A method for dismantling and replacing the Y-type downcomer of a blast furnace

A replacement method and blast furnace technology, which is applied in the direction of dust collector, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of difficulty in hoisting when the Y-shaped downcomer of blast furnace is removed and replaced, so as to reduce the difficulty of hoisting and improve work efficiency. The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the accompanying drawings.

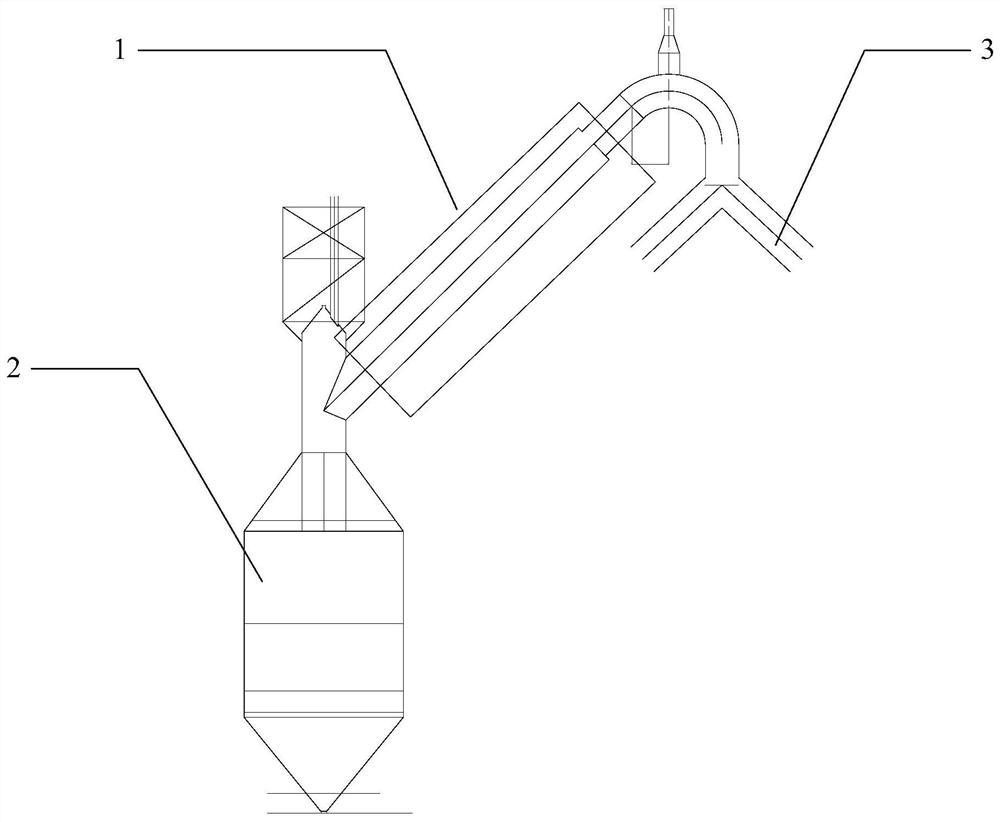

[0031] The blast furnace downcomer is the main part of the blast furnace ironmaking crude gas system, 1000m 3 The following blast furnace descending pipes usually use Y-shaped descending pipes 1, and the interior of the Y-shaped descending pipes 1 is provided with internal refractory materials. The forked end of the Y-shaped descending pipe 1 is connected to the blast furnace 3, and the end of the Y-shaped descending pipe 1 away from the blast furnace 3 is connected to the gravity dust collector 2, which is used for dedusting and purifying the crude gas produced by the blast furnace 3 during ironmaking. .

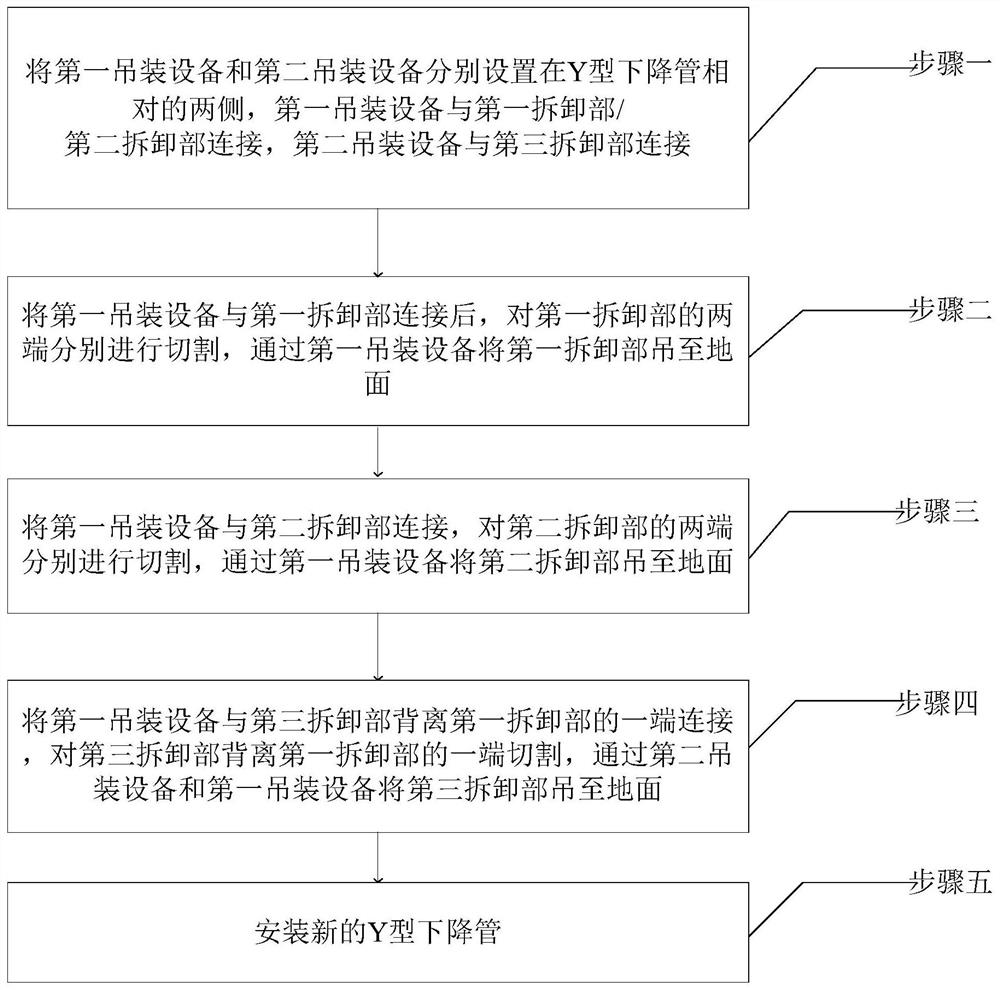

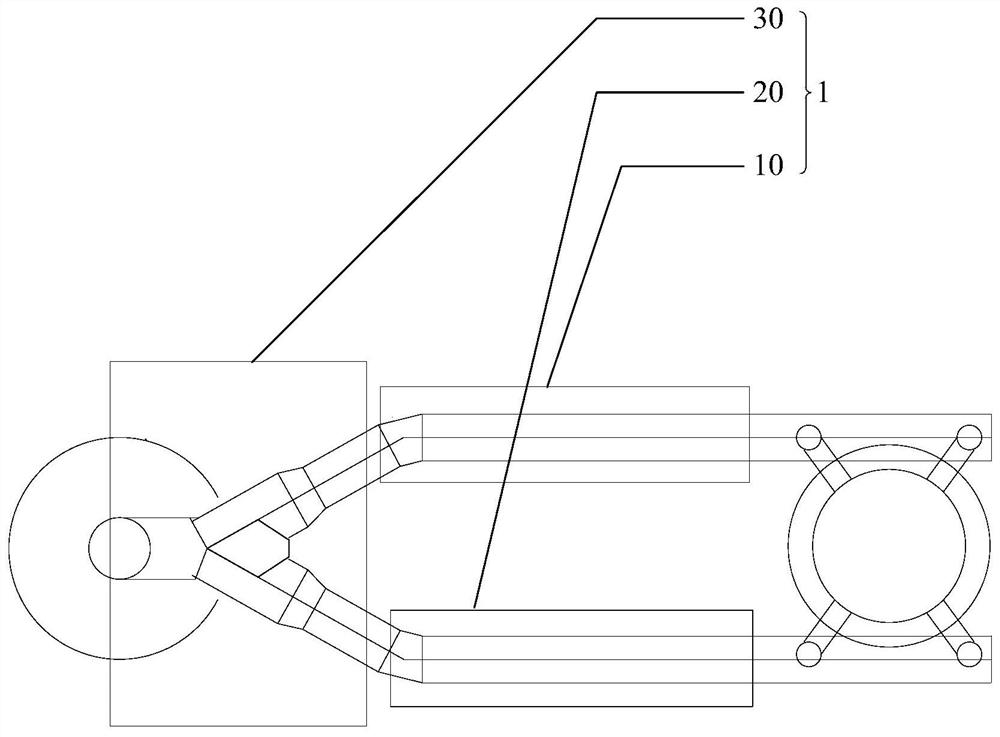

[0032] refer to Figure 2 to Figure 4 , which is a method for dismantling and replacing a Y-shaped descending pipe of a blast furnace disclosed in the present invention, comprising a Y-shaped descending pipe 1, a first hoisting device and a second hoisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com