Recovery equipment for magnetic waste gas treatment

A kind of exhaust gas treatment equipment and exhaust gas treatment technology, which is applied in the directions of magnetic separation, solid separation, and dispersed particle separation, etc., can solve the problems of resource loss, iron impurities that cannot be recycled, and waste gas that cannot be recycled and utilized, so as to improve work efficiency, The effect of speeding up the waste gas treatment work and speeding up the adsorption work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

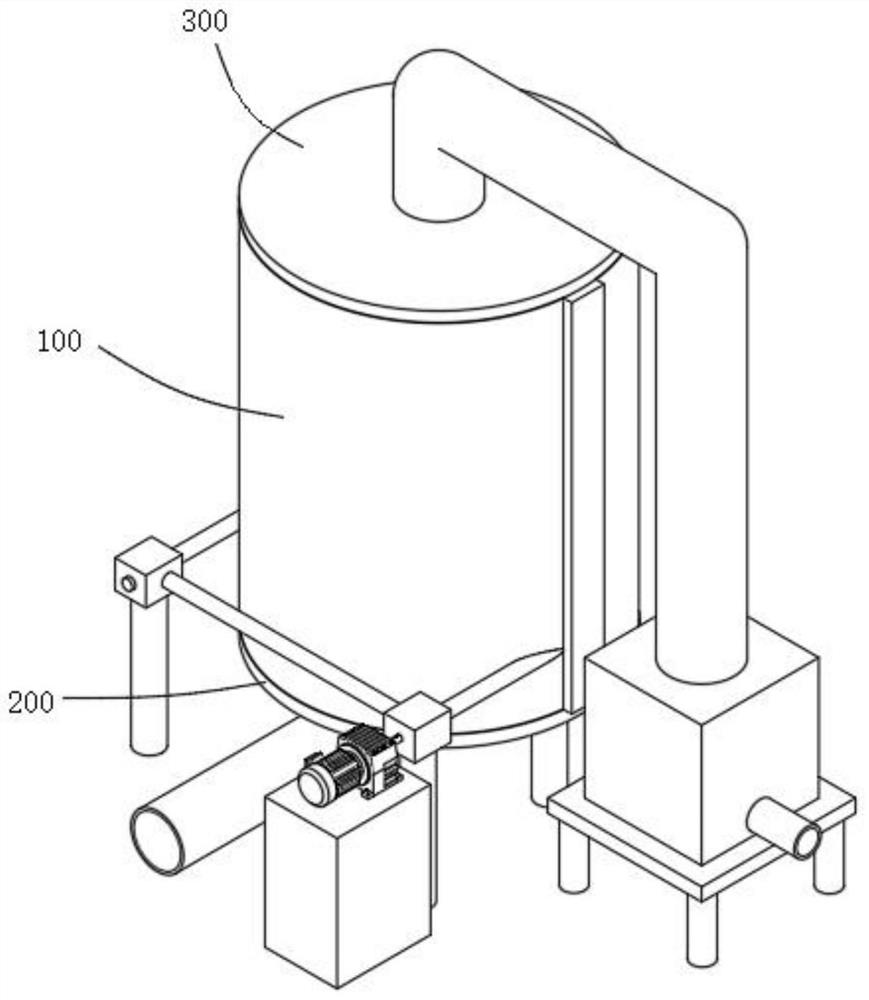

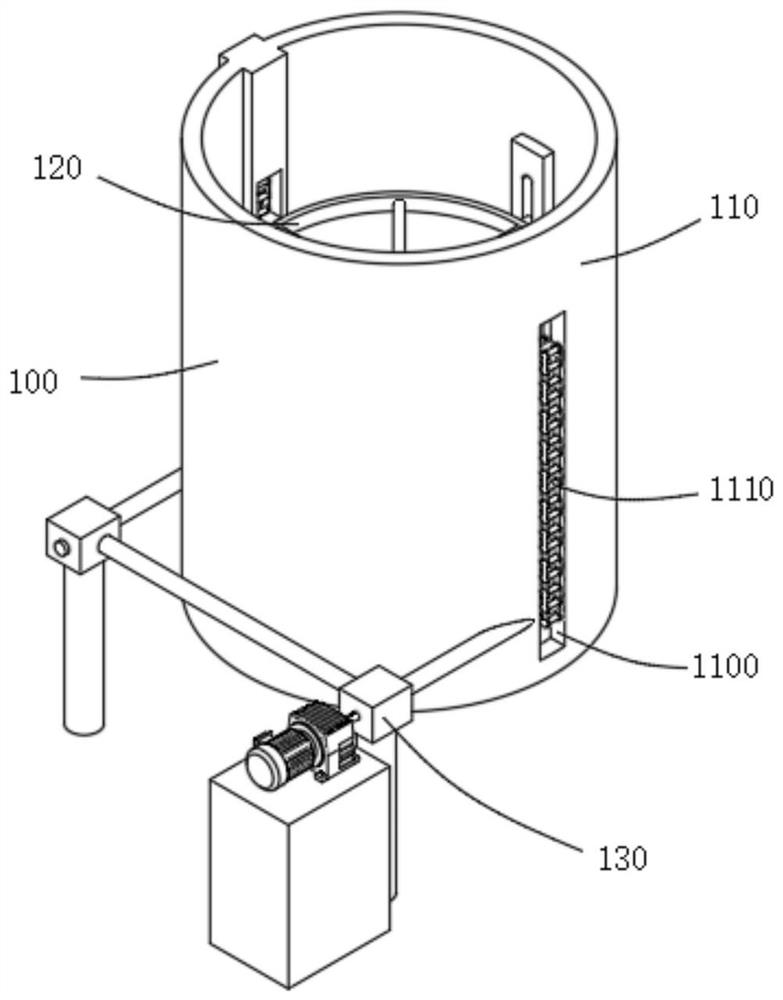

[0052] see Figure 1-Figure 13 As shown, this embodiment provides recovery equipment based on magnetic waste gas treatment, including waste gas treatment equipment 100 and a bottom plate 200 connected to the bottom of the waste gas treatment equipment 100, the top of the waste gas treatment equipment 100 is connected with a top cover 300, and the waste gas treatment equipment 100 includes at least :

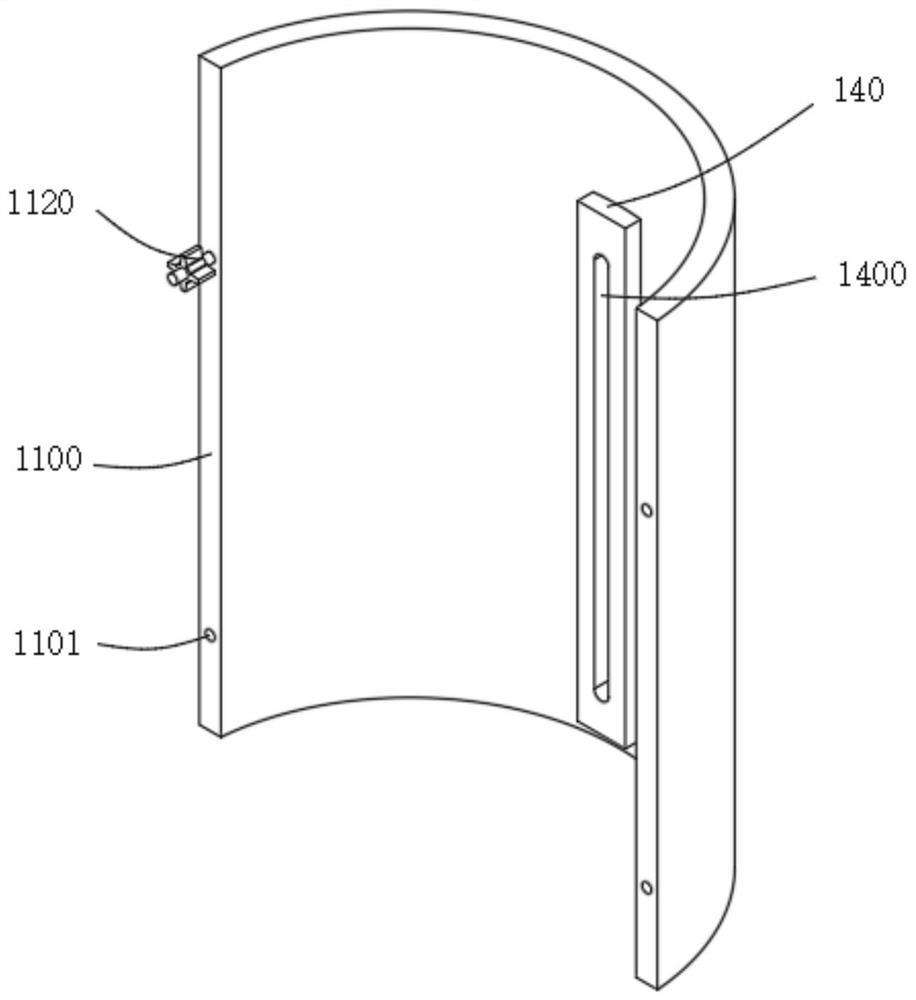

[0053] Disposal box 110, side slots 1100 are opened on both sides of the treatment box 110, chains 1110 are installed inside the side slots 1100, tooth blocks 1120 are connected to the upper and lower ends of the chain 1110, and rotation holes are provided on the upper and lower ends of the side slots 1100 1101, both ends of the tooth block 1120 are provided with rotating pins 1121, the rotating pins 1121 at both ends are respectively located inside the rotating hole 1101, and are connected in rotation with the rotating hole 1101, and the rotation between the rotating pin 1121 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com