Automatic tray implanting device

A technology for implanting devices and trays, which is applied in stacking receiving devices, transportation and packaging, thin material handling, etc., and can solve problems such as manual implanting of trays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Further description will be given below in conjunction with the embodiments of the accompanying drawings.

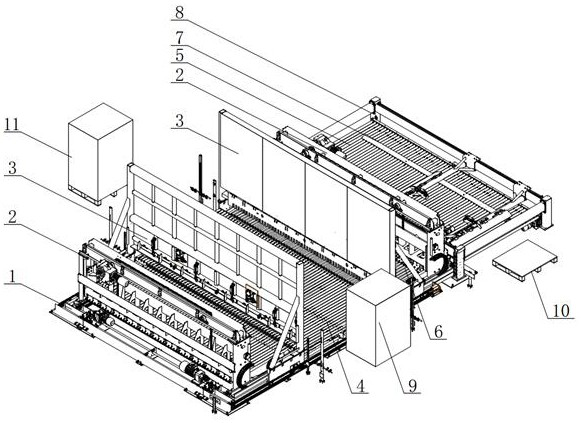

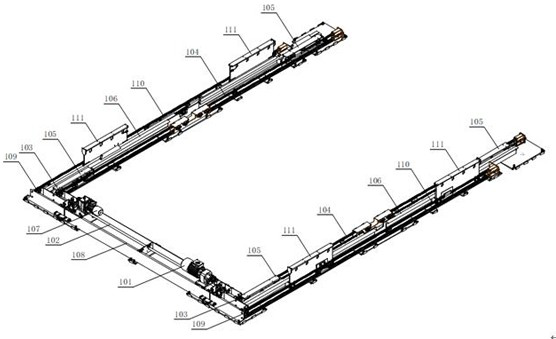

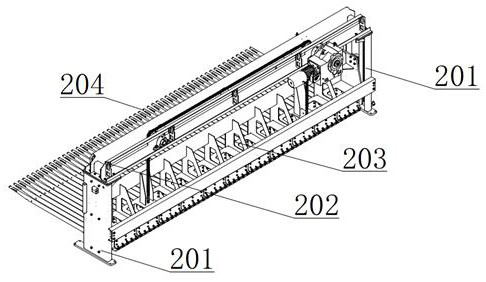

[0037] Such as figure 1 Shown: Tray automatic implantation device, 2-lifting part is installed on 105-lifting front and rear moving frame of 1-bottom driving part, two pieces in total, one piece on the left and right side of the roller conveyor I, and it is symmetrical about the corrugated cardboard conveying line ; 3-the centering part is installed on the 111-centering front and rear mobile frame of the 1-bottom drive part, two pieces in total, one piece on the left and right sides of the roller conveyor 1, and about 9-corrugated cardboard pile (before implanting the pallet) The conveying center line is symmetrical; 4-roller conveyor I is installed inside the frame of 1-bottom drive part, and the center line of 4-roller conveyor I coincides with the conveying center line of 9-corrugated cardboard stack (before implanting the pallet); 2-lift Part of the 204-fork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com