Metal flange plate machining equipment for pipe fitting connection

A processing equipment and metal technology, which is applied in the field of metal flange processing equipment for pipe fittings, can solve the problems of difficult grinding and slow efficiency, and achieve the effect of facilitating drilling and chamfering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

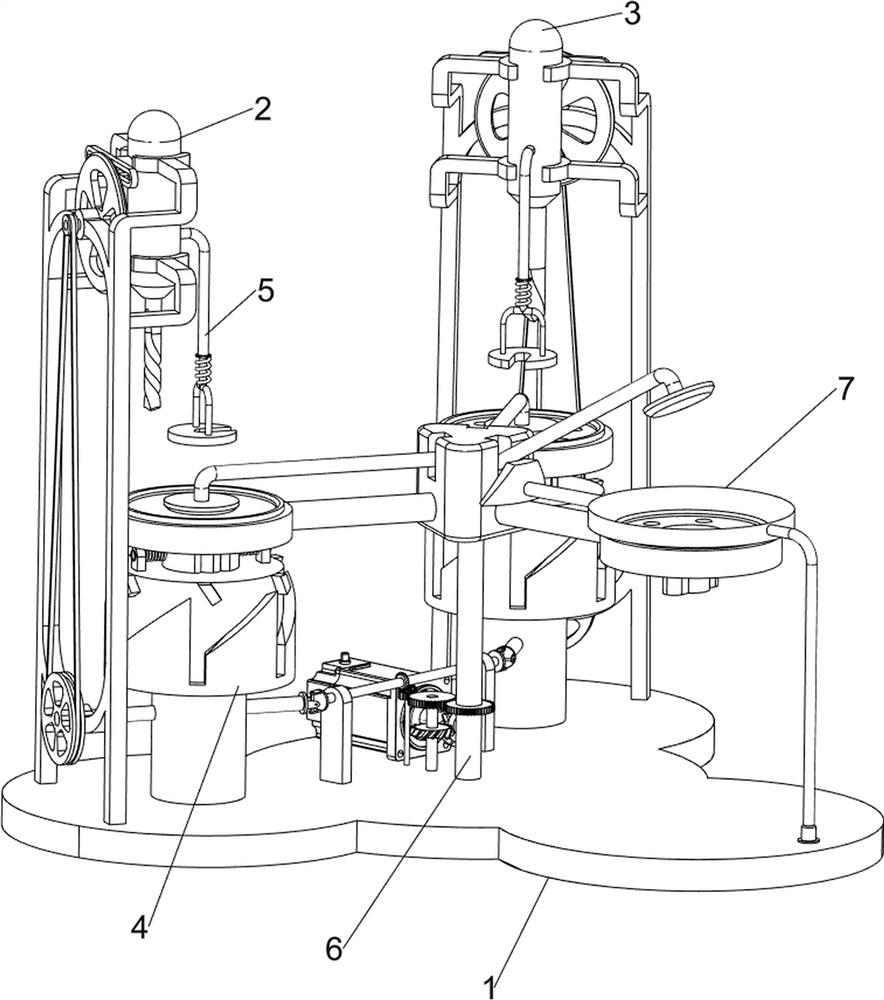

[0064] A metal flange processing equipment for pipe fittings, such as figure 1 As shown, a base plate 1, a punching mechanism 2 and a chamfering mechanism 3 are included, the punching mechanism 2 is provided on the top left side of the base plate 1, and the chamfering mechanism 3 is provided on the top right side of the base plate 1.

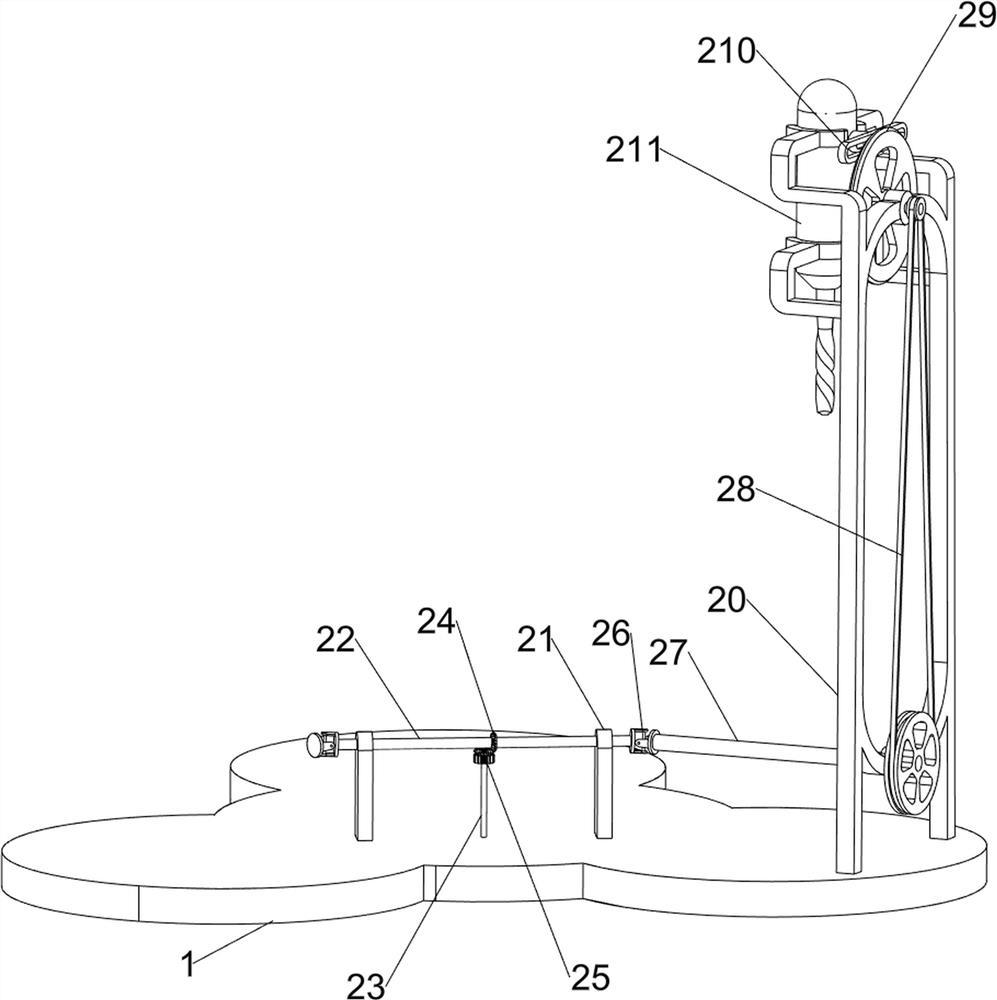

[0065] Such as figure 2As shown, the punching mechanism 2 includes a first support frame 20, a bearing seat 21, a first rotating shaft 22, a second rotating shaft 23, a bevel gear 24, a first gear 25, a universal joint 26, a third rotating shaft 27, a first Pulley group 28, first turntable 29, first slide rail 210 and puncher 211, base plate 1 top left side is provided with first support frame 20, and base plate 1 top center left and right symmetrically is provided with bearing seat 21, between bearing seat 21 Connected with the first rotating shaft 22, the bottom plate 1 is provided with a second rotating shaft 23 in the middle of the rotatio...

Embodiment 2

[0069] On the basis of Example 1, such as Figure 4 As shown, a rotating mechanism 4 is also included, and the rotating mechanism 4 includes a mounting column 40, a sheave 41, a push rod 42, a limit rod 43, a first spring member 44 and a clip 45, and the left and right sides of the top of the base plate 1 are provided with Mounting post 40 is arranged, and the third rotating shaft 27 and the fourth rotating shaft 31 are all rotatably matched with the mounting post 40, and the mounting post 40 is provided with a sheave 41 in a rotating manner, and the puncher 211 and the chamfering device 35 are provided with pushers. Rod 42, push rod 42 cooperates with sheave 41, and the left and right sides of sheave 41 top all slides and is provided with limit bar 43, and the inside of limit bar 43 is all provided with clip block 45, between clip block 45 and sheave 41 A first spring element 44 is attached.

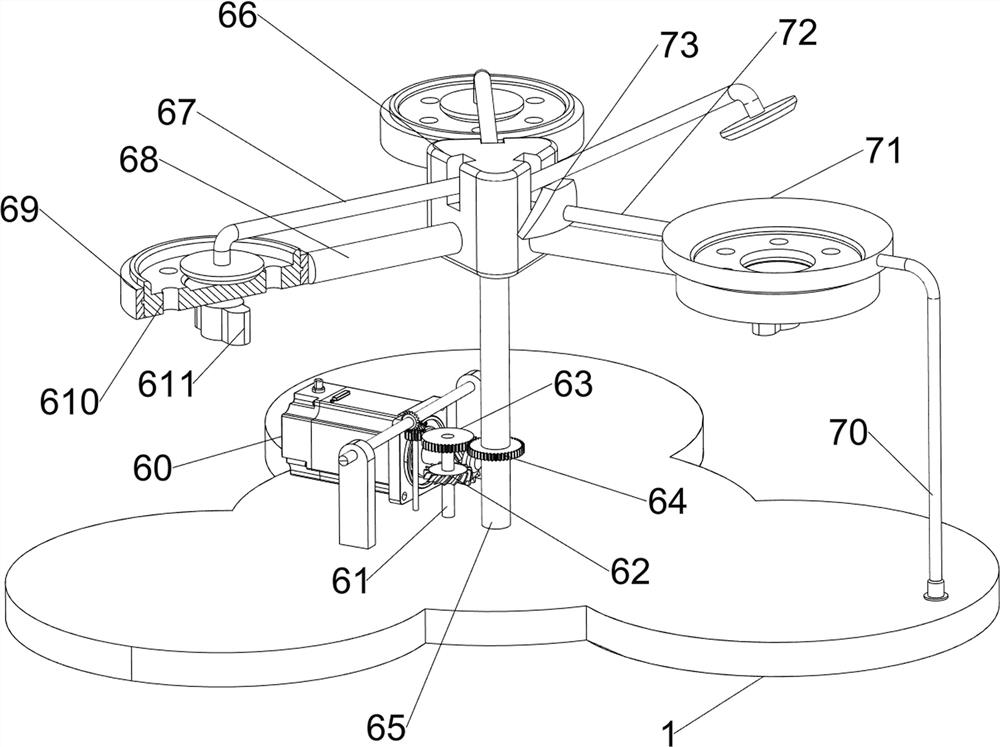

[0070] Such as Figure 5 Shown, also comprise rotating mechanism 6, and rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com