Multi-stage crushing device for building processing

A crushing device and building technology, which is applied in grain processing and other fields, can solve the problems that the crushing efficiency needs to be improved, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

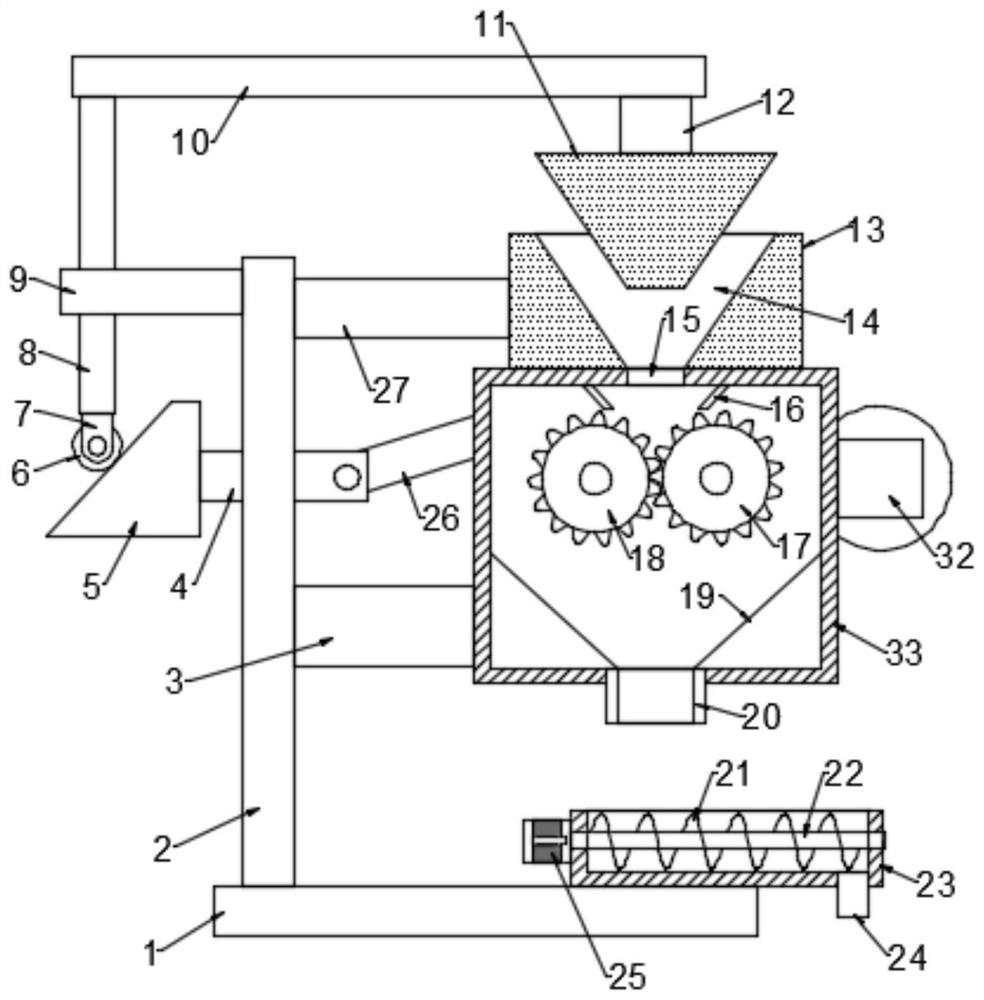

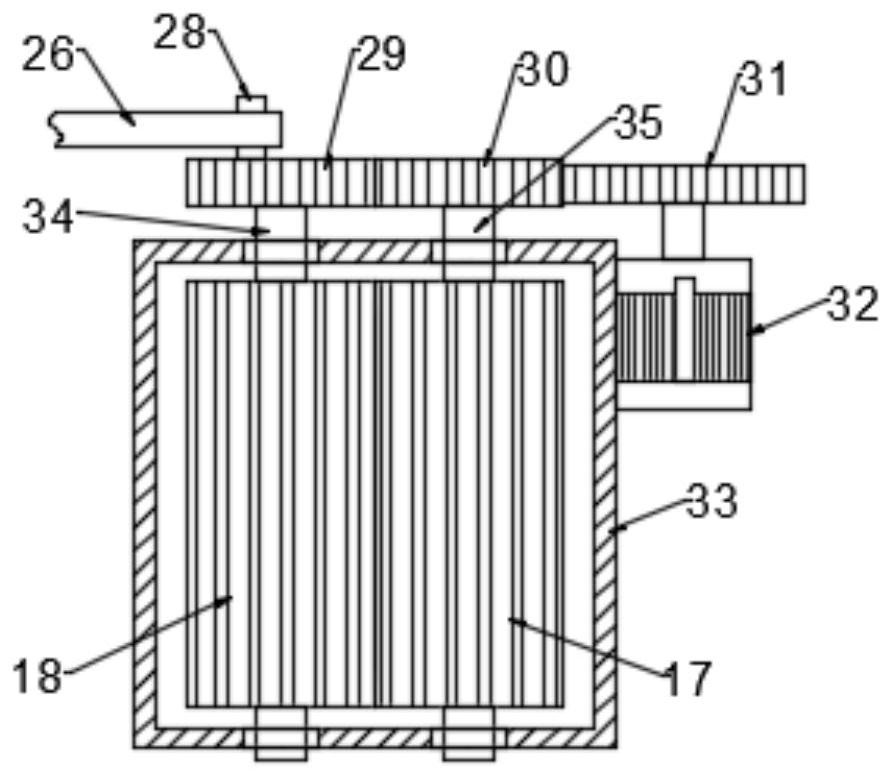

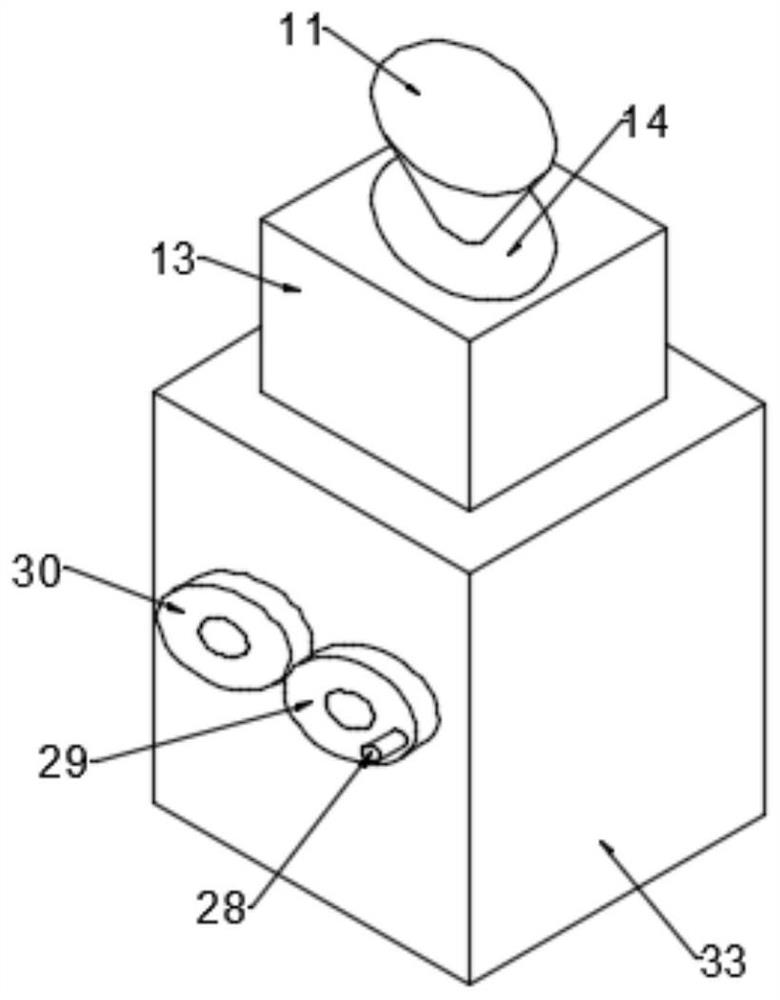

[0029] see Figure 1-3 , in an embodiment of the present invention, a multi-stage crushing device for construction processing includes a bottom plate 1, a vertical plate 2 is fixed on the bottom plate 1; a first support plate 3 and a second support plate 27 are installed on the vertical plate 2, The first support plate 3 is provided with a crushing box 33, the second support plate 27 is provided with a crushing seat 13, the crushing seat 13 is installed on the crushing box 33, and the crushing seat 13 is provided with a crushing groove 14, and the crushing box The top wall of 33 is provided with a discharge opening 15 communicating with the crushing tank 14, the bottom wall of the crushing box 33 is connected with a feeding pipe 20, the crushing seat 13 is provided with a beating assembly, and the crushing box 33 is provided with a crushing unit. crushing assembly; when in use, put the material to be crushed into the crushing tank 14 on the crushing seat 13, use the beating as...

Embodiment 2

[0041] see Figure 4 , in the embodiment of the present invention, a multistage pulverizing device for construction processing is different from embodiment 1 in that the bottom of the guide chute 23 is connected with a pillar 36, and the bottom end of the pillar 36 is connected with a bearing seat 37, and the bearing The seat 37 is installed on the bottom plate 1; through the cooperation of the pillar 36 and the bearing seat 37, the direction of rotation of the material guide groove 23 can be adjusted so as to adjust the blanking position to meet the requirements of different blanking positions and to be convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com