Preparation method of large wall thickness stainless steel/carbon steel layered structure composite pipe

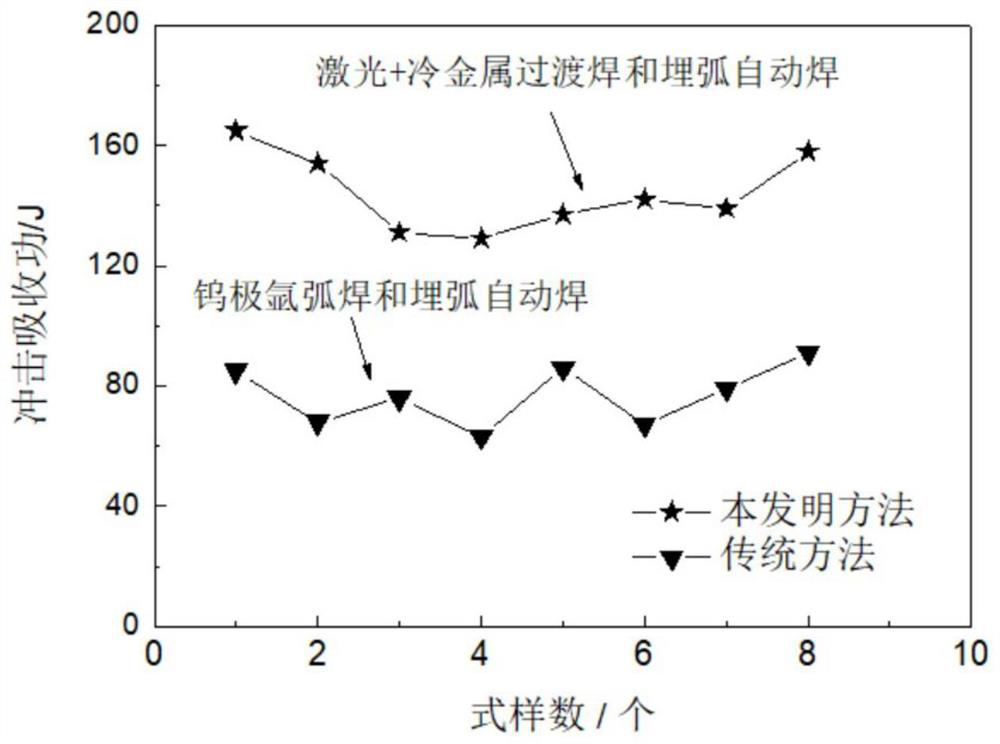

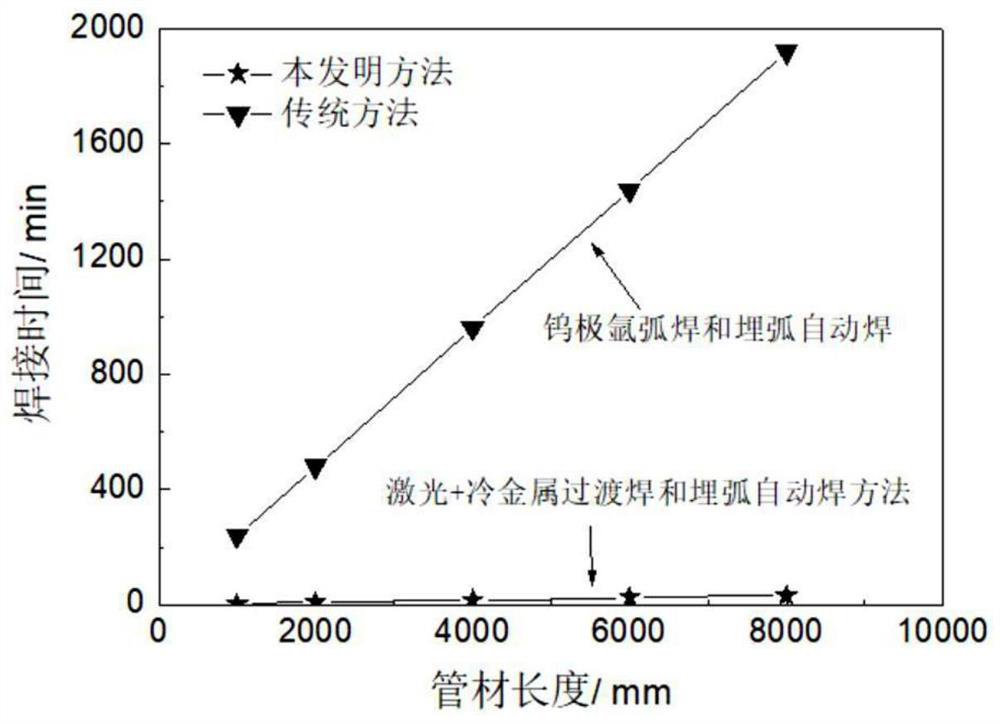

A stainless steel layer, composite pipe technology, applied in manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of low welding efficiency, poor weld quality and performance, and achieve improved weld quality and performance, and production efficiency. Increased, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

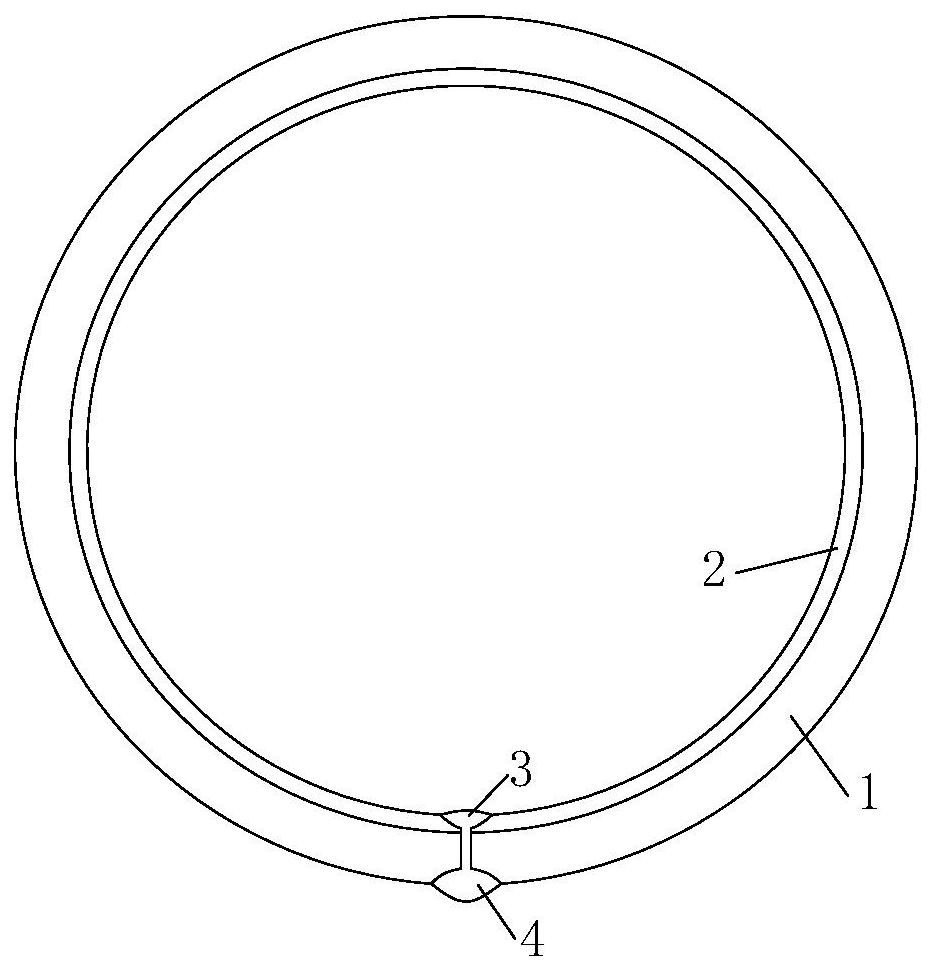

[0033] see figure 1 , the 2205 / X65 large wall thickness stainless steel / pipeline steel layered structure composite plate with a wall thickness of 28mm prepared by "vacuum sealing welding + hot rolling + continuous controlled rolling and controlled cooling" is used as the experimental raw material plate, and the thickness of the 2205 stainless steel layer is 3mm The thickness of the X65 pipeline steel layer is 25mm. After cleaning the debris, rust and hard blocks on both sides of the plate, the Φ610×28mm 2205 / X65 stainless steel / pipeline steel layered structure composite pipe is manufactured. The specific steps are as follows:

[0034] Step 1: Carry out "I+V" groove milling on two longitudinal sides of the 2205 / X65 large-wall stainless steel / pipeline steel layered structure composite plate, and clean the surface again within the range of 10-20mm on both sides of the groove. The specific parameters of the groove processing are: "V" type groove is located on the side of the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com