Linear cutting anastomat with pre-pressed tissue thickness feedback prompt function

A feedback prompt, tissue thickness technology, applied in the field of staplers, can solve the problems of tissue damage and anastomosis failure, prone to wrong selection of staple cartridge specifications, lack of tissue thickness judgment prompts, etc., to reduce bleeding, tissue damage and the possibility of necrosis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

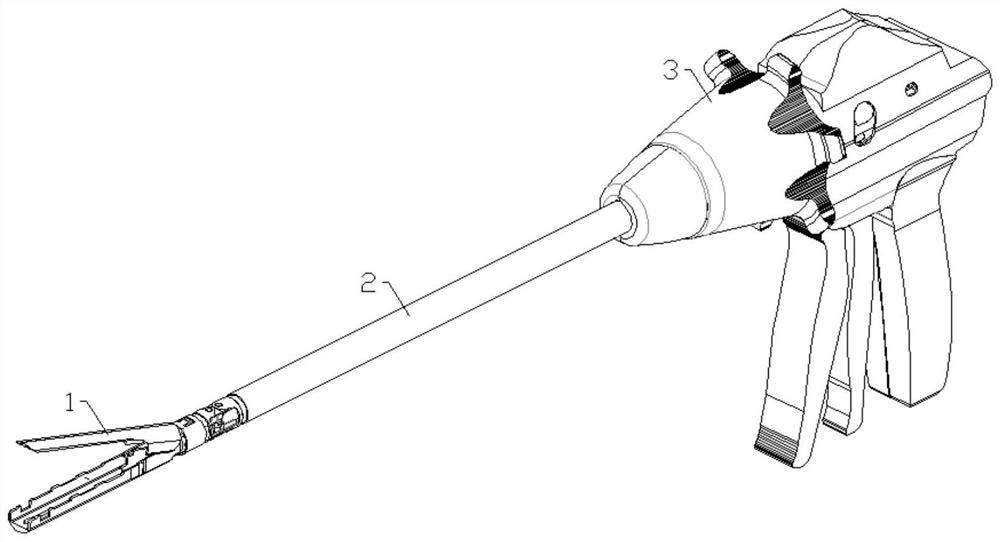

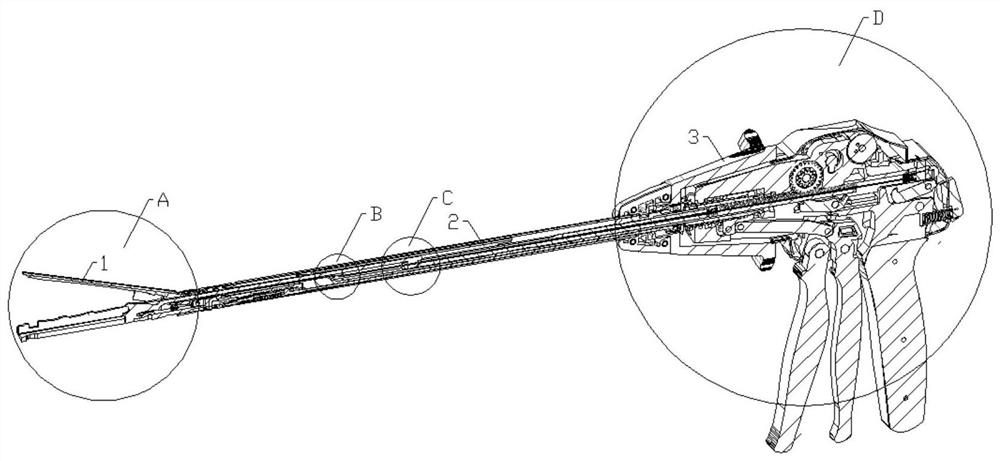

[0025] Such as Figure 1-8 As shown, a linear cutting stapler with a pre-compressed tissue thickness feedback prompt function includes a staple cartridge seat assembly 1, a sleeve assembly 2, and a gun body assembly 3. The staple cartridge seat assembly 1 is provided with an induction device 4 for use in Inducting the opening angle of the nail cartridge seat assembly 1; the gun body assembly 3 is provided with a display device 8 for displaying the data sensed by the induction device 4; 2 for transmitting the data sensed by the sensing device 4 to the display device 8 .

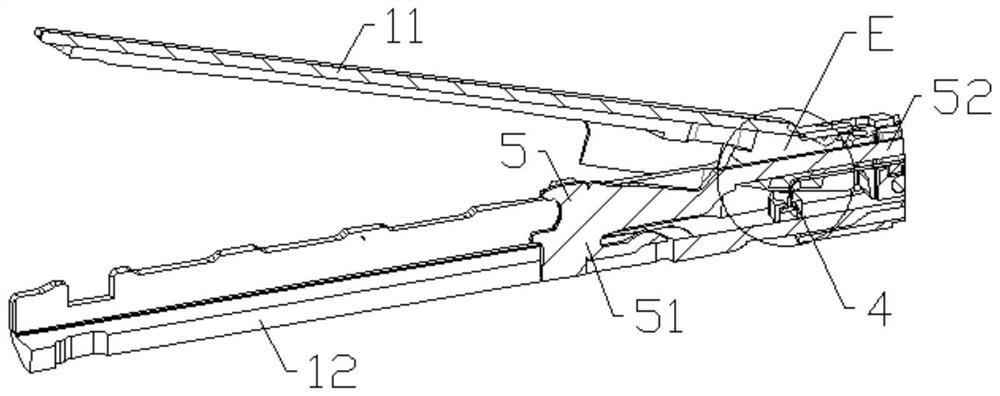

[0026] The magazine base assembly 1 includes a nail anvil 11 and a nail magazine base 12 , and the sensing device 4 is used for sensing the angle between the nail anvil 11 and the nail magazine base 12 .

[0027] Described induction device 4 comprises the fixed sleeve 41 that is arranged on the opposite surface of the junction of nail box base 12 and nail anvil 11, and the induction block 42 of the cylindrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com