Preparation method of lithium-air battery based on gel electrolyte-lithium negative electrode integrated structure

A technology of gel electrolyte and lithium-air battery, which is applied in the direction of electrical components, secondary batteries, battery electrodes, etc., can solve the problems that the electrolyte and the lithium negative electrode cannot be fully contacted, the lithium negative electrode is fatigued and easy to break, and there are potential safety hazards. Device interface problems, solving fatigue fracture problems, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

[0029] The preparation method of the lithium-air battery based on the gel electrolyte-lithium negative electrode integrated structure provided in this embodiment specifically includes the following steps:

[0030] Step 1: Weld the nickel tabs on the nickel foam by spot welding with a spot welding machine as a lithium negative electrode current collector. The size of the nickel foam is: length × width × thickness = 3cm × 5cm × 0.1cm, and the spot welding current 20mA;

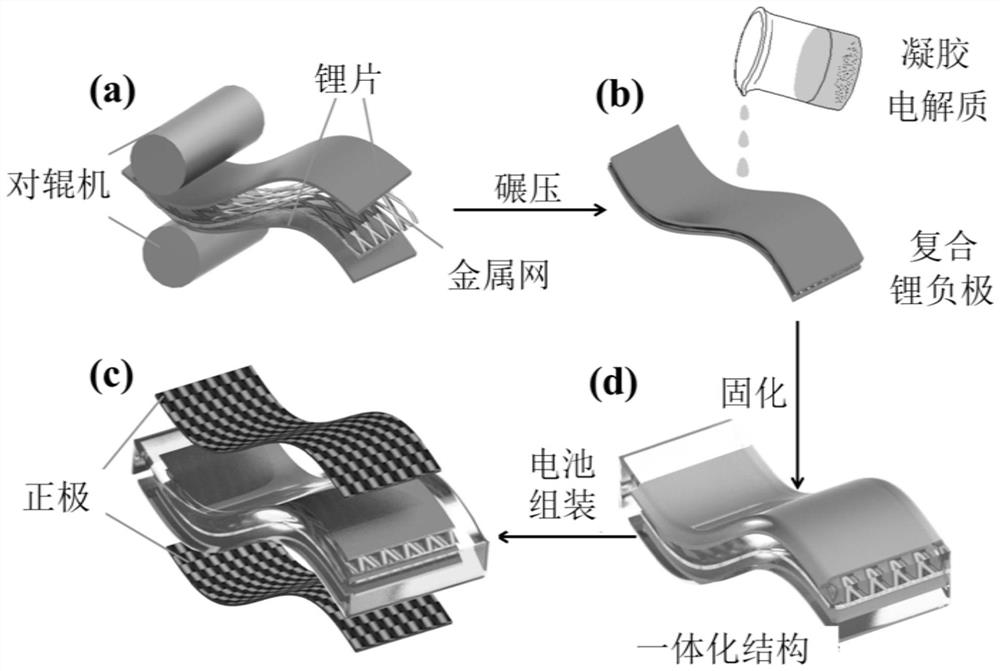

[0031] Step 2: If figure 1 As shown in (a), the lithium negative electrode current collector obtained in step 1 is implanted into the lithium negative electrode composed of two lithium sheets by means of double-roller rolling, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com