Disinfection machine of fiberscope for gastroenterology department

A fiberscope, gastrointestinal technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of complicated operation and incomplete disinfection, and achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

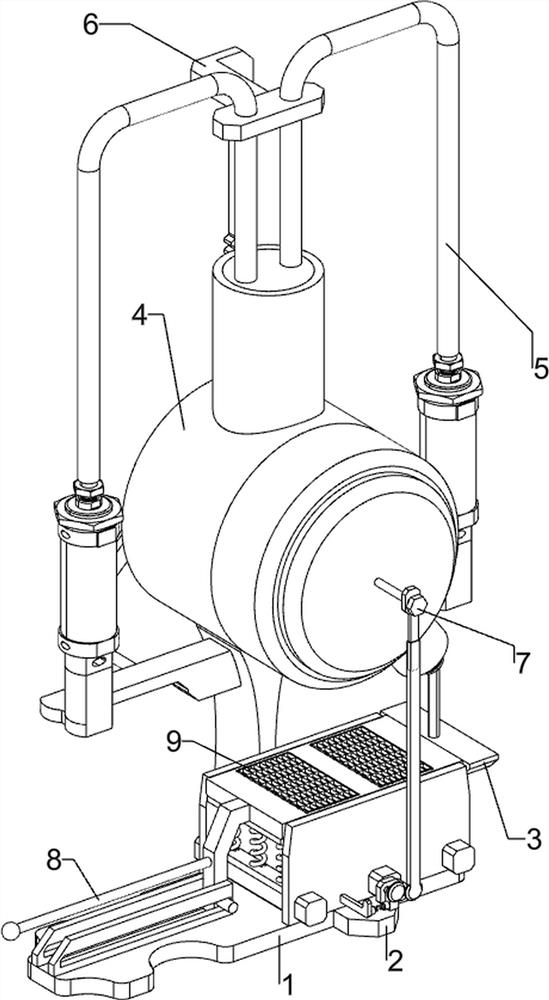

[0070] A fiberscope disinfection machine for gastroenterology, such as figure 1 As shown, it includes a base plate 1, a bearing plate 2, a placement assembly 3 and a spraying mechanism 4. The front side of the base plate 1 is connected with the load bearing plate 2, the upper side of the base plate 1 is connected with the placement assembly 3, and the upper side of the base plate 1 is connected with the spraying mechanism 4.

[0071] When the device needs to be used, the user can place the fiberscope on the placement component 3 to achieve the purpose of placing the fiberscope and facilitate subsequent operations, pour clean water into the spray mechanism 4, and the clean water is sprayed through the spray mechanism 4 To place on the component 3, clean the fiberscope, so as to achieve the purpose of cleaning the fiberscope for subsequent use, and repeat the operation when it is used again.

Embodiment 2

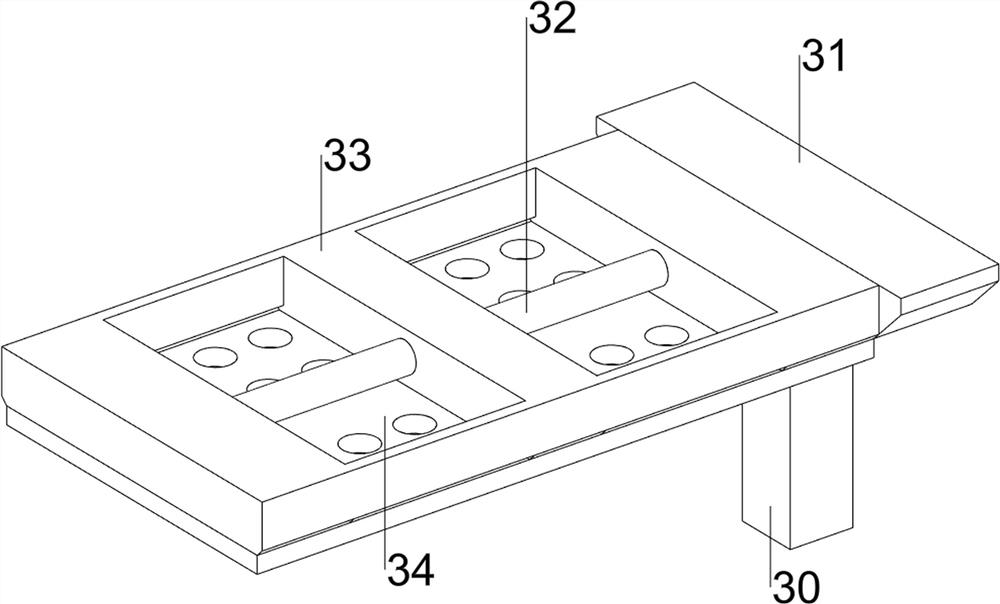

[0073] On the basis of Example 1, such as figure 2 As shown, the placement assembly 3 includes a leg 30, a first fixing plate 31, a support column 32, a first mounting plate 33 and a second mounting plate 34, the upper side of the bottom plate 1 is connected with the leg 30, and the upper side of the leg 30 is connected with the first The fixing plate 31, the second mounting plate 34 is connected to the lower side of the first fixing plate 31, the first mounting plate 33 is arranged on the upper side of the second mounting plate 34, and the supporting column 32 is connected between the left and right inner walls of the first mounting plate 33 , the support column 32 passes through the first mounting plate 33 .

[0074] When the device needs to be used, the user can place the fiberscope on the upper side of the second mounting plate 34, the fiberscope is located in the first mounting plate 33, and the fiberscope is in contact with the support column 32 to achieve the placement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com