Detonator reverse mold manipulator

A technology of manipulators and robotic arms, which is applied in the field of detonator inversion manipulators, can solve problems such as the inability to realize automatic inversion, and achieve the effects of improving operational safety, avoiding direct contact, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

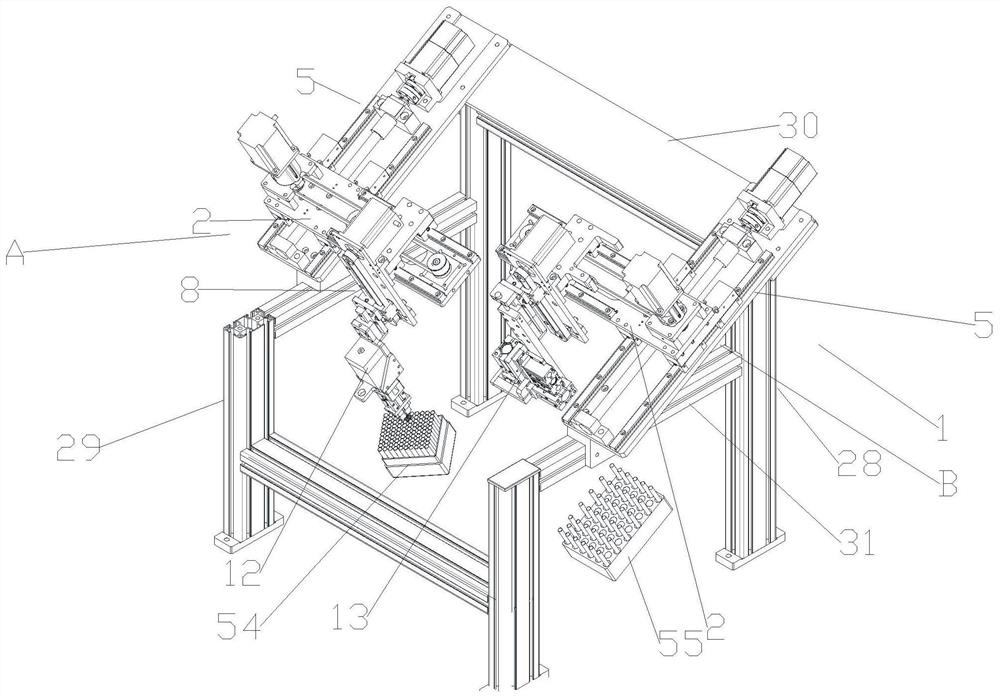

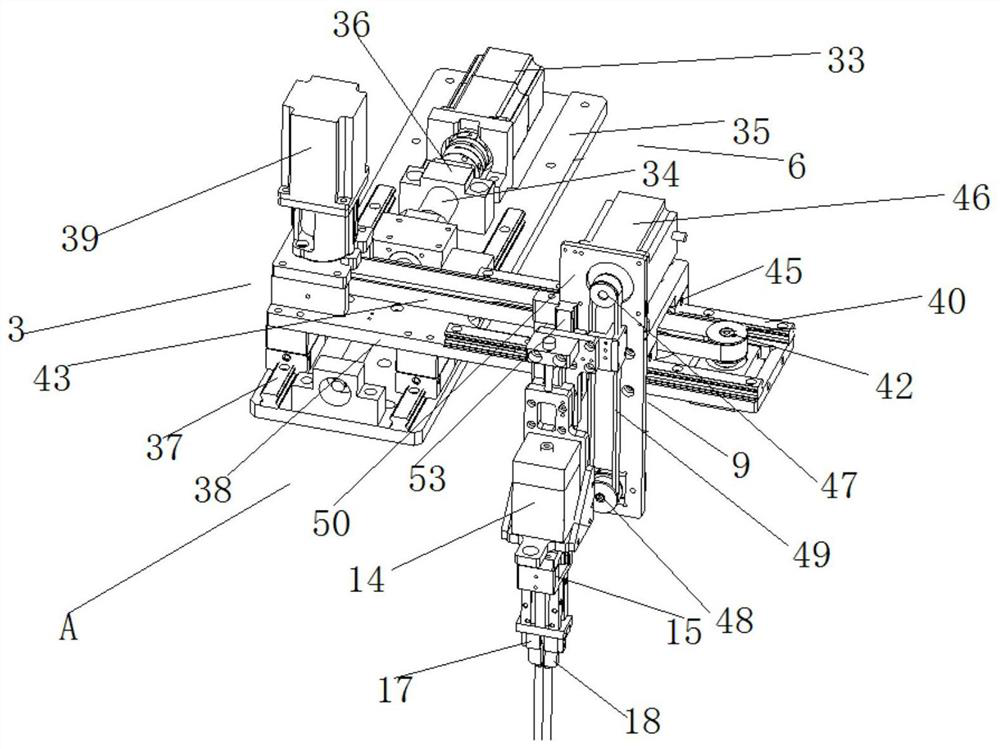

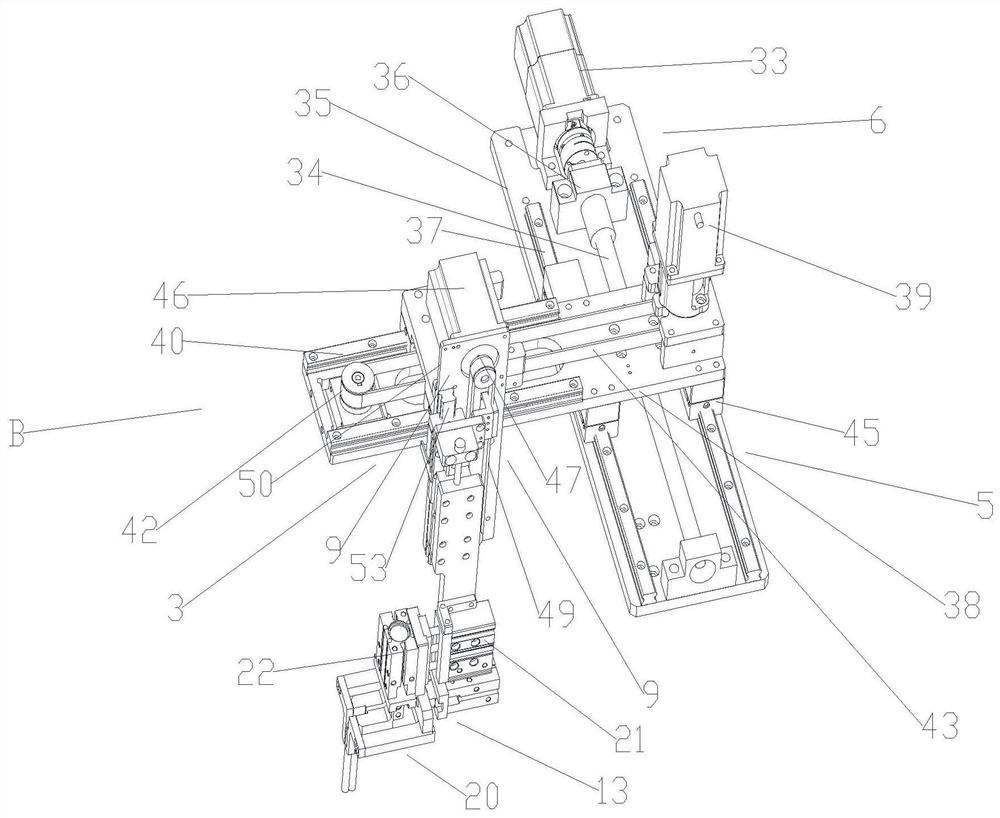

[0033] combined with Figure 1-9 , the present embodiment provides a detonator inversion manipulator, including: a frame 1; 2 includes an X-axis drive assembly 3, the X-axis drive assembly 3 is provided with an X-axis slider connecting plate 4; a Y-axis assembly 5, the X-axis assembly 2 is arranged on the Y-axis assembly 5, and the Y-axis assembly 5 is arranged on the frame 1, the Y-axis assembly 5 includes a Y-axis drive assembly 6, and the Y-axis drive assembly 6 is provided with a Y-axis slider connecting plate 7, and the Y-axis slider connecting plate 7 Fixedly connected with the X-axis assembly 2; Z-axis assembly 8, the Z-axis assembly 8 is arranged on the X-axis assembly 2, the Z-axis assembly 8 includes a Z-axis drive assembly 9, on the Z-axis drive assembly 9 A Z-axis slider connecting plate 51 is provided, and the X-axis slider connecting plate 4 is fixedly connected with the Z-axis assembly 8; a claw assembly, the claw assembly is arranged on the Z-axis assembly 8, ...

Embodiment 2

[0036] combined with Figure 1-3 , the detonator inversion manipulator of this embodiment, compared with the technical solution of embodiment 1, if the claw assembly is the R-axis rotating claw 12, the R-axis rotating claw 12 is fixed to the Z-axis slider connecting plate 51 Connection; if the claw assembly is the pipe release claw 13, the pipe release claw 13 is fixedly connected with the Z-axis slider connecting plate 51. The R-axis rotating claw 12 is used to clamp the detonator from the turnover box 54, and the pipe-putting claw 13 is used to place the detonator at the specified position in the combined mold 55.

[0037] When it is necessary to get the detonator stored in the turnover box 54, according to the position of the detonator to be taken, the X-axis slider connecting plate 4 in the X-axis assembly 2 in the mechanical arm, and the Y-axis slider connecting plate in the Y-axis assembly 5 7. The Z-axis slider connection plate 51 in the Z-axis assembly 8 moves synchro...

Embodiment 3

[0041] combined with Figure 1-3 , the detonator inversion manipulator of the present embodiment, compared with the technical solution of embodiment 1, described manipulator has two, two manipulators are arranged on the described frame 1 oppositely, wherein the claw assembly of one manipulator is The R-axis rotates the claw 12, and the claw assembly of another mechanical arm is the pipe claw 13.

[0042] In this embodiment, two mechanical arms are relatively arranged on the frame 1, and the claw assembly of one mechanical arm is an R-axis rotating claw 12. This mechanical arm is called the first mechanical arm A, and the first mechanical arm A Used to clamp and store the detonators stored in the turnover box 54; the claw assembly of another mechanical arm is the pipe claw 13, and this mechanical arm is called the second mechanical arm B, and the second mechanical arm B is used to place the detonator in the combination module 55; specifically, when it is necessary to take the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com