Adjustable permanent magnet coupler

A permanent magnet coupling and adjustable technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electromechanical device, etc., can solve the problems of complex structure and difficult speed regulation, and achieve convenient speed regulation and simple structure , The effect of non-contact manual speed adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

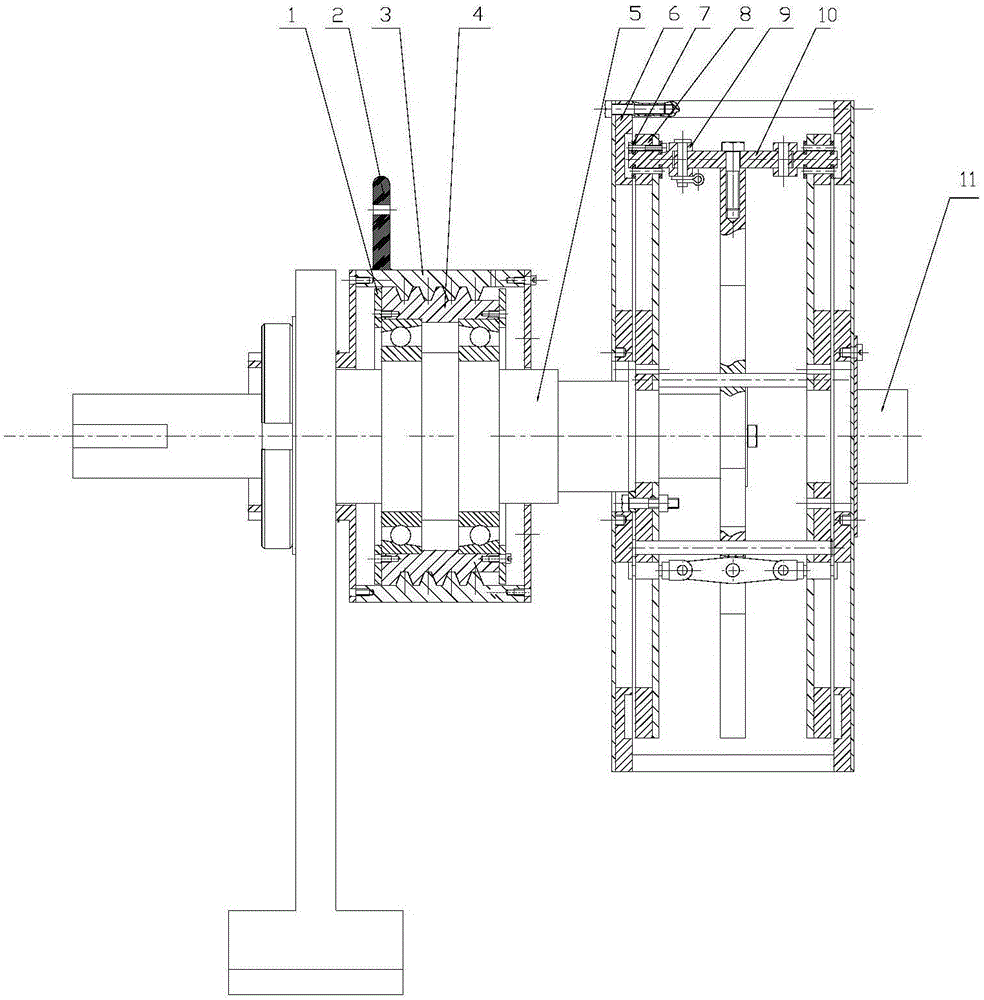

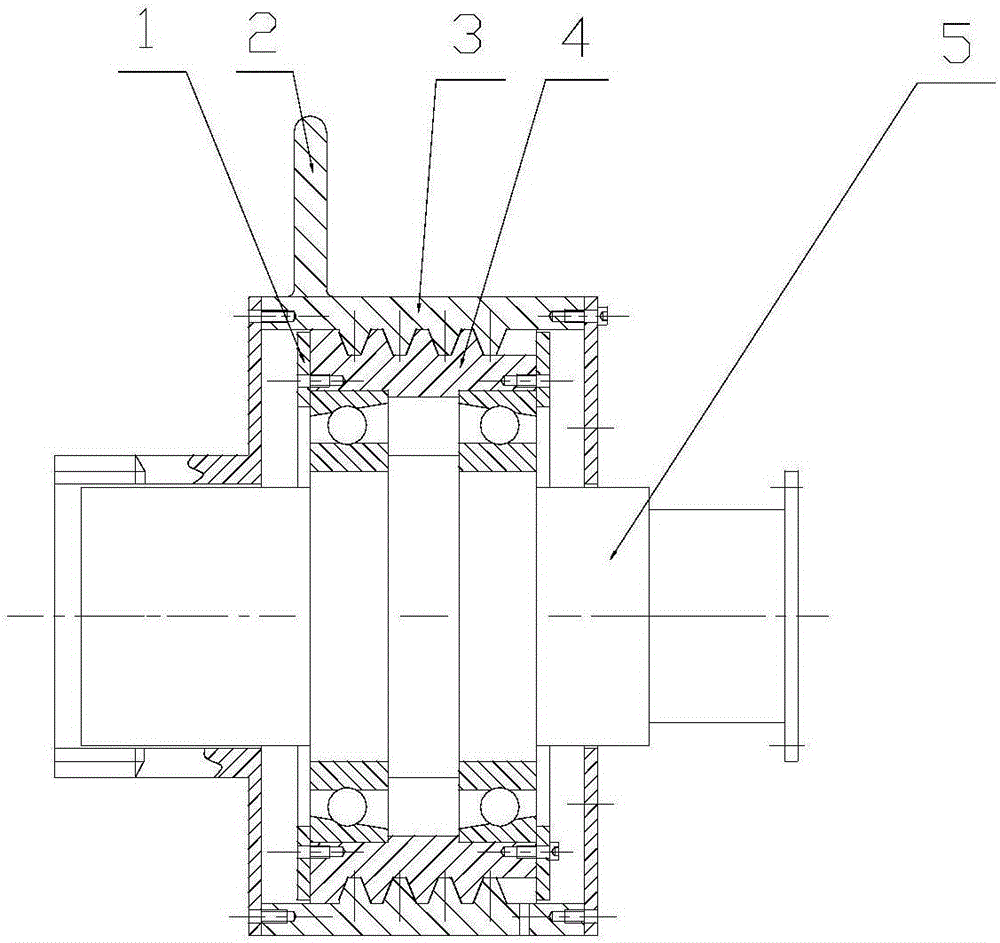

[0025] see figure 1 , the adjustment mechanism of the adjustable shaft coupling provided by the present invention manually rotates the handle 2, and the outer cylinder 3 produces a rotational displacement and transmits it to the inner cylinder 4 through a screw thread, and the inner cylinder side cover 1 fixed on the inner cylinder 4 pushes the bearing outer sleeve As a result, the stepped shaft 5 is driven to move toward the coupling, and the inner rotor 8 connected to the stepped shaft 5 through the bolts is displaced in the same direction, and then the inner rotor 8 is shrunk inward through the fork 9 and the adjusting frame 10, thus changing the The air gap between the outer rotor 7 and the inner rotor 8 changes, and the eddy current effect is generated to drive the output shaft connector 11 connected to the outer rotor 6 by bolts to rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap