Cloth bag dust removal device

A technology of bag dust removal and dust removal box, which is applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of not being able to know the situation of the bag in time, dust cannot be cleaned, etc., and achieve outstanding resilience, good effect, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

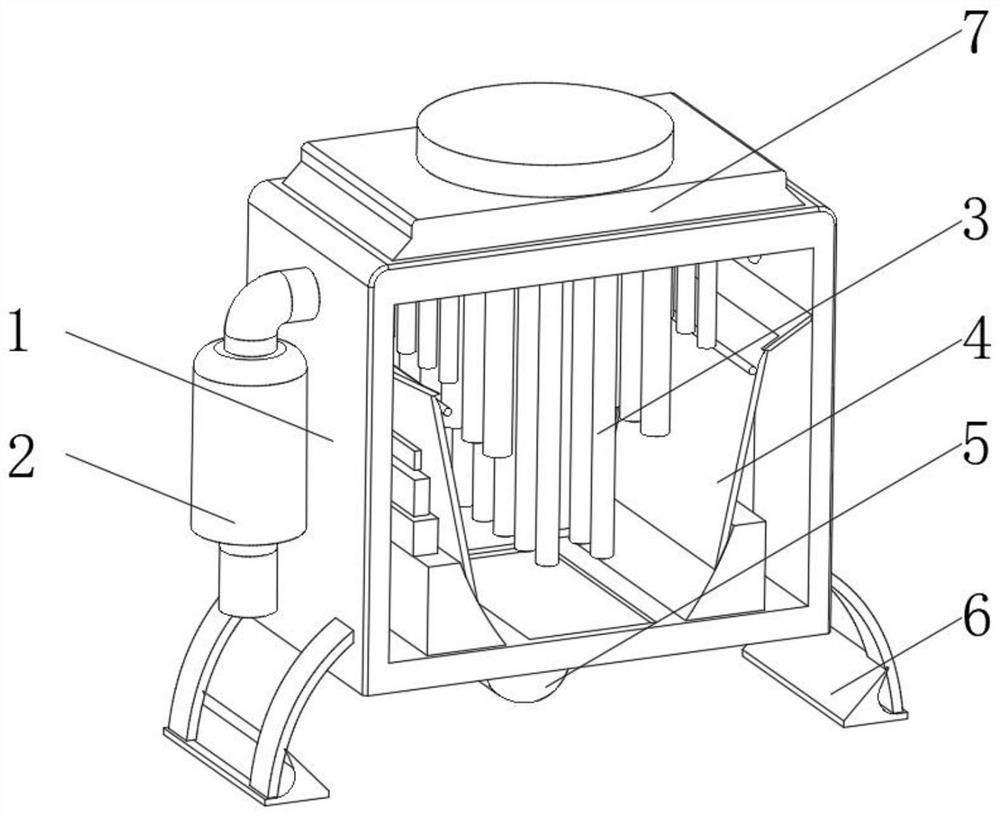

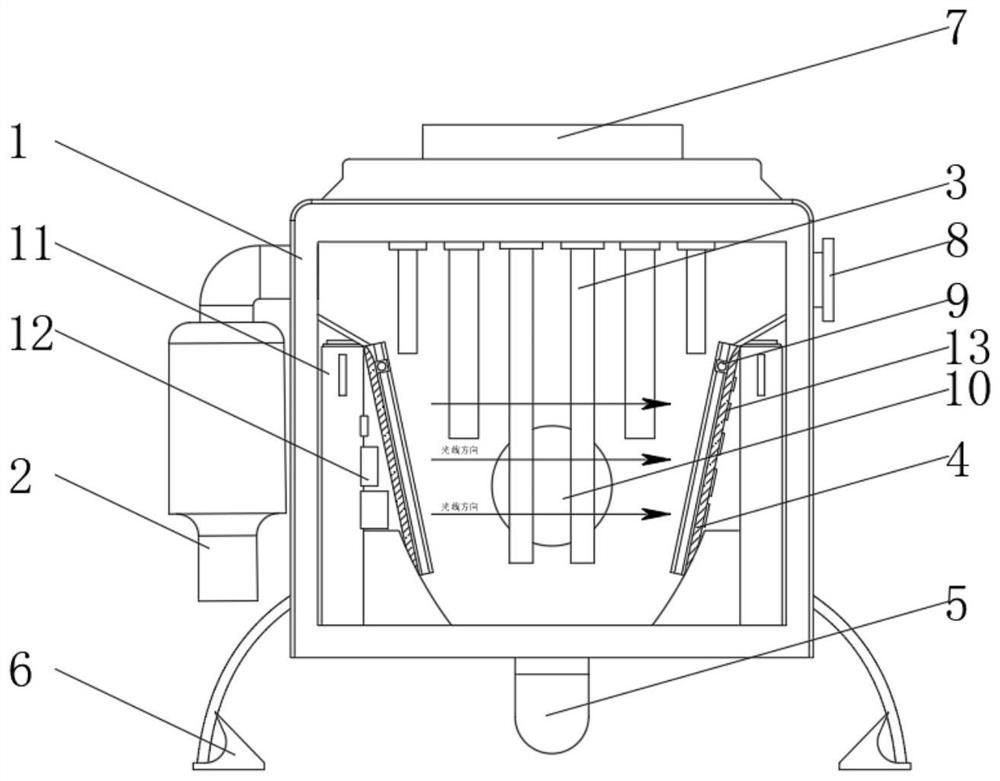

[0033] see Figure 1-3 , the present invention provides a technical solution: a bag dust removal device, including a dust removal box 1 and an air intake device 2, a dust removal bag 3 is installed above the inside of the dust removal box 1, and dust sloping plates 4 are arranged on both sides of the dust removal box 1, and the dust removal The outer bottom of the box 1 is fixedly connected with a support tripod 6, the top of the dust removal box 1 is provided with a main controller 7 of the dust collector, the top of the air intake device 2 is connected with the dust removal box 1 through an air intake pipe, and the bottom of the dust removal box 1 is installed with a bottom exhaust pipe 5, The upper side of the dust removal box 1 away from the air intake device 2 is provided with an upper and outer exhaust pipe 8, and the rear side of the dust removal box 1 is provided with an inspection port 10, and the two sides of the dust removal box 1 are fixedly connected with the inner...

Embodiment example 2

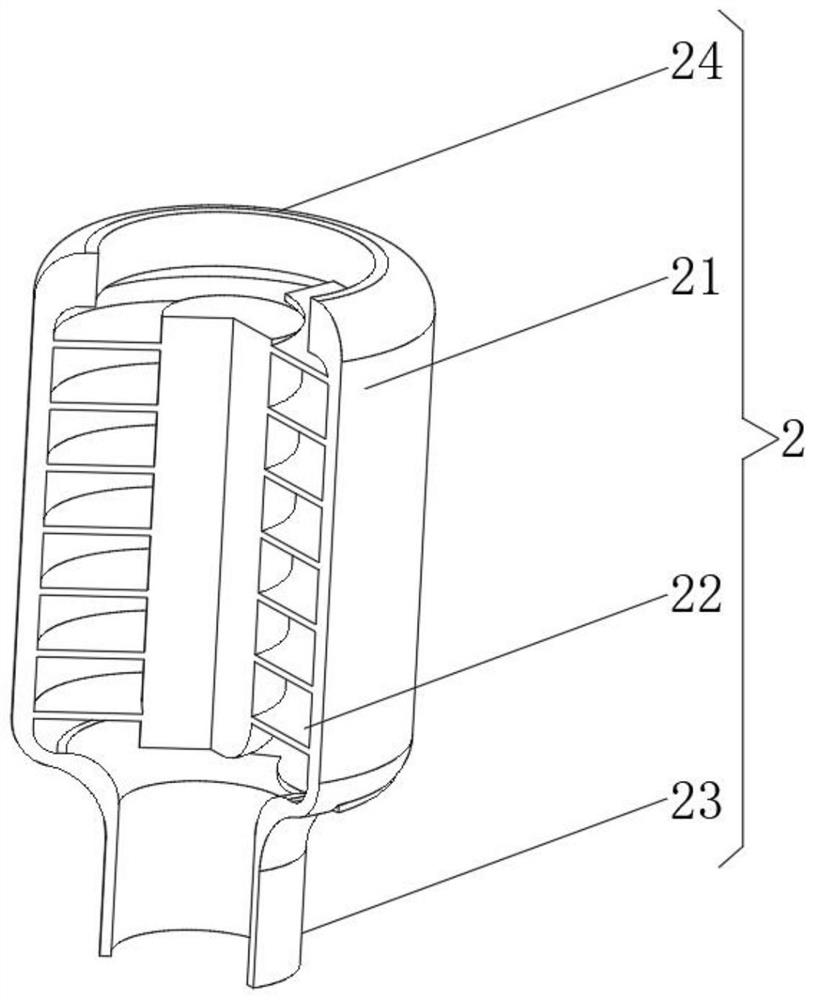

[0037] see Figure 1-5 , on the basis of the implementation case 1, the present invention provides a technical solution: the cleaning device 9 includes a central roller 91 and an outer cleaning roller 92, a central inner column 93 is arranged at the middle position of the central roller 91, and the outer side of the central inner column 93 is connected to the outer cleaning roller 92. The inner side of the cleaning roller 92 is respectively provided with an inner turning arm 94 and an outer turning arm 95, and one end of the inner turning arm 94 away from the center inner column 93 is rotatably connected with the outer turning arm 95, and an elastic spring is installed between the inner turning arm 94 and the outer turning arm 95. Telescopic rod 96, the two ends of the elastic telescopic rod 96 are respectively connected with the inner rotating arm 94 and the outer rotating arm 95. By setting the cleaning device 9, the inclined surface will be cleaned. Its position on the outs...

Embodiment example 3

[0041] see Figure 1-6 , on the basis of the implementation case 1 and the implementation case 2, the present invention provides a technical solution: the wetting device 14 includes an inner solvent chamber 141, an outer roller 142 is installed on the outside of the inner solvent chamber 141, and an arc is installed on the inner side of the inner solvent chamber 141. The outer roller 142 is installed on the arc-shaped inner bullet frame. When the wetting device 14 is subjected to a strong extrusion force, the outer roller 142 shrinks inward, and the internal solvent flows out. , with the cleaning component can effectively clean the inclined plate, and can also increase the cleaning effect.

[0042] The outer cleaning rollers 92 are arranged in three pieces, and there are gaps between the outer cleaning rollers 92 , and the outer cleaning rollers 92 are evenly arranged on the outer side of the central roller 91 .

[0043] When in use, the dust is injected into the dust removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com