A three-dimensional braided preform radial yarn implantation mechanism

A technology for three-dimensional weaving and prefabrication, applied in the field of three-dimensional weaving machines, can solve the problems of restricting the automation of three-dimensional multi-directional weaving technology, difficult to ensure the consistency of prefabricated body quality, low weaving efficiency, etc., so as to reduce weaving time and reduce the impact of precision. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

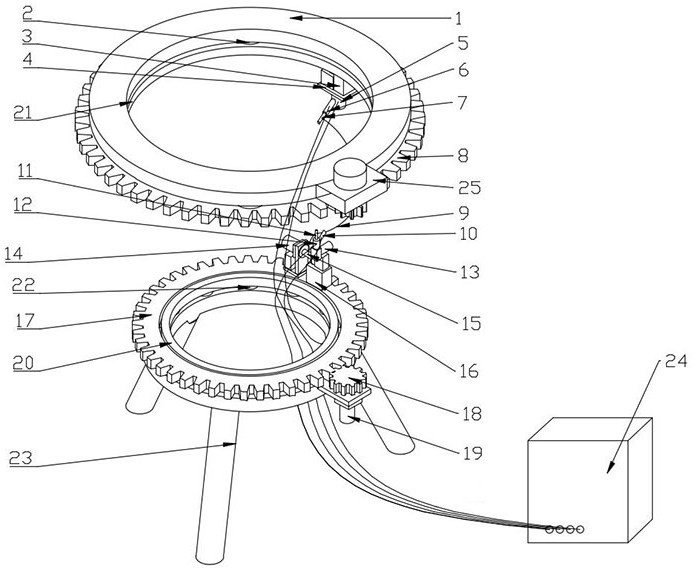

[0017] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings.

[0018] Such as figure 1 It is a structural schematic diagram of the radial yarn implantation mechanism of the three-dimensional braided preform of the present invention, and the radial yarn implantation mechanism of the three-dimensional braided preform includes: an upper support 1, an upper linear actuator, an upper support mechanism 4, an upper Side yarn implanting device 6, yarn end carrying device 7, upper ring gear 8, lower yarn implanting device 10, lower linear actuator, yarn tension control device 14, yarn storage device 15, bracket 16, Lower ring gear 17, lower gear 18, lower motor 19, lower ring track 20, upper ring track 21, base 23, upper gear, pneumatic transmission and control device 24 and upper motor 25; upper ring gear 8 is provided with an upper annular track 21, the upper part of the upper ring gear 8 is provided with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com