Electronic part automatic machining equipment

A technology of electronic parts and processing equipment, which is applied in the field of automatic processing equipment for electronic parts, can solve the problems of inability to meet the mass production of parts, low production efficiency, and high labor intensity, and achieve automatic processing, low cost, and labor low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

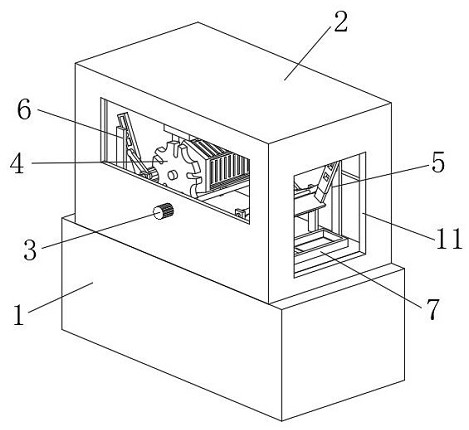

[0036] An electronic component automatic processing equipment, such as Figure 1-2 As shown, including the console 1, the upper end of the console 1 is fixedly equipped with a protective cover 2, and the front and rear sides of the middle part of the upper end of the console 1 are fixedly welded with support plates 21, and the two support plates 21 are located in the protective cover 2. The middle part of the rear end of the cover 2 is interspersed with a drive mechanism 3, and the drive mechanism 3 is movably connected with the support plate 21 through a bearing, and a positioning mechanism 4 is movably connected between the two support plates 21, and the positioning mechanism 4 is located above the drive mechanism 3 and It is connected with the drive mechanism 3 through transmission, and the left and right sides of the upper end of the console 1 are fixedly installed with a discharging mechanism 6 and a retrieving mechanism 5 respectively, and both the retrieving mechanism 5 an...

Embodiment 2

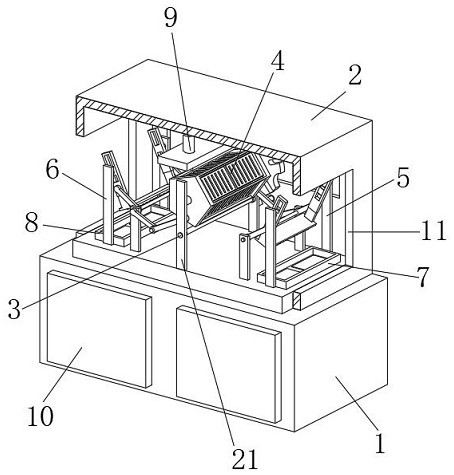

[0039] On the basis of Example 1, as Figure 6-8 As shown, an automatic processing equipment for electronic components includes an operation table 1, a protective cover 2 is fixedly installed on the upper end of the operation table 1, and support plates 21 are fixedly welded on the front and rear sides of the upper middle of the operation table 1, and the two support plates 21 are all located in the protective cover 2, the middle part of the rear end of the protective cover 2 is interspersed with a driving mechanism 3, and the driving mechanism 3 is movably connected with the support plate 21 through the bearing, and a positioning mechanism 4 is movably connected between the two support plates 21 to position The mechanism 4 is located above the driving mechanism 3 and is connected with the driving mechanism 3. The left and right sides of the upper end of the console 1 are respectively fixedly equipped with a discharging mechanism 6 and a retrieving mechanism 5, and the retrievi...

Embodiment 3

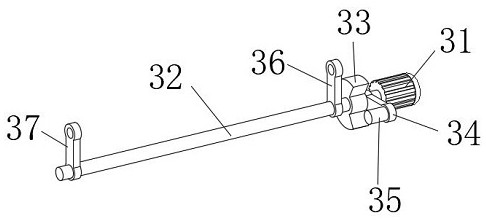

[0042] On the basis of Example 1, as Figure 3-5 As shown, an automatic processing equipment for electronic components includes an operation table 1, a protective cover 2 is fixedly installed on the upper end of the operation table 1, and support plates 21 are fixedly welded on the front and rear sides of the upper middle of the operation table 1, and the two support plates 21 are all located in the protective cover 2, the middle part of the rear end of the protective cover 2 is interspersed with a driving mechanism 3, and the driving mechanism 3 is movably connected with the support plate 21 through the bearing, and a positioning mechanism 4 is movably connected between the two support plates 21 to position The mechanism 4 is located above the driving mechanism 3 and is connected with the driving mechanism 3. The left and right sides of the upper end of the console 1 are respectively fixedly equipped with a discharging mechanism 6 and a retrieving mechanism 5, and the retrievi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com