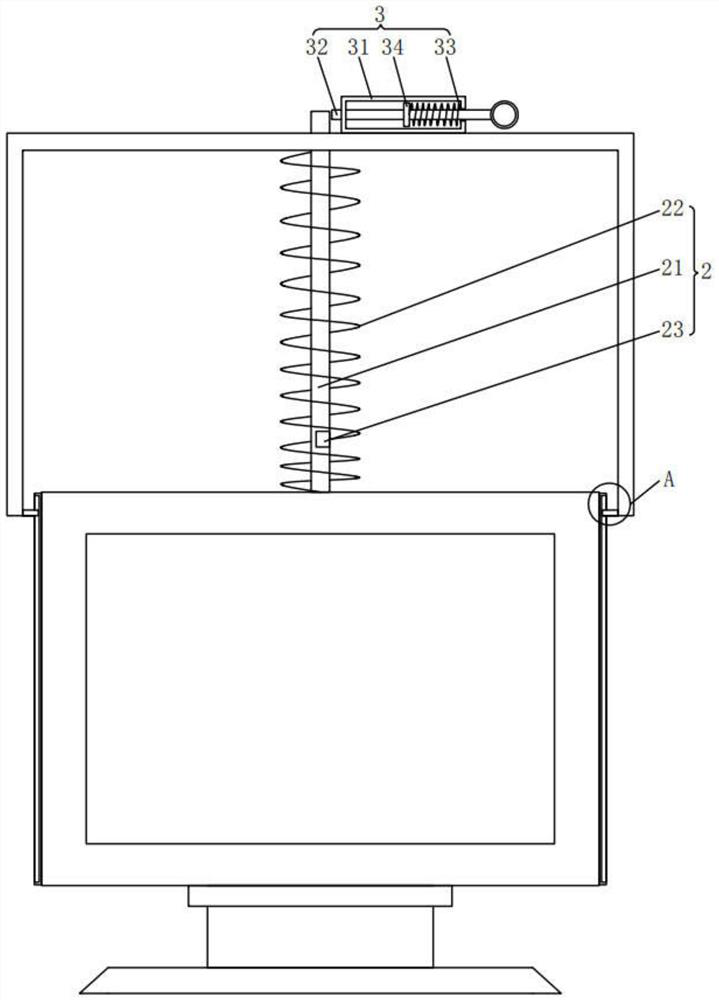

[0089]Seeimage 3 ,Figure 4 , A fault prediction analysis model of an industrial production apparatus according to the first embodiment of the present application, and the second embodiment of the present application proposes another industrial production equipment fault prediction analysis model. The second embodiment is merely the preferred embodiment of the first embodiment, and the implementation of the second embodiment will not affect the separate implementation of the first embodiment.

[0090]Specifically, the fault prediction analysis model of the industrial production apparatus according to the second embodiment of the present application is that the failure prediction analysis model of industrial production equipment, further includes a display screen protection device for the device operation parameter display. 1, the guard 1 includes a fixing plate 11, and the inside of the fixing plate 11 has a slide groove 12, and the inside of the slide groove 12 is slidably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com