Can lid

A can lid and scoring line technology, which is applied in the field of fully-opening can lids, can solve the problems of irregular cutting of the scoring line, large opening force, etc., achieve good lid opening performance, improve bending rigidity, and good lid opening performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

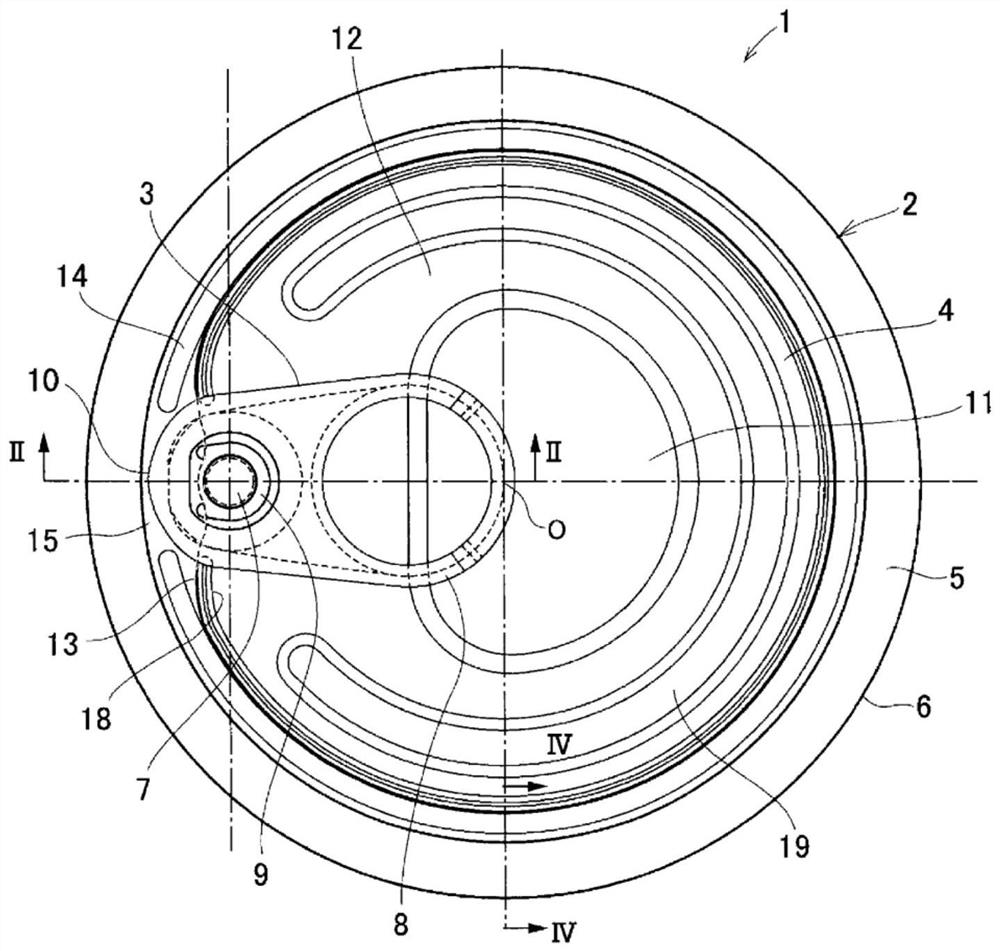

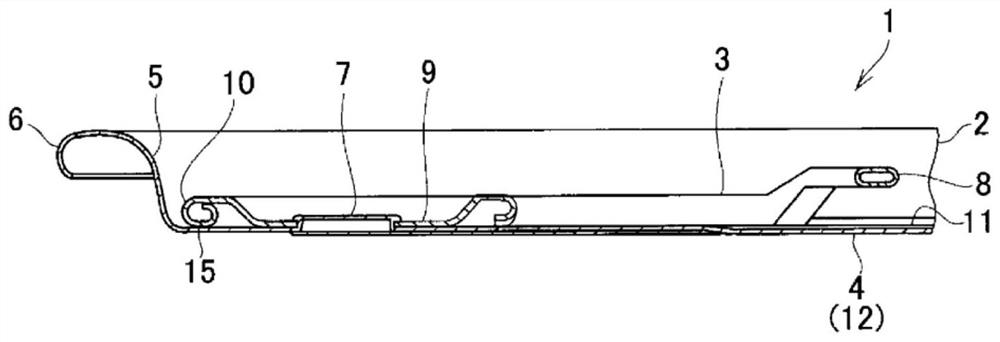

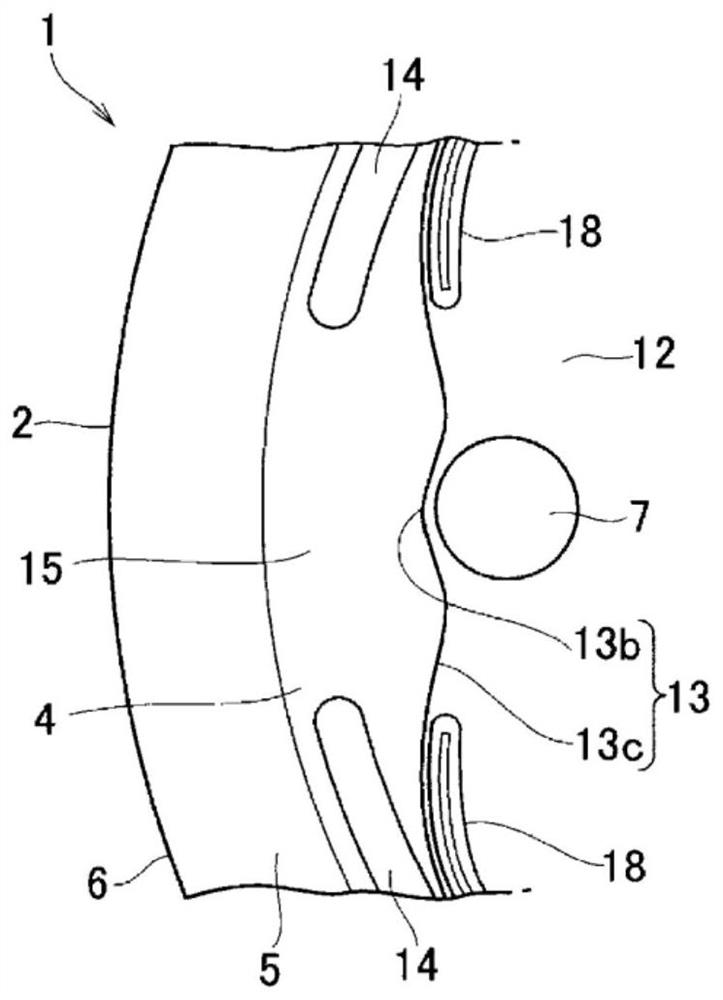

[0034] The can end of the present invention is a so-called full opening type can end. A panel portion is provided at the center of the main body portion attached (wrapped around) to the can, and an opening piece is formed by scoring lines so as to occupy most of the panel portion. A protruding piece is attached to a part of the peripheral portion of the opening piece by a rivet. Finger hooks are provided on the tabs. When the finger hook is pulled up, an initial break occurs at a part of the score line, and the score line is cut sequentially from the position where the initial break occurs, and finally the cut along the score line is completed on the entire score line. Produced, the opening piece is removed from the body portion, and the can lid is open.

[0035] That is, the can lid 1 of the present invention includes a main body 2 and a protruding piece 3 . exist figure 1 and figure 2 An example of this is shown in . The main body 2 is a disc-shaped member matching th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap