Two-stage condensation and solution-dehumidification type white smoke eliminating device for low-temperature dust-containing smoke and working method

A solution dehumidification and flue gas technology, applied in chemical instruments and methods, separation methods, steam condensation, etc., can solve problems such as relative moisture content reduction, flue gas moisture content reduction, performance limitations, etc., to solve the problem of haze , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

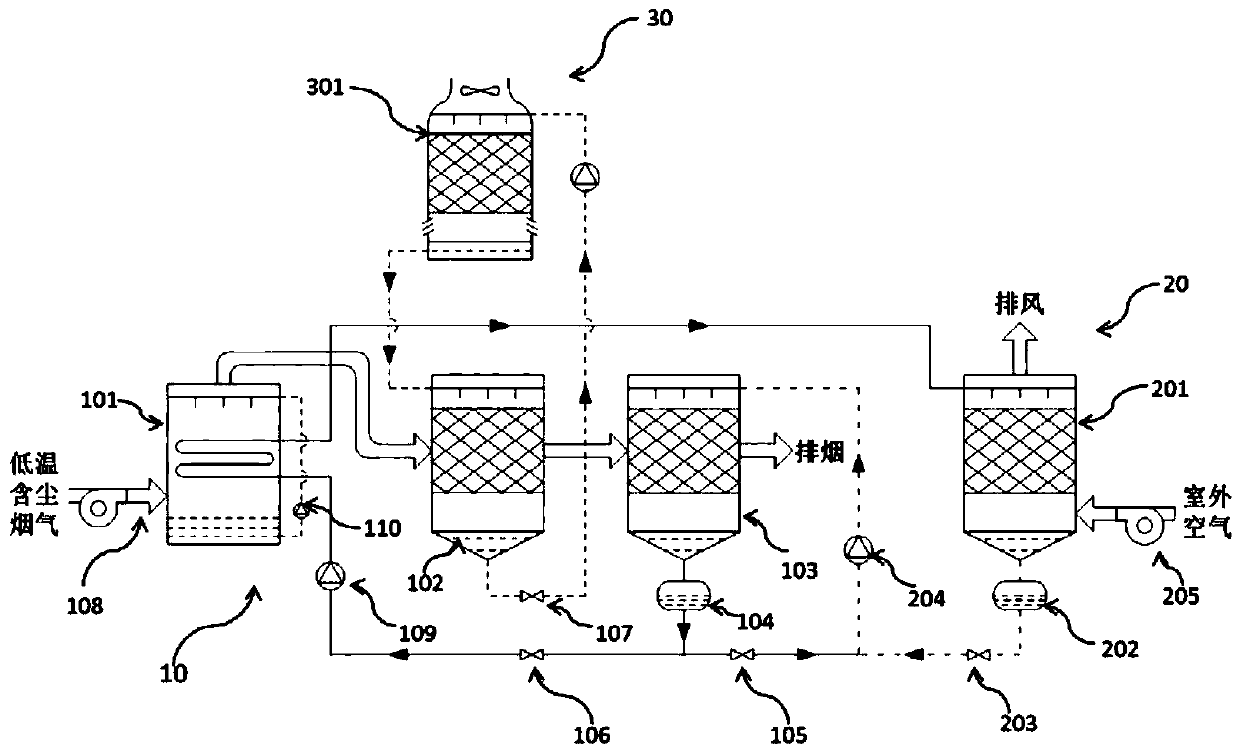

[0029] Such as figure 1 As shown, a low-temperature dust-containing flue gas white smoke elimination device with two-stage condensation and solution dehumidification according to the present invention includes a dehumidification and white smoke elimination system 10 , a waste heat recovery solution regeneration system 20 and a cooling water circulation system 30 .

[0030] The dehumidification and white smoke elimination system 10 includes a closed heat source tower 101 for heat exchange of low-temperature dusty flue gas, a spray tower 102 connected to the gas outlet of the closed heat source tower 101 and a dehumidifier connected to the gas outlet of the spray tower 102 103; heat exchange coils are arranged inside the closed heat source tower 101, and the circulating water pump 110 drives the spray water to self-circulate, and the spray water is sent to the shower installed above the closed heat source tower 101, and the closed heat source tower 101 side The wall is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com