Movable whole-row harvesting device for edible fungi

A harvesting device and mobile technology, which are applied in the field of edible fungi mobile whole-row harvesting devices, can solve the problems of easy scratching of hands and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

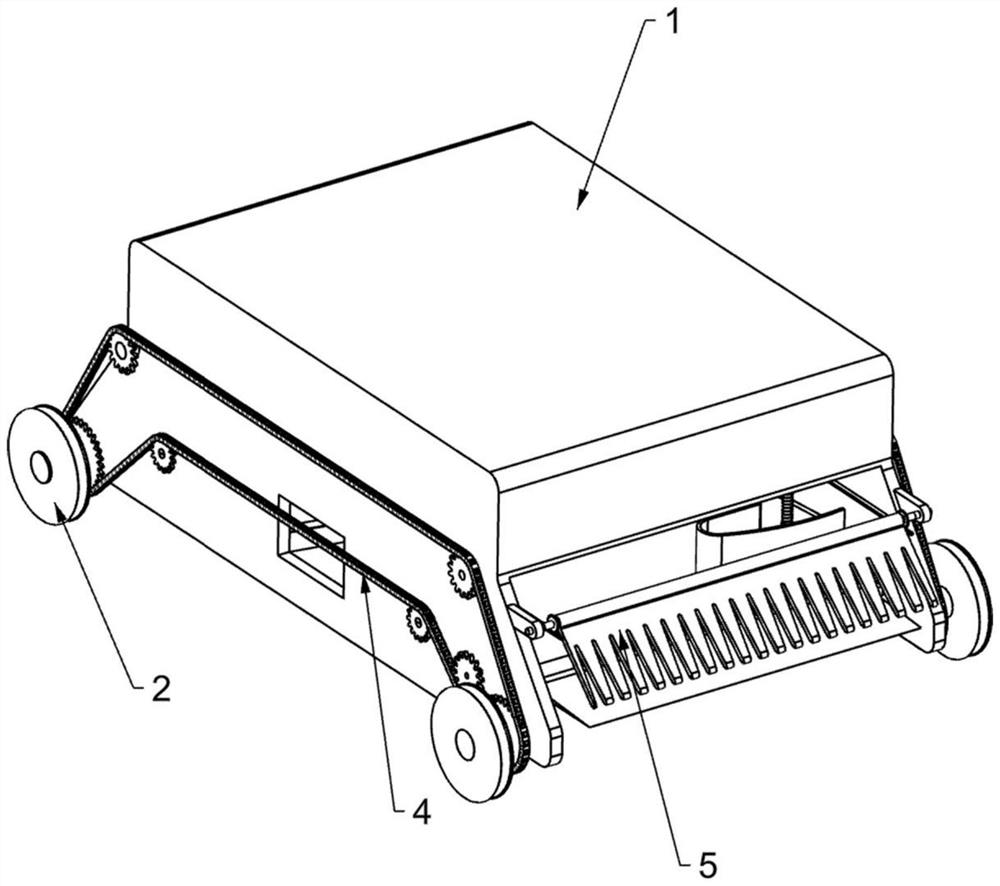

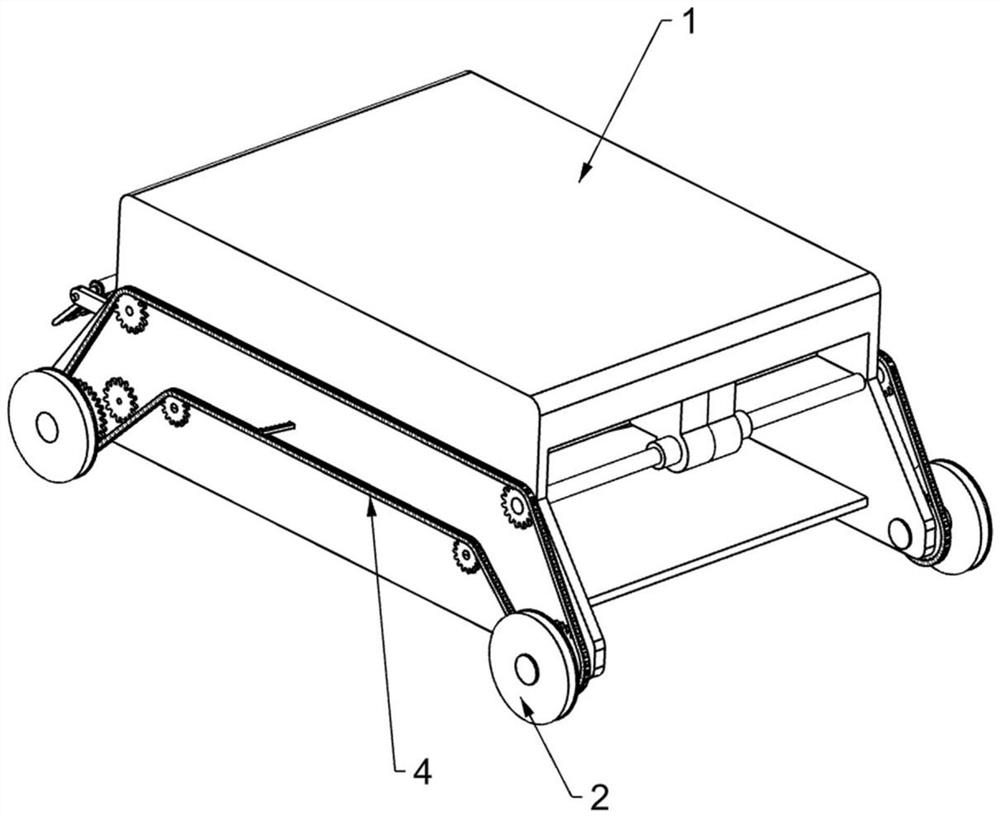

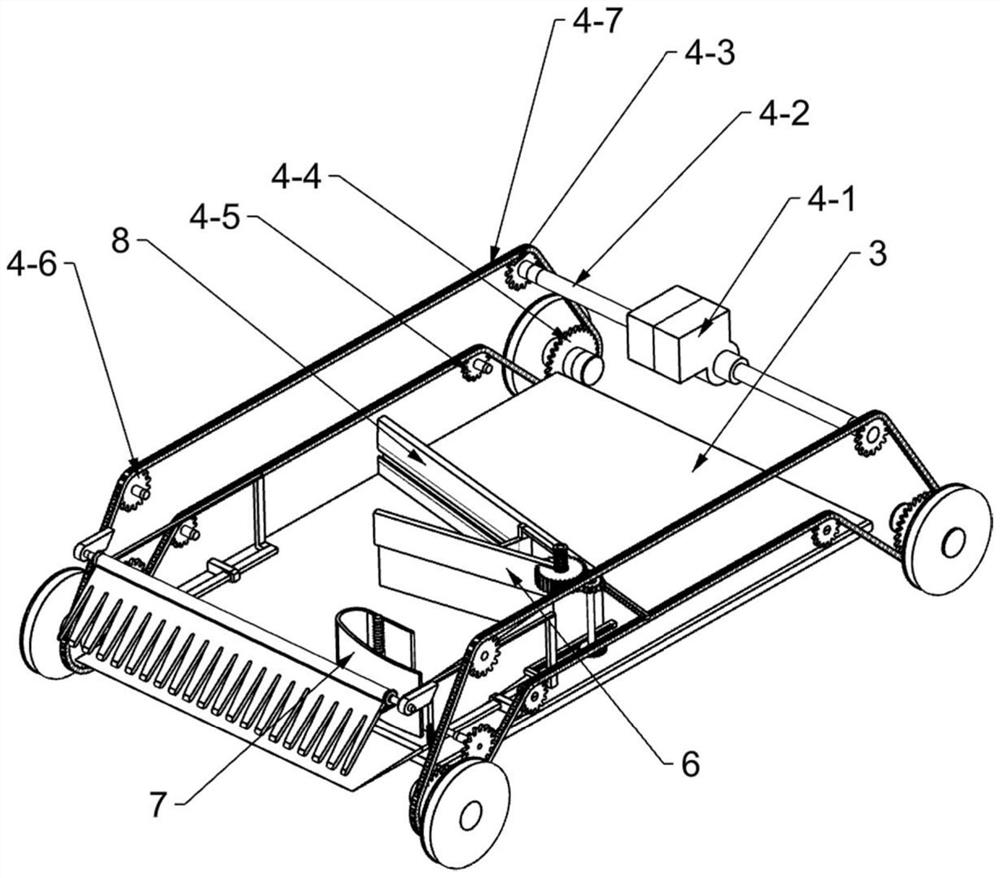

[0025] A mobile whole row harvesting device for edible fungi, such as Figure 1-7 As shown, it includes a connecting frame 1, a moving wheel 2, a support plate 3, a mushroom picking moving mechanism 4, a mushroom cutting mechanism 5 and a mushroom swinging and pushing out mechanism 6, and the symmetrical rotation on both sides of the connecting frame 1 is connected with a moving wheel 2. The number of wheels 2 is four, the inner lower part of the connecting frame 1 is fixedly connected with the supporting plate 3, the mushroom picking moving mechanism 4 is installed on both sides of the connecting frame 1, the mushroom cutting mechanism 5 is installed on one side of the supporting plate 3, and the mushrooms swing The push-out mechanism 6 is installed on the support plate 3 .

[0026] When it is necessary to harvest the entire row of mushrooms, the staff will drive the moving wheel 2 to rotate and move the position of the device by controlling the operation of the mushroom pick...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 5 and Figure 8 As shown, it also includes a swing blocking mechanism 7, and the swing blocking mechanism 7 includes a fixed shaft two 701, a return spring 702 and a swing baffle 703, the fixed shaft two 701 is fixedly connected to the top of the connecting frame 1, and the bottom of the fixed shaft two 701 is rotatable A swing baffle 703 that can prevent the mushrooms that are toggled by the toggle plate 509 from sliding out from one side is connected, and a return spring 702 is fixedly connected between the swing baffle 703 and the connecting frame 1, and the return spring 702 is wound on the fixed shaft 2 701 .

[0035] When the cutter 506 stretches out for cutting, the swing plate 608 will swing outwards, and then the swing plate 608 will push the swing baffle plate 703 to swing outwards. When the swing plate 608 swings back to push the cut mushrooms, The swing baffle 703 will also swing back to push the mushrooms under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com