Herringbone gear centering degree on-line measurement and correction method

A herringbone gear and centering technology, which is applied in the direction of measuring/indicating equipment, gear tooth manufacturing devices, belts/chains/gears, etc., can solve the problem that the medium error of the herringbone gear is difficult to guarantee, the assembly process is time-consuming, and affects the grinding of teeth Processing accuracy and other issues to achieve the effect of improving processing accuracy, avoiding measurement errors, and facilitating motion correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

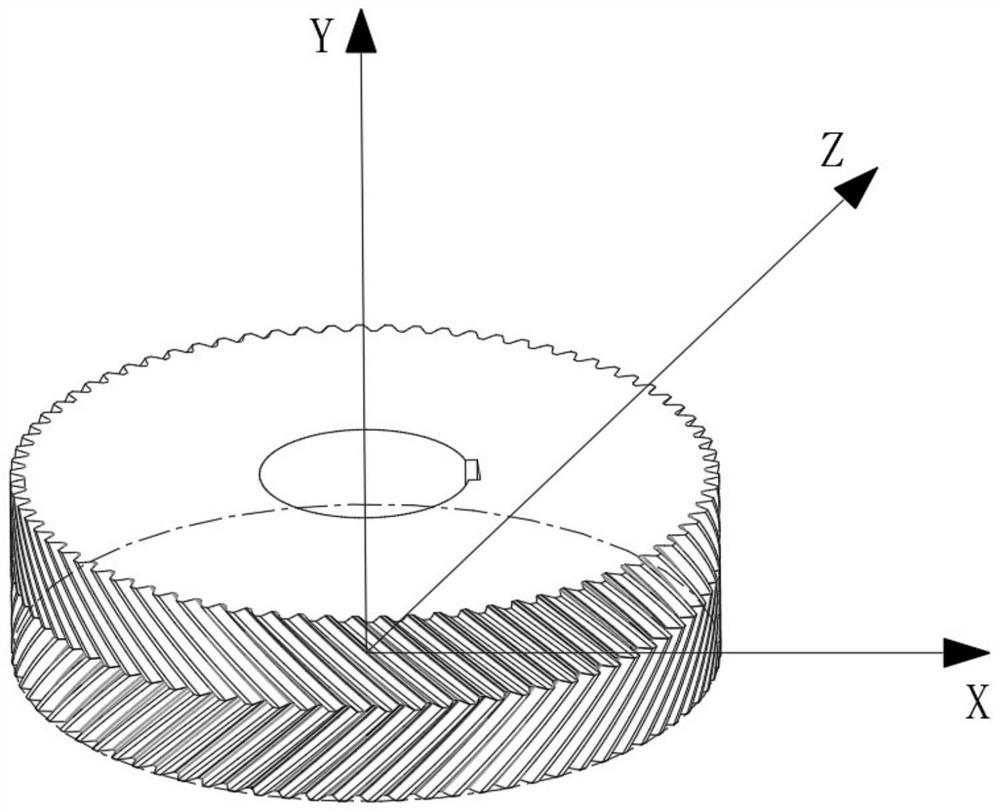

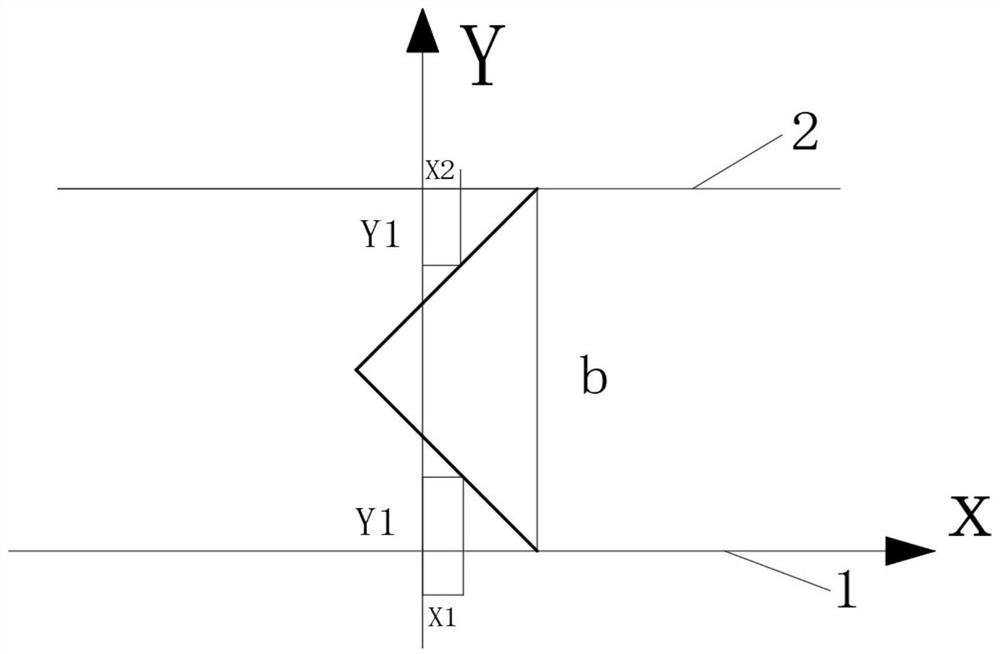

[0020] The following will combine Figure 1 to Figure 3 To illustrate this embodiment, the specific steps of a method for online measurement and correction of a herringbone gear alignment moderate error described in this embodiment are as follows:

[0021] Herringbone gear related parameters, such as figure 1 Shown: gear module: 12, number of teeth: 78, tooth pressure angle 20°, tooth helix angle 14°.

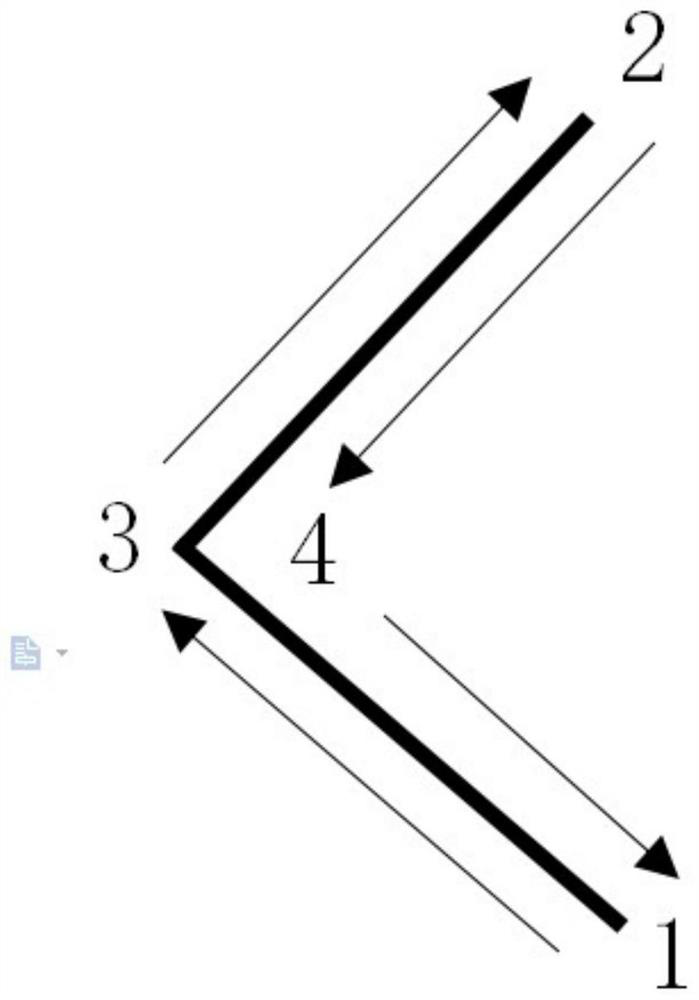

[0022] Step 1. Determination of the tool path, such as figure 2 Shown: After the tool setting is completed, the Z-axis and C-axis linkage tool of the machine tool moves in a spiral motion relative to the workpiece, moving from the lower end surface to the middle position, that is, from position 1 to position 3, and then from the middle position to the upper end surface, that is, from the From position 3 to position 2, the machining of the left tooth surface is completed. The tool moves to the next cutting position, and the Z-axis and C-axis linkage tool performs a spiral mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com