Cooling and dedusting device for industrial machinery manufacturing

A dust removal device and industrial machinery technology, which is applied in household refrigeration devices, applications, household appliances, etc., can solve problems such as damage to mobile devices, achieve the effects of increased service life, simple structure, and improved cooling and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

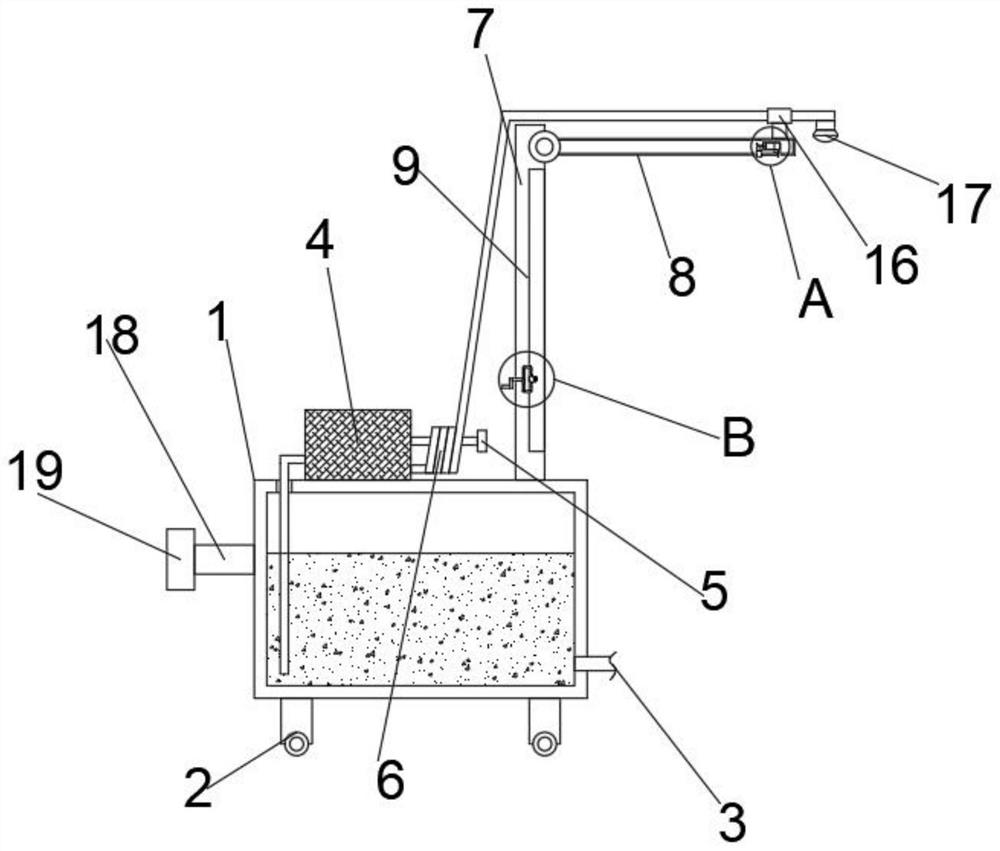

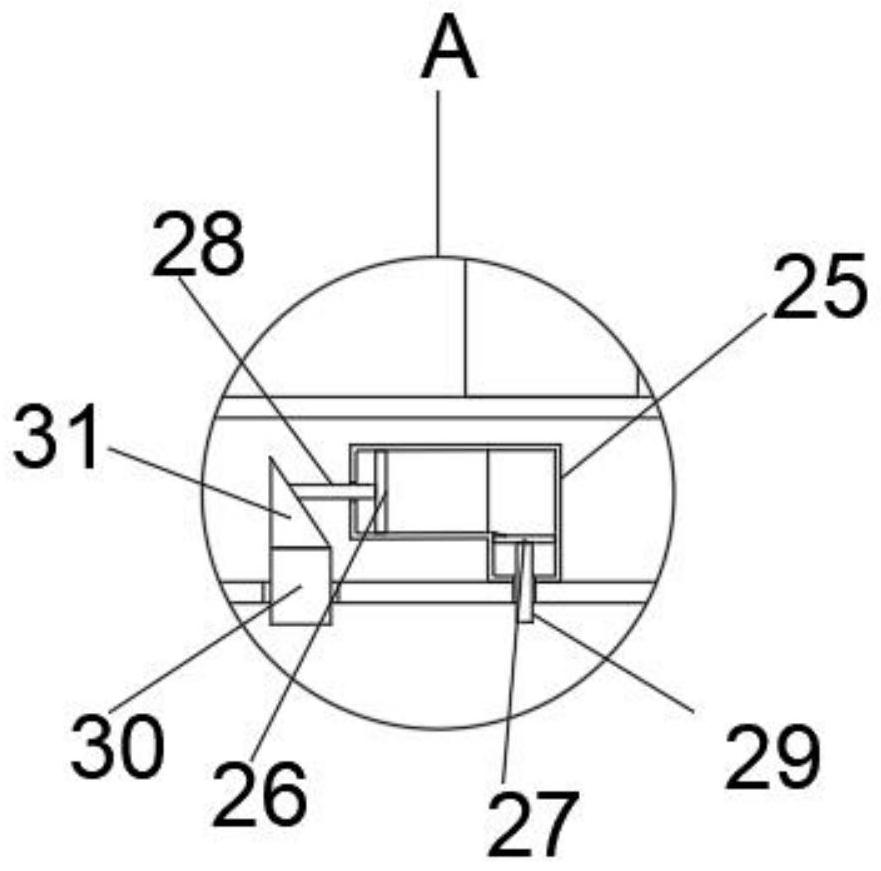

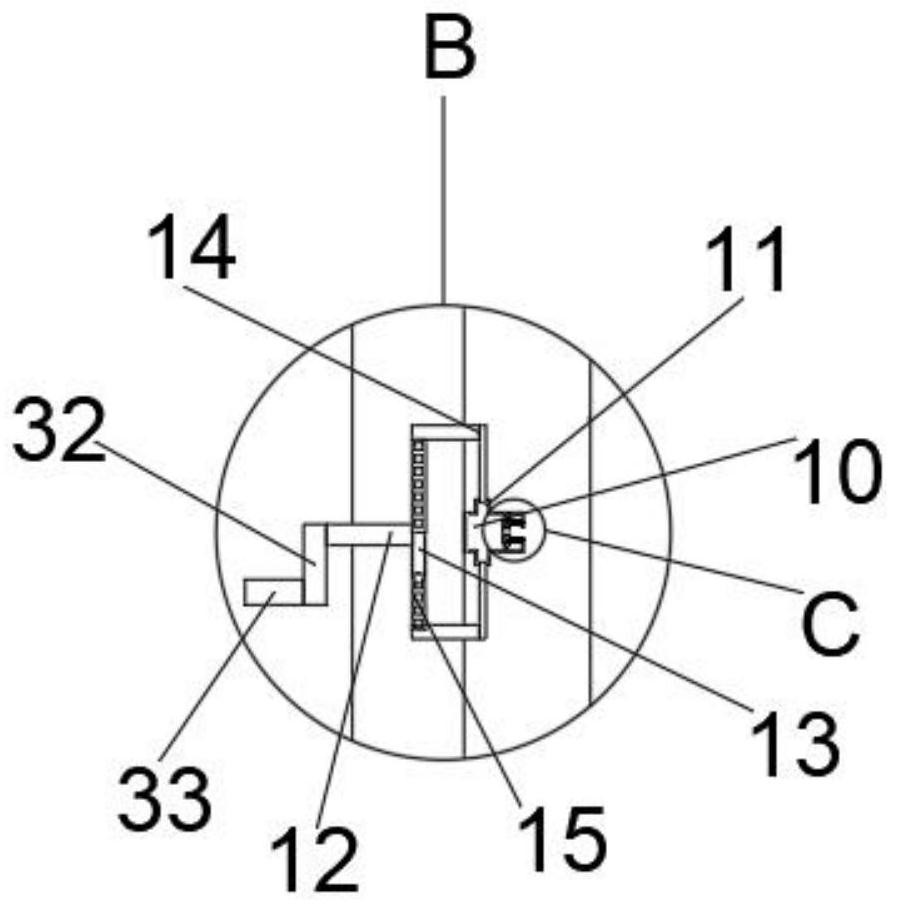

[0022] refer to Figure 1-5 , a cooling and dust removal device for industrial machinery manufacturing, comprising a water tank 1, the side wall of the water tank 1 is fixedly connected with a plurality of universal wheels 2, the side wall of the water tank 1 is provided with a pushing mechanism, and the side wall of the water tank 1 is sealed and connected with a water inlet pipe 3. The side wall of the water tank 1 is fixedly connected with the water pump 4, the water inlet pipe 3 of the water pump 4 is sealedly connected with the side wall of the water tank 1, the side wall of the water pump 4 is fixedly connected with the placing rod 5, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap