Vacuum-driven actuator based on scissor mechanism

A scissors mechanism and actuator technology, applied in the field of vacuum drive actuators, can solve problems such as poor adaptability to the working environment, and achieve the effects of strong adaptability, reduced overall volume, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

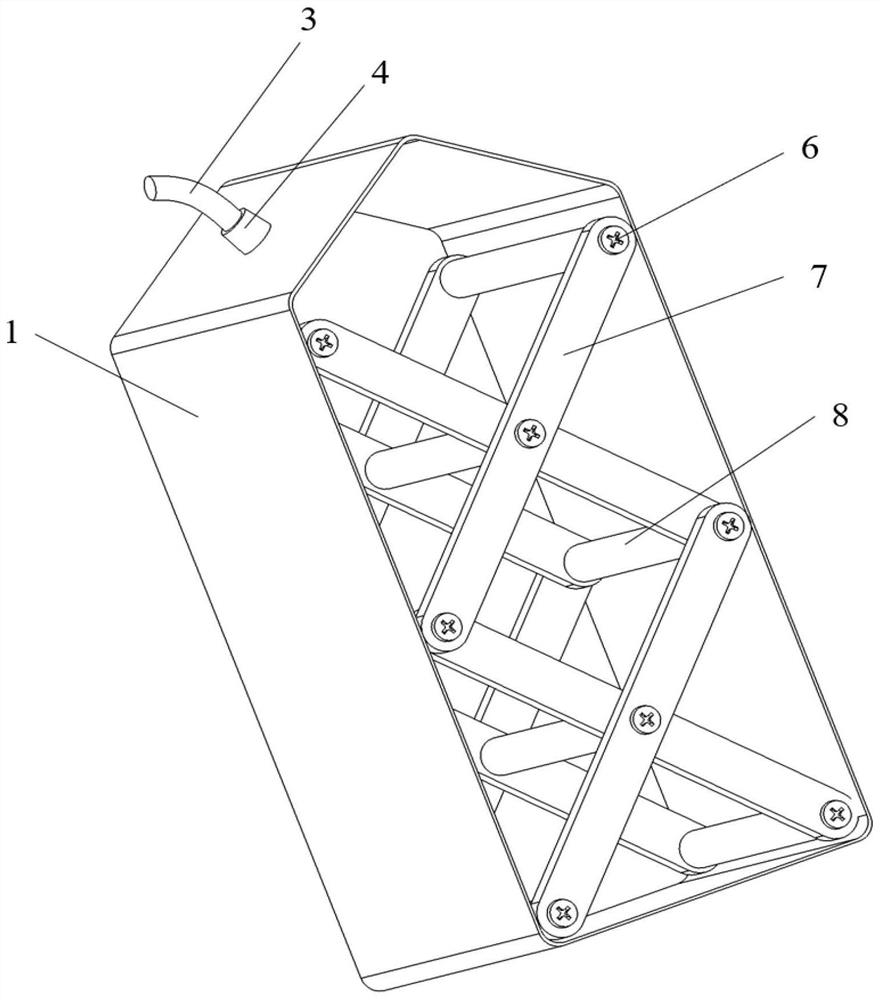

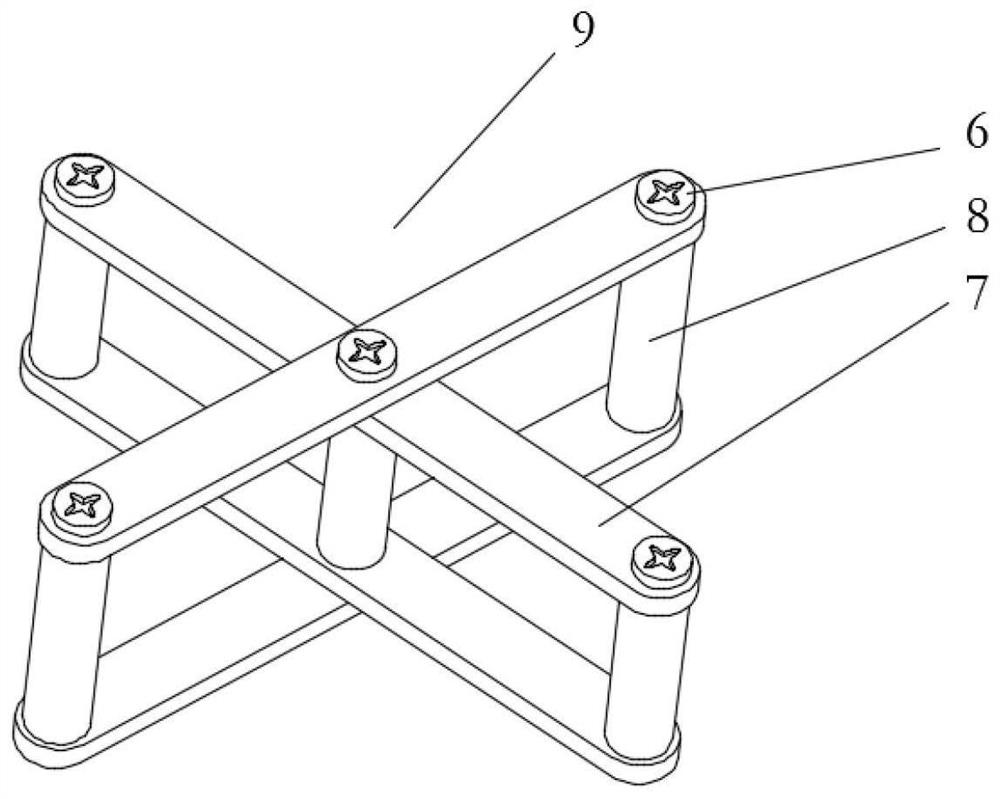

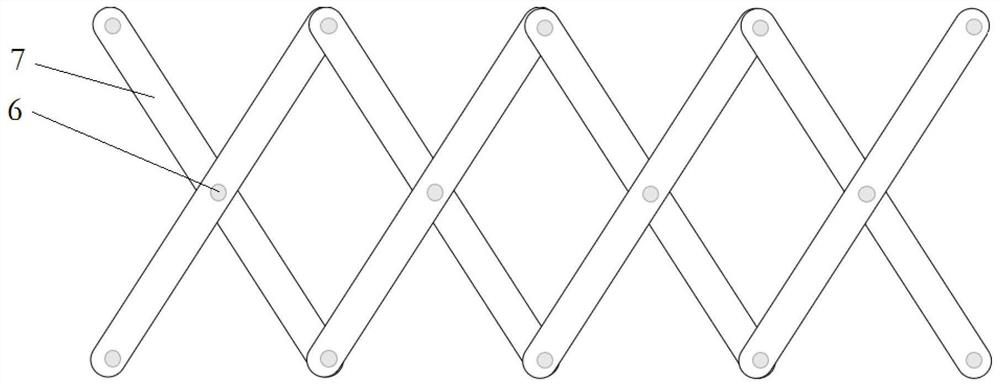

[0025] refer to Figure 1-4 As shown, a vacuum-driven actuator based on the scissors mechanism in the first embodiment, wherein the outer film 1 covers the outside of the entire scissors mechanism skeleton 2, and the outer film 1 is fixedly connected to the scissors mechanism skeleton 2, and the outer film 1 1 is provided with a pneumatic joint. When negative pressure is applied to the actuator, the outer film 1 will first shrink and push the scissors mechanism frame 2 to perform the overall contraction movement. During this process, the outer film 1 will always be close to the scissors mechanism frame 2, and there will be no outer film 1 and the scissor mechanism skeleton 2 are separated from each other. When the actuator is to return to its original position, it is necessary to inflate the interior of the actuator. At this time, if there is no restraint between the outer film 1 and the scissors mechanism skeleton 2, the two will separate and the actuator will fail. Therefo...

Embodiment 2

[0032] refer to Figure 5 As shown, the difference between the second embodiment and the first example is that the scissors mechanism framework 2 can also be made by intersecting the polygonal folded plates 5, so that the scissors mechanism framework 2 forms a thin-walled scissors mechanism framework. The scissors mechanism skeleton 2 of the present embodiment is made up of two polygonal folded plates 5, and each polygonal folded plate 5 is made by bending a plurality of parts of a rectangular sheet, and the thin sheet material is selected the material with good toughness, as paper, PVC plastic sheet Wait. Cut the openings that can cooperate with each other at the junction of the two polygonal flaps 5 respectively, and cross-plug the two parts to form the scissors mechanism skeleton 2, and glue the corners of the polygonal flaps 5 and the outer film 1 firmly. The working principle of the second embodiment is the same as that of the first embodiment, but it can only be used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com