Motor, compressor and refrigeration equipment

A stator and gear shoe technology, applied in the field of refrigeration equipment, can solve problems such as the inability to meet the needs of silence, and achieve the effects of reducing local saturation effects, increasing magnetic circuit pressure drop, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

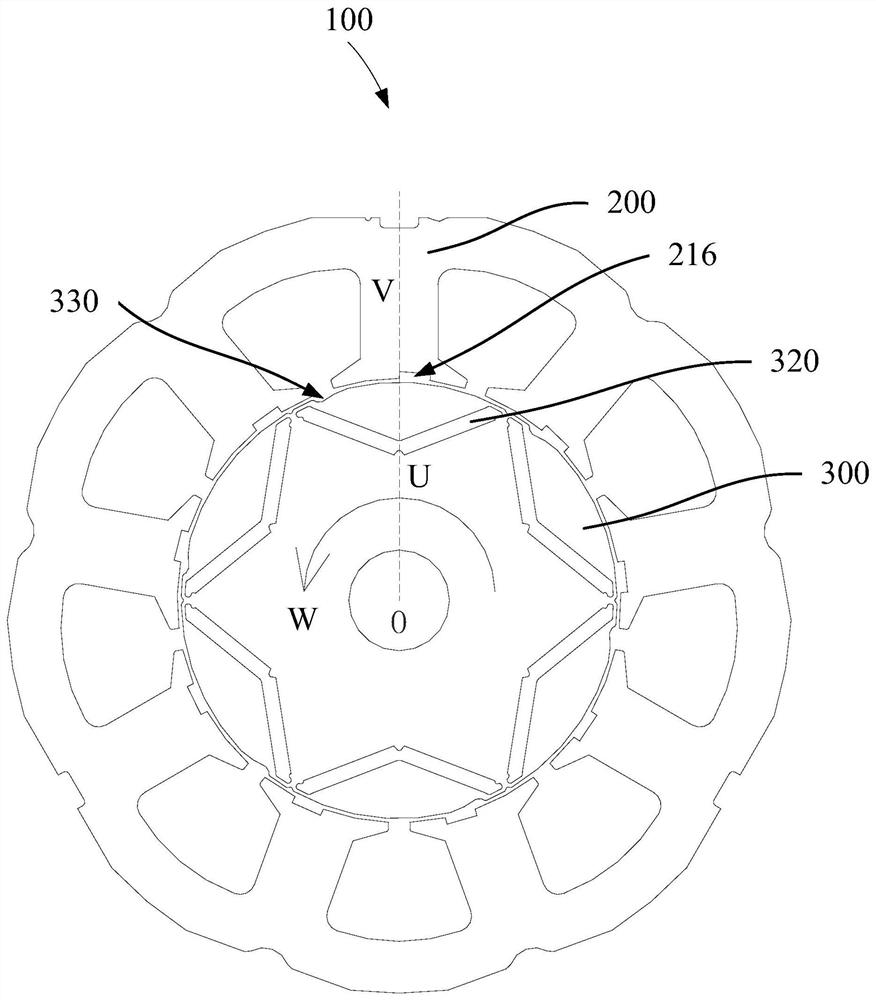

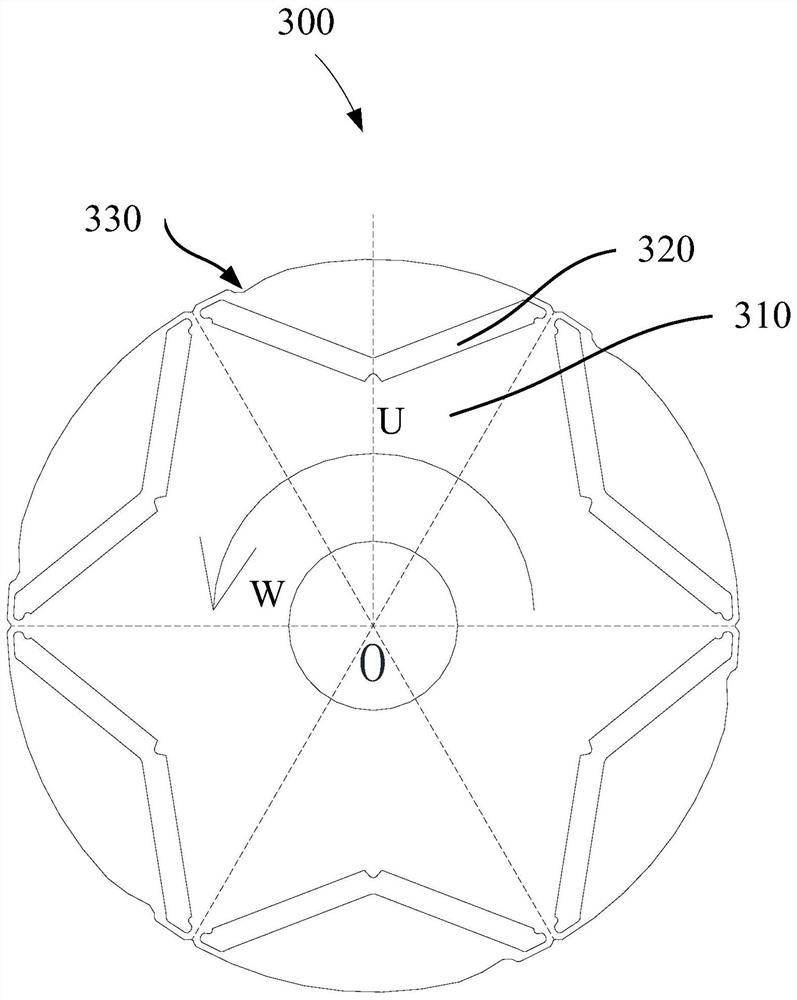

[0066] Such as Figure 1 to Figure 7 As shown, according to the first aspect of the present invention, the present invention provides a motor 100, the motor 100 includes: a stator 200 and a rotor 300, the stator 200 includes a stator inner hole 240, and the rotor 300 can rotate in the stator inner hole 240.

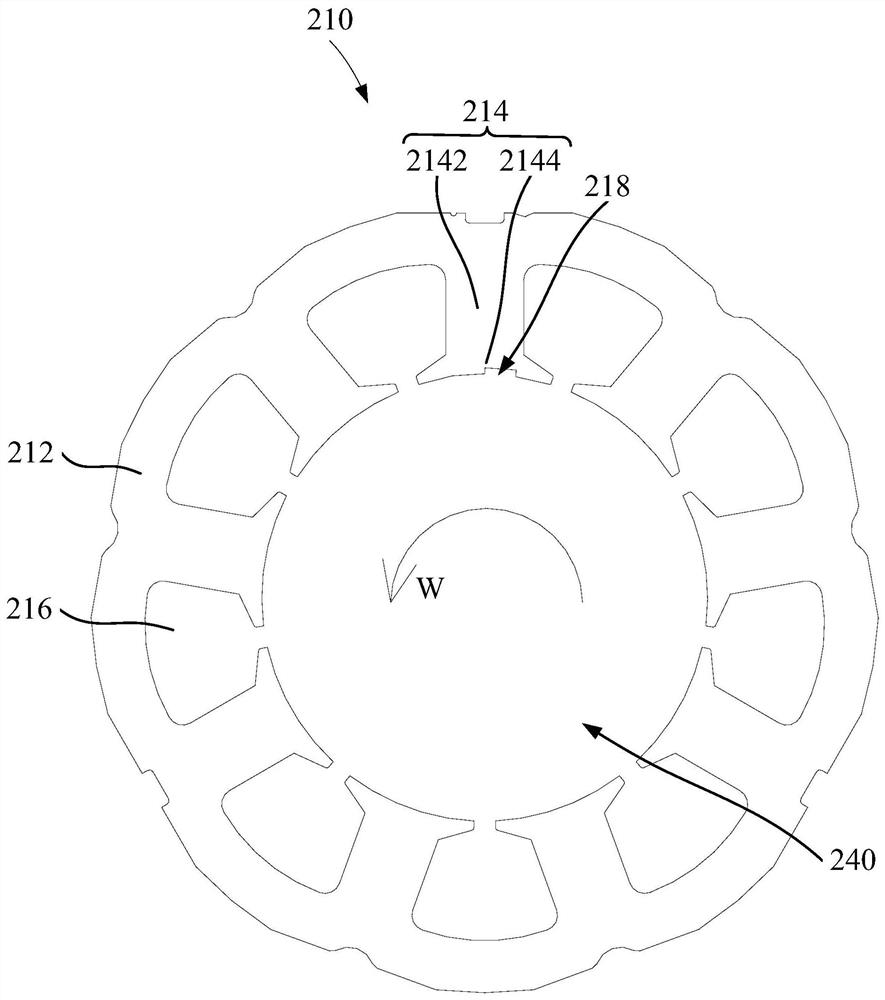

[0067] Wherein, the stator 200 includes: a first stator punching piece 210, and the first stator punching piece 210 includes: a first stator yoke 212 and a first stator tooth 214, wherein the first stator yoke 212 is a ring structure, There are multiple first stator teeth 214 , and the multiple first stator teeth 214 are evenly distributed on the inner ring of the first stator yoke 212 .

[0068] Moreover, a first stator slot 216 is formed between adjacent first stator teeth 214, and a winding can be arranged in the first stator slot 216. A plurality of first stator teeth 214 surround a stator inner hole 240, and the rotor 300 rotates around first plurality of stator tee...

Embodiment 2

[0080] Such as figure 1 and figure 2 As shown, on the basis of Embodiment 1, further, along the circumferential direction of the stator 200, the first magnetic guide part 218 deviates from the first tooth part 2142 and faces the contour line of the second end 280 of the first tooth shoe 2144, The shortest distance between the second end 280 of the first tooth shoe 2144 is greater than the contour line of the first magnetic guide part 218 away from the first tooth part 2142 and towards the first end 270 of the first tooth shoe 2144, and the first The shortest distance between the first ends 270 of the tooth shoes 2144.

[0081] That is, the shortest distance between the first magnetic guide part 218 and the second end 280 of the first tooth shoe 2144 is greater than the shortest distance between the first magnetic guide part 218 and the first end 270 of the first tooth shoe 2144 .

[0082] In this embodiment, along the circumferential direction of the stator 200 , relative t...

Embodiment 3

[0085] Such as figure 1 and figure 2 As shown, on the basis of Embodiment 1 or Embodiment 2, further along the circumferential direction of the stator 200 , the first magnetic guide part 218 is away from the first tooth part 2142 and faces the second end 280 of the first tooth shoe 2144 The shortest distance between the contour line of the first tooth shoe 2144 and the second end 280 of the first tooth shoe 2144 is greater than the contour line of the first magnetic guide part 218 away from the first tooth part 2142 and toward the second end 280 of the first tooth shoe 2144 , the shortest distance from the first end 270 of the first tooth shoe 2144 . That is, the first magnetic guide portion 218 is located on a side where the center line of symmetry of the first tooth portion 2142 is away from the rotation direction of the rotor 300 .

[0086] That is, the shortest distance between the first magnetic guide part 218 and the second end 280 of the first tooth shoe 2144 is grea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap