Plate correcting system

A correction system and plate technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of high number of times of piston rod expansion and contraction, slow frequency of cylinder expansion and expansion, poor correction effect, etc., and achieve good pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

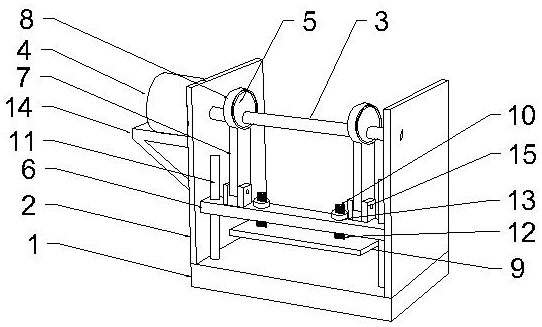

[0010] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , a plate correction system described in this embodiment includes a base 1, side plates 2 are vertically fixed on the top of both sides of the base 1, and a rotating shaft 3 is movably installed between the upper parts of the two side plates 2, and one of the side plates 2 A rotating motor 4 is installed on the outer wall, and a motor mount 14 is fixed on the outer wall of one of the side plates 2 , and the rotating motor 4 is installed on the top of the motor mount 14 . The transmission shaft of the rotating motor 4 passes through the side plate 2 and is connected to the rotating shaft 3. An eccentric wheel 5 is fixedly installed on the rotating shaft 3. A lifting plate 6 is arranged below the rotating shaft 3. A lifting arm 7 is hinged on the top of the lifting plate 6. The lifting plate 6. A h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap